Safety

Gemba Walk GPT: The Smartest Way to Turn Observations Into Real Improvement

Artificial Intelligence Continuous Improvement Lean Lean Manufacturing Lean Six Sigma Productivity Safety TPM World Class Manufacturing

A new digital solution is transforming the way teams run Gemba Walks by automating checklists, organizing observations, generating actions, and producing reports instantly. This post explores how the Gemba Walk GPT removes administrative waste and accelerates real, sustainable improvement.

Read More »Best Practices for Conducting a Risk Assessment

The first step in any risk assessment is identifying the organization's potential risks. This can include anything from equipment failures to cybersecurity breaches or natural disasters. Depending on the nature of the business, the risks can vary widely in terms of their likelihood and potential impact.

Read More »Understanding Unsafe Acts: Definitions, Dangers, and Prevention Measures

In this blog post, we will cover the fundamental aspects of safety, which include identifying unsafe conditions, unsafe actions, near misses, and accidents. It emphasizes the significance of acknowledging and managing potential hazards while emphasizing the importance of following safety protocols, using personal protective equipment, and adopting a safety-conscious culture.…

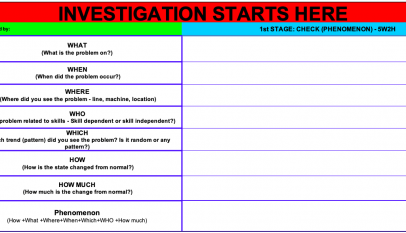

Read More »Safety, Health and Environment Investigation Report and Analysis

5 Why Analysis Blog Cap-Do Lean Six Sigma PM-analysis Root Cause Analysis Safety Safety, Health and Environment TPM

All modern manufacturing facilities use principles that “all accidents are preventable,” but sometimes incidents or accidents can still happen. Gathering as much data as possible and analyzing it to prevent a recurrence is essential. Investigation Report Let’s review the first part – [ Incident Reporting ] A. To be completed…

Read More »