Tools

Focused Improvement Training. CAP-Do and the 16 Major Losses

The packer was equipped with 12 obsolete pneumatic control valves...

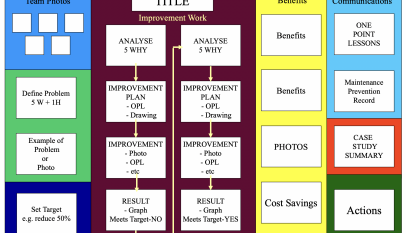

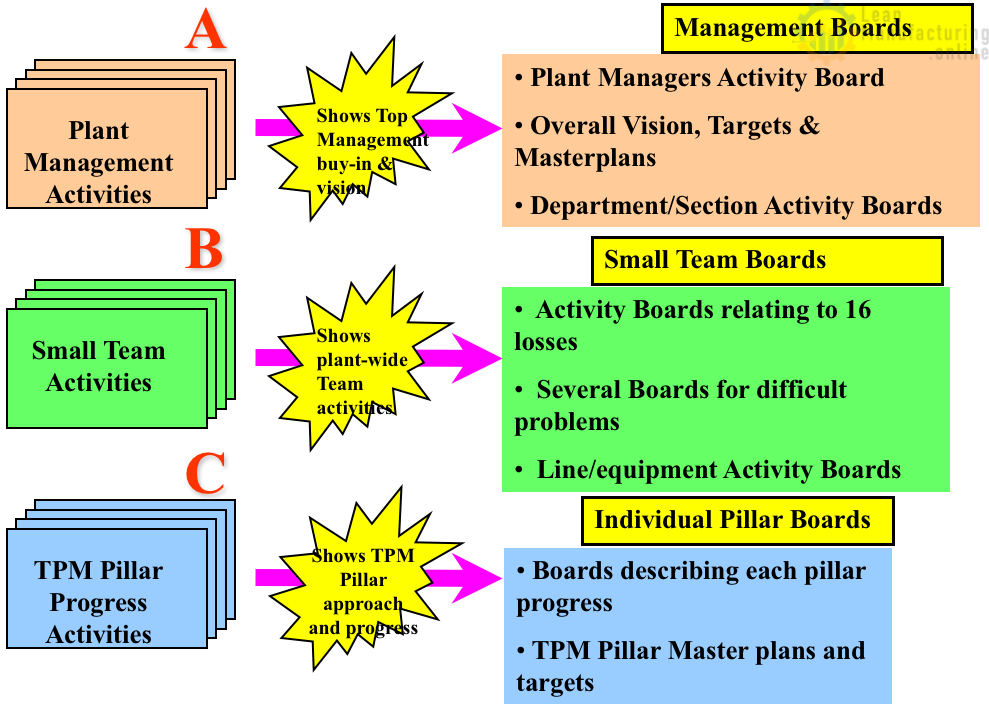

Read More »Activity Boards & Visual Management. Principles and Guide

Top Reasons for Failure: Boards not updated: discipline breakdown, lack of pride, low priority for TPM activities.

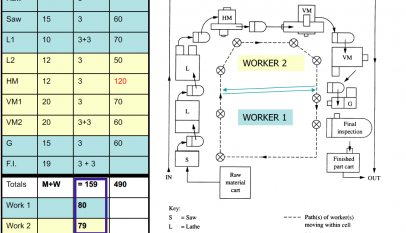

Read More »Introduction to the Toyota Production System (TPS)

Brief history of Manufacturing 1980’s OPEC oil embargo drives up fuel prices, Japan imports small cars with increased fuel mileage. How we learned about TPS Quality of cars – but not right awayPilgrimages – Hayes, Wheelwright, ClarkJoint ventures – Nummi-Geo…Japanese NA operations-Georgetown, KYJapanese sages- Ohno, Shingo, MondenAmerican translation – “Lean”,…

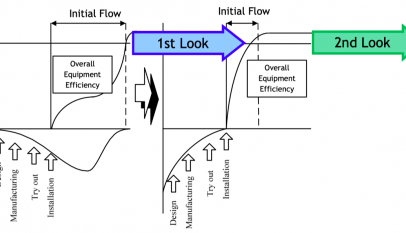

Read More »Application of FMEA for Root Cause Analysis

Failure Modes and Effects Analysis (FMEA) is one of the most effective analytic tools (methodology) to identify Potential Factors in a system, which is: Product or Design – to achieve the desired Quality Work System – Process Safety and Operational Efficiency Machine – Equipment Reliability and Maintainability, as well as…

Read More »