Root Cause Analysis

Root Cause Analysis Stacking: A Game-Changer for Problem Solving

Root Cause Analysis Stacking offers a structured method to streamline problem-solving by combining causal factor analysis and root cause identification. Learn how this approach improves accuracy, reduces errors, and supports better decision-making

Read More »Safety, Health and Environment Investigation Report and Analysis

5 Why Analysis Blog Cap-Do Lean Six Sigma PM-analysis Root Cause Analysis Safety Safety, Health and Environment TPM

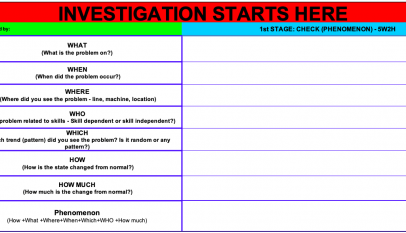

All modern manufacturing facilities use principles that “all accidents are preventable,” but sometimes incidents or accidents can still happen. Gathering as much data as possible and analyzing it to prevent a recurrence is essential. Investigation Report Let’s review the first part – [ Incident Reporting ] A. To be completed…

Read More »Application of FMEA for Root Cause Analysis

Failure Modes and Effects Analysis (FMEA) is one of the most effective analytic tools (methodology) to identify Potential Factors in a system, which is: Product or Design – to achieve the desired Quality Work System – Process Safety and Operational Efficiency Machine – Equipment Reliability and Maintainability, as well as…

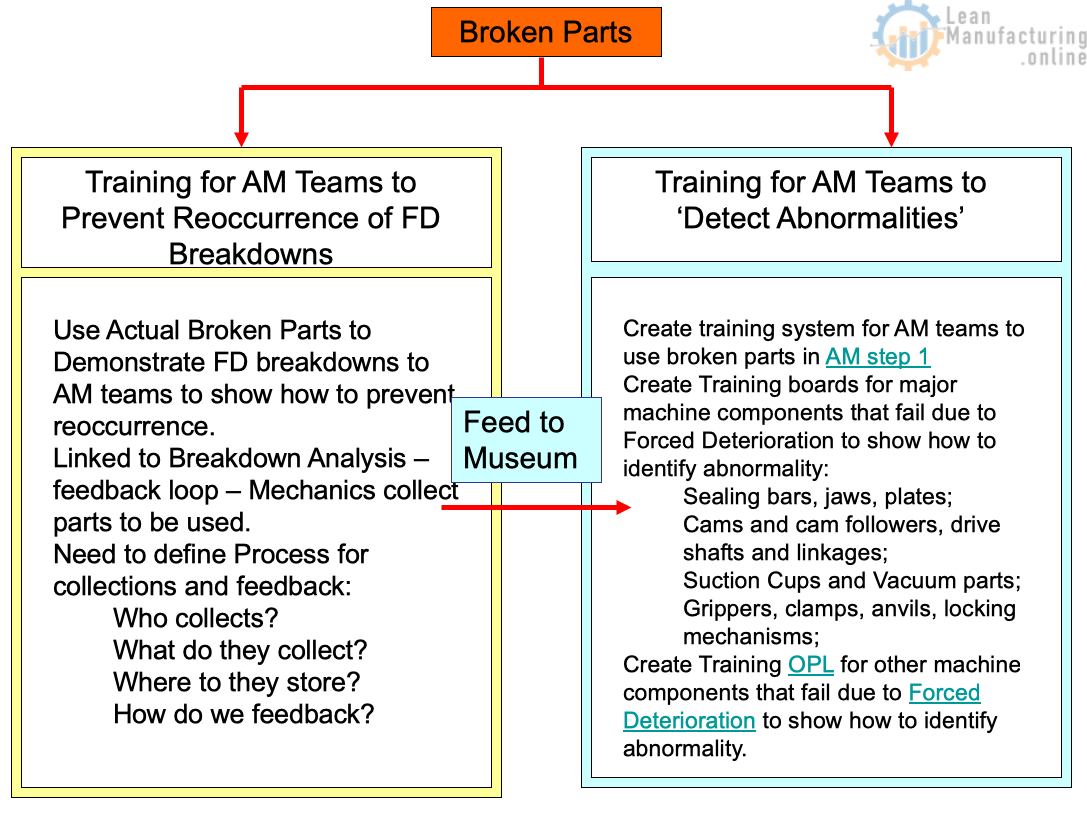

Read More »Broken Parts Museum – Analyzing and Preventing Breakdowns due to Forced Deterioration

5 Why Analysis Autonomous Maintenance Blog OPL Root Cause Analysis Training World Class Manufacturing

Collecting broken or worn machine parts for later analysis will help to understand root cause of failures, as well as can assist with training AM team members. Training for AM Teams to Prevent Reoccurrence of Forced Deterioration Breakdowns Use Actual Broken Parts to Demonstrate FD breakdowns to AM teams to…

Read More »