Autonomous Maintenance

Five Causes of Equipment Breakdowns

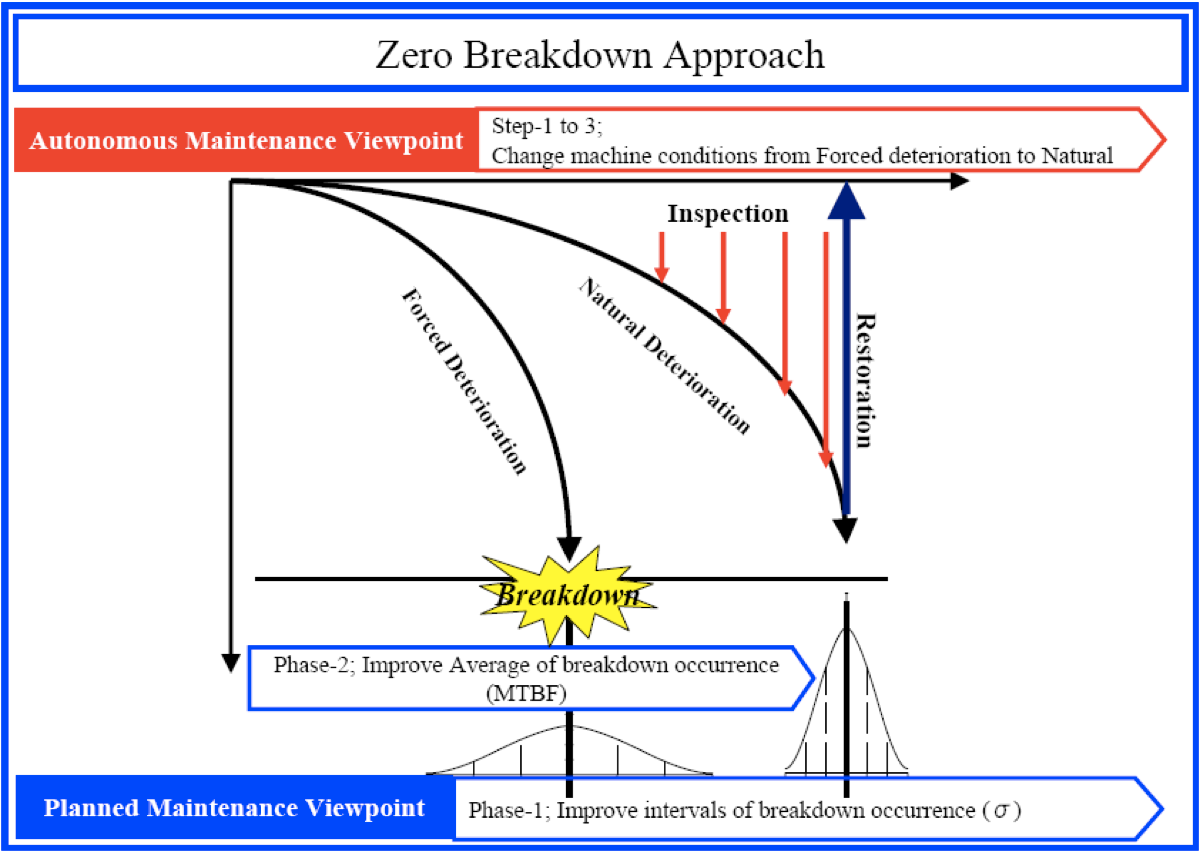

When equipment breaks down it is necessary to find root cause of the problem. Let’s review five main causes. Forced Deterioration These breakdowns are caused by: Lack of Cleaning (accumulation of Dirt and Dust);Lack of Inspection (e.g. loose nuts, bolts, etc);Lack of Lubrication. Lack of Basic Conditions (CIL) ! What…

Read More »Broken Parts Museum – Analyzing and Preventing Breakdowns due to Forced Deterioration

5 Why Analysis Autonomous Maintenance Blog OPL Root Cause Analysis Training World Class Manufacturing

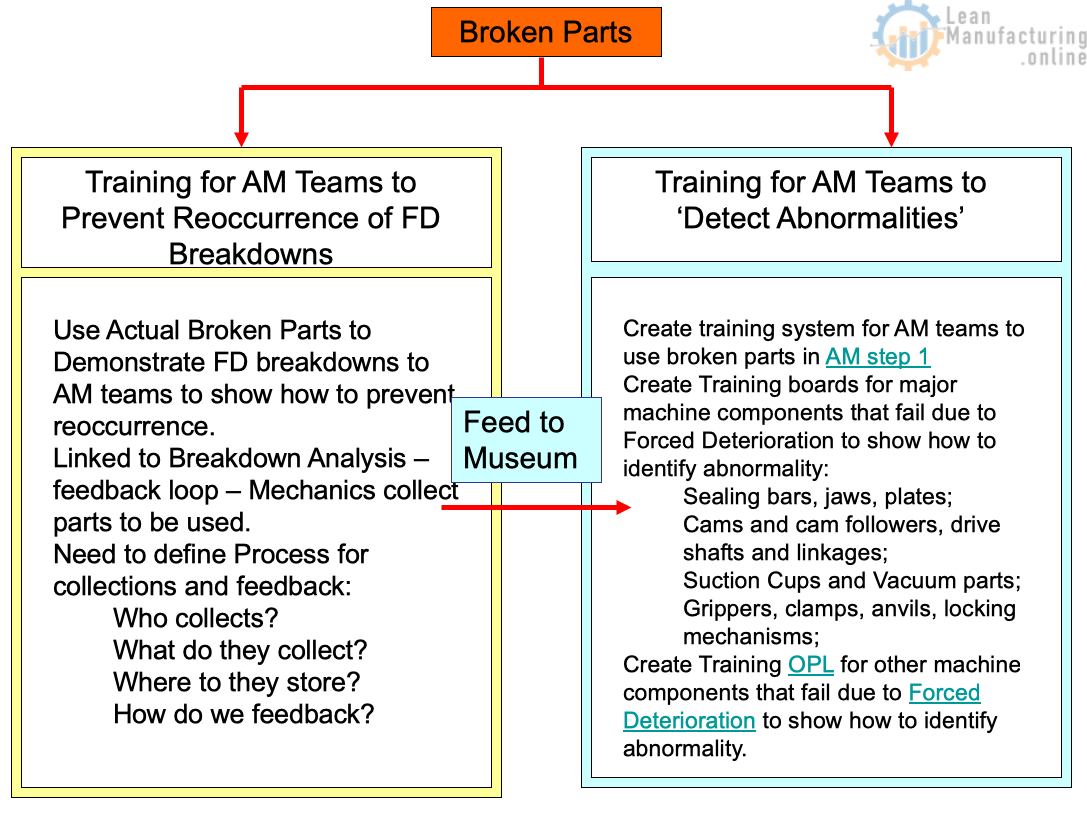

Collecting broken or worn machine parts for later analysis will help to understand root cause of failures, as well as can assist with training AM team members. Training for AM Teams to Prevent Reoccurrence of Forced Deterioration Breakdowns Use Actual Broken Parts to Demonstrate FD breakdowns to AM teams to…

Read More »Autonomous Maintenance Step 6 and 7 – Standardization and Autonomous Management

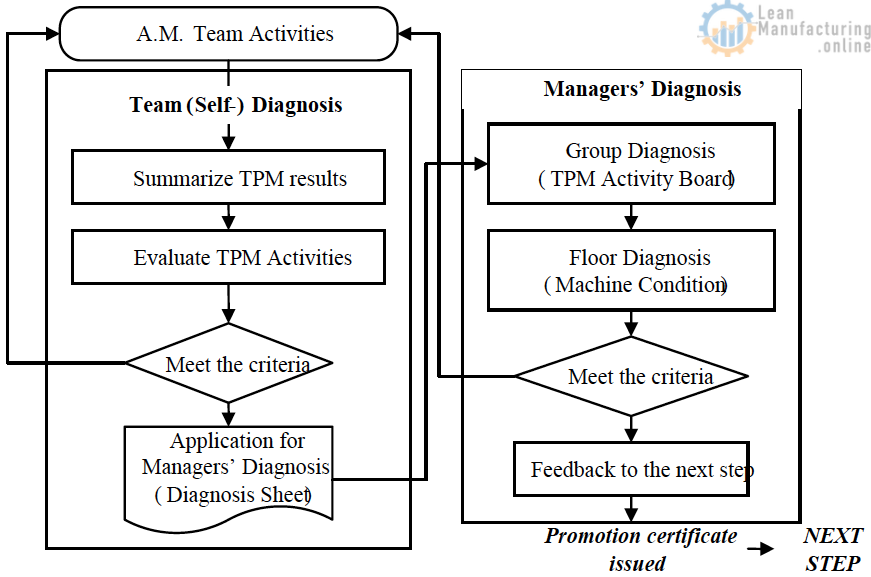

AM – Step 6 Activities – Standardization Objective Standardize Routine Operation to sustain & prevent Problems. Activities Develop Sub-step Activities 6.1 Quality 6.2 Change Over 6.3 Cyclic Operation 6.4 Safety Review the Role of Operators, and Efficiency Improvement and Standardization of Related Work Maintain an Effective Autonomous Inspection System AM – Step…

Read More »Autonomous Maintenance – Utilizing the Talents of Your “Experts” on GENBA

What is Autonomous Maintenance? Shop-floor based activities Operator conducted Operator enhancing Team activity Shop-floor Kaizen & TPM Foundation Part of the job! Concept of Productive Maintenance Phases in Autonomous Maintenance Why Autonomous Maintenance? Basic Concept of Autonomous Maintenance 7 Step Autonomous Maintenance Autonomous Maintenance is the activities designed to…

Read More »