Autonomous Maintenance

Autonomous Maintenance Step 0

What is Step 0? Step 0 is the Preparation Phase for AM, specifically with regard to Safety. Safety Comes First! Objectives of Step 0: 1.Ensure safe work practices in AM 2. Get better understanding of equipment 3. Learn TPM tools Ensuring Safe Work Practices Personal Protective Equipment (PPE) Identify Sources of…

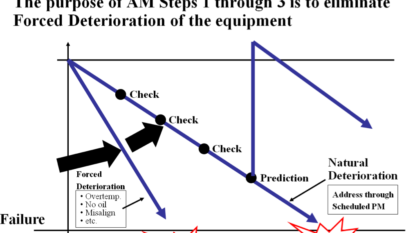

Read More »Forced vs. Natural Deterioration

Any item or system in a plant is usually designed to have a performance capability that is safely above that required to meet the duty demands. Consequently, there is some margin over which the performance can deteriorate before the process duty fails to be completed. The deterioration may be relatively…

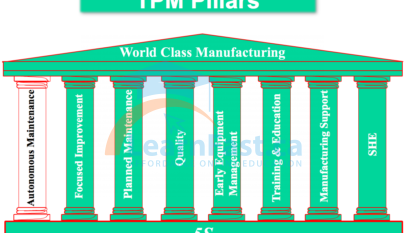

Read More »Autonomous Maintenance

AM is a New Way of Thinking & Working Old Approach I operate, You fixI fix, you designI design , you manageI manage, you… New Approach We are all responsible for our equipment Maintenance in TPM – AM Maintenance is not a person or group !Maintenance is the act of…

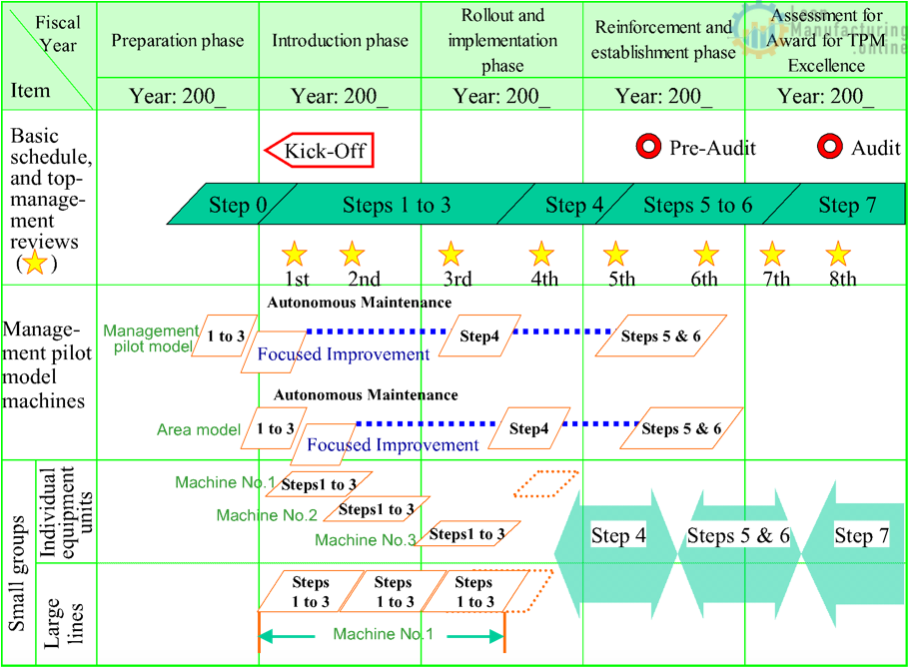

Read More »Autonomous Maintenance Model

1. Autonomous Maintenance Implementation Steps 7 steps to Autonomous Maintenance. Examples of steps to implement AM Step 1. Initial cleaning (cleaning and inspection) Complete elimination of waste and dirt, focusing on the equipment main body, implementation of lubrication and retightening, discovery of equipment problems and the restoration thereof. Step 2. Countermeasures for…

Read More »