Early Equipment Management

Best Practice Dosing for Savoury Dehydrated Products. Part 2

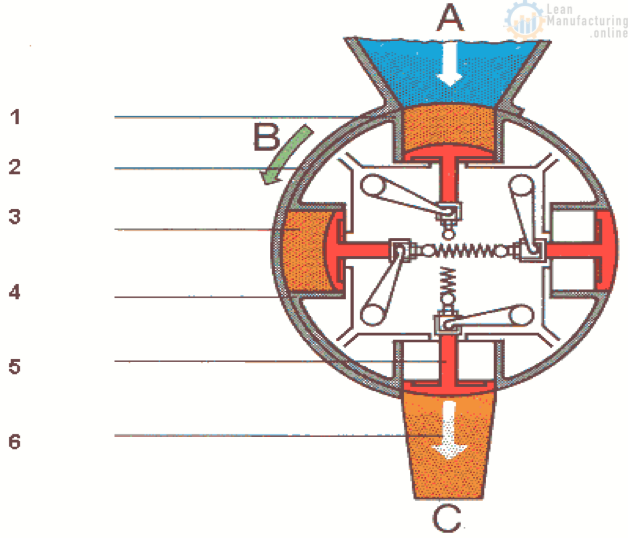

3.2.5. Sliding gate (tube) dosing unit Like the sliding gate flat dosing unit, the sliding gate tube dosing unit utilises a sliding gate product cut off to dispense quantities of product. The accuracy of this type of dosing unit is limited and it is often used for larger particulates. Sliding…

Read More »Best Practice Dosing for Savoury Dehydrated Products

Dosing is one of the most important manufacturing process steps for dehydrated products for any dry food packaging facility. It has a major influence on consumer quality and perception and an important influence on cost. When dosing isn’t done properly, i.e. with the wrong equipment or parameter settings, it will…

Read More »Chapter 7. Early Equipment Management. Part 3

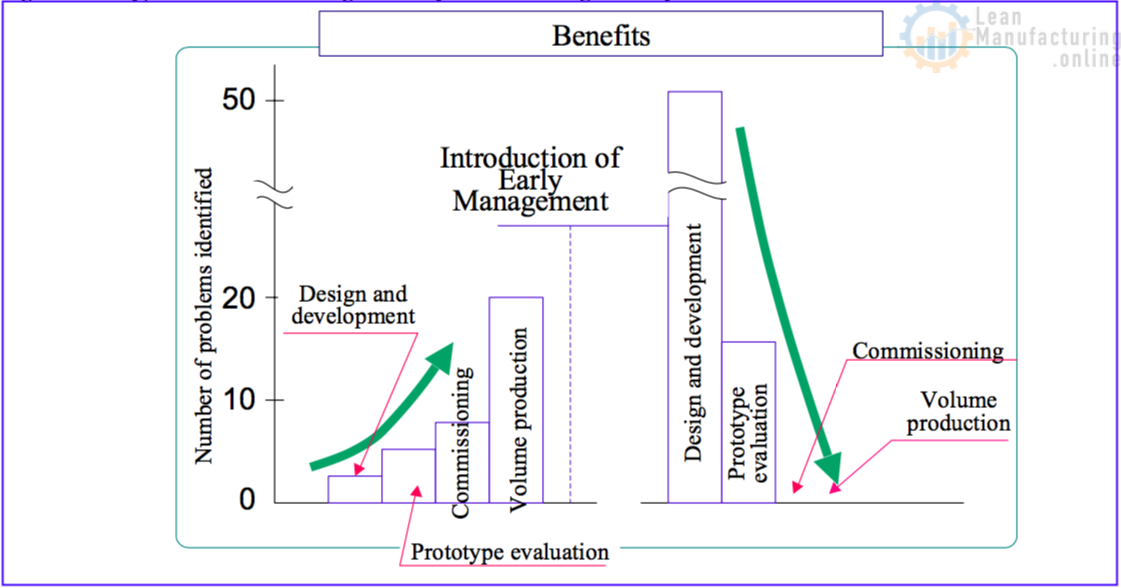

5.2 What is ‘MP Design’? 6. Implementing Early Equipment Management Step by Step 6.1 The 7 steps for rolling out an Early Equipment Management system 6.2 A typical action planning stage of Early Equipment Management 6.3 What happens at the design stage 6.3 An overview of MP design at Steps…

Read More »Chapter 7. Early Equipment Management. Part 2

4. Early Product Management 4.1 The objective of an Early Product Management system 4.2 Basic approach 4.3 A typical implementation 4.4 Designing-in factory-friendliness at the product development stage 4.5 Building in quality through control of first-of-run products 4.6 Making use of information on problems arising during Early Product Management 5.…

Read More »