4. Early Product Management

4.1 The objective of an Early Product Management system

4.2 Basic approach

4.3 A typical implementation

4.4 Designing-in factory-friendliness at the product development stage

4.5 Building in quality through control of first-of-run products

4.6 Making use of information on problems arising during Early Product Management

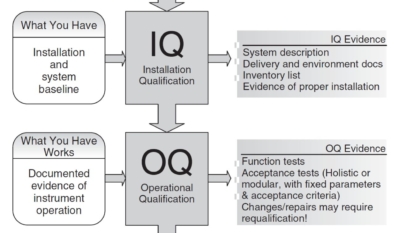

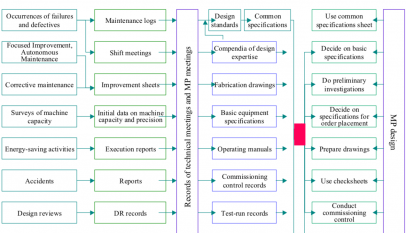

5. Early Equipment Management

5.1 Attaining business objectives by using equipment efficiently

Chapter 7. Early Equipment Management. Part 3