Early Equipment Management

The Objectives of Early Management

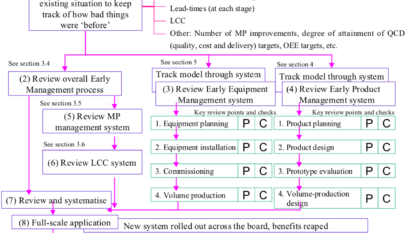

Why is Early Management necessary? Because 80% of the LCC (life-cycle cost) of products and equipment is determined at the design stage.Because Early Management program the whole service life of the product or equipment, at the design stage. Early Management boils down to the endeavour to create factory-friendly equipment and…

Read More »The Four Steps to Early Management Implementation

To train your staff and fine-tune the system, try it out on sufficient pilot projects for everyone to take part, at the right level of difficulty for the design engineers.

Read More »Early Management

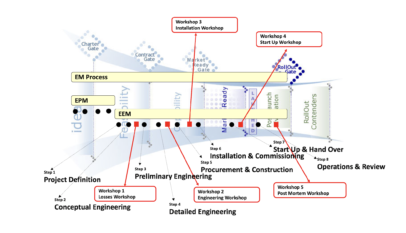

Product planning has to be preceded by market research. In this manual, the blanket term “management of product and equipment development”, or “development management”, will be used to refer to all the activities taking place from the market research stage onwards. In the early stages of TPM (Level 1), development…

Read More »TPM 3 Levels – path to World-Class Manufacturing

5S Autonomous Maintenance Blog Change Management Early Equipment Management Early Product Management Education and Training Focused Improvement Instructor Training Manufacturing Support Planned Maintenance Quality Safety, Health and Environment TPM TPM Introduction World Class Manufacturing

Getting to Level 3 of Total Productive Maintenance will require a LOT OF hard work, but it’s doable. Listed below is a 20-Step process on how to get there, steps 1-12 are part of Level 1 (Excellent Factory), steps 13-17 – Level 2 (Excellent Supply Chain) and finally, steps 18-20…

Read More »