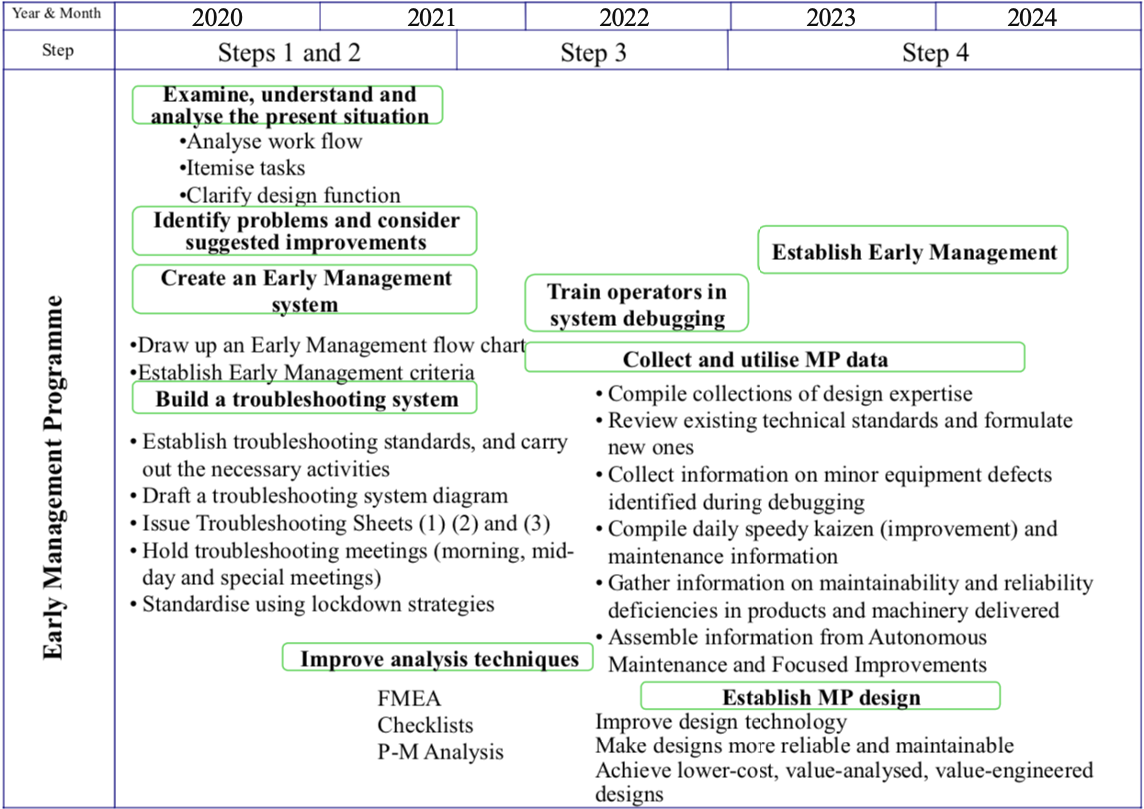

Step 1: Examine and analyze the present situation

Figure “Example of an Early Management Rollout” shows a recommended procedure for thorough and effective implementation of Early Product and Equipment Management.

Examine and analyze the current situation (i.e. how Early Management has been carried out for the past year or two), and clarify the problems.

- Clarify the current Early Management workflow.

- Identify the problems with the current workflow.

- Find out what is currently being done to ‘design out’ foreseeable problems at each stage of the Early Management process.

- Find out what problems are currently arising at the prototyping, test-run and commissioning stages, and what is being done about them.

- Find out how the process is being held up at the prototyping, test-run and commissioning stages.

- Find out what is currently being done in the way of collecting, storing and using information with a view to designing products and equipment to be user-friendly, factory-friendly, non-defective-generating, maintenance-friendly and highly-reliable, as well as safe and commercially-competitive.

Step 2: Establish an Early Management system

In the light of all the knowledge gained from the previous stage, build a new system aimed at making Early Management work the way it should.

- Think through a basic Early Management system, set it up, and define the scope of its application.

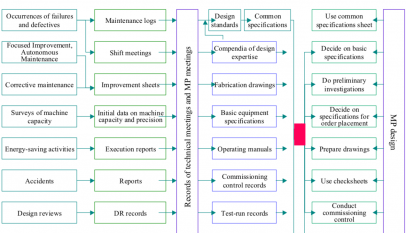

- Think through and set up a system for collecting, collating and utilizing the data needed for Early Management.

- Formulate and refine the various standards and forms needed to run these systems.

Step 3: Debug the new system, and train your workforce to use it

To train your staff and fine-tune the system, try it out on sufficient pilot projects for everyone to take part, at the right level of difficulty for the design engineers.

- Implement the system progressively, taking one project at a time, and one Early Management stage at a time.

- Meanwhile, train everyone in the standard techniques needed to implement the system.

- Throughout each step, keep evaluating everyone’s understanding of the new system, and keep reassessing the techniques being used, the effectiveness of what is being done to build quality into the design, and so on. Treat the debugging process as a diagnostic technique.

- In the light of your new knowledge, refine the system, the standards and the forms used.

- Take stock of the benefits you have gained by using the new system.

Step 4: Bring the new system into full-scale operation

- Bring the new system into full-scale operation by extending it to all areas.

- Arrange for more of the information generated to be channelled into LCC (life cycle cost) optimization and MP (maintenance prevention) design as a matter of course.

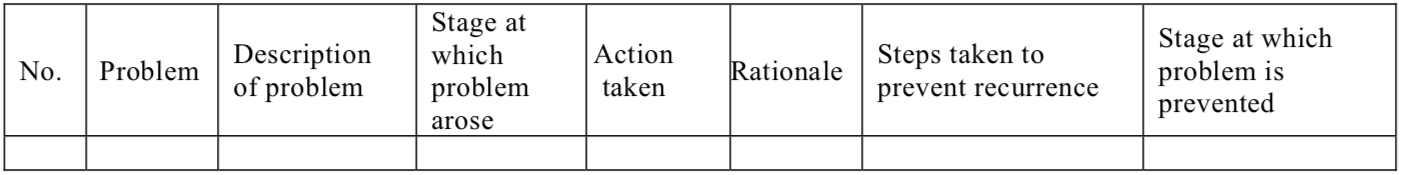

- Identify the problems in each area and at each stage of Early Management. Find out how many improvements were incorporated into the design, how many problems are arising, what types of problem they are, how long the delays are, and so forth. Collate all the data and take stock of results every six months or every year. Analyse the problems arising from the commissioning stage onwards, consider how things could be put right at an earlier stage, and press ahead with standardisation, aiming for a vertical startup right on schedule.