Education and Training

Training Module for Manufacturing Sites

Training is an essential part of any manufacturing facility. Whether it’s TPM training or regulatory, we got it covered. Down below you will find the table with training modules by a pillar, the approximate duration of the training session and refresher frequency. TRAINING/ABILITIESTPM PILLARDURATIONREFRESHERSHE PILLAR CONFINED SPACE AWARENESSSHE.25 H1 YEARBLOODBORNE PATHOGENS/INCIDENT…

Read More »Autonomous Maintenance Step 5. Autonomous Inspections

Achieving Higher Levels of RELIABILITY and MAINTAINABILITY Maintain the restored state of equipment achieved through Steps 0-4 and Document Results of reduction in cleaning time; Further raise the reliability, maintainability, and quality of equipment; Develop and implement “Theory of Operation” manuals for each piece of equipment; Improve the efficiency of…

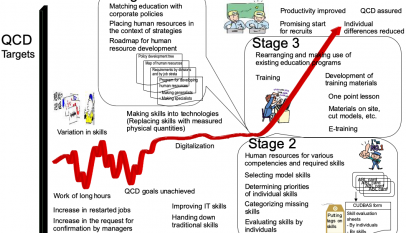

Read More »Creation of a System for Education and Training

Necessity of Education Necessity for Improving Knowledge and Skills in Operation and Maintenance Abilities Required for Machine Operators Ability to detect and repair malfunctions of equipmentAbility to comprehend the functions and mechanisms of equipment and discover systematic causes of abnormalitiesAbility to comprehend the relationship between equipment and product qualities, predict…

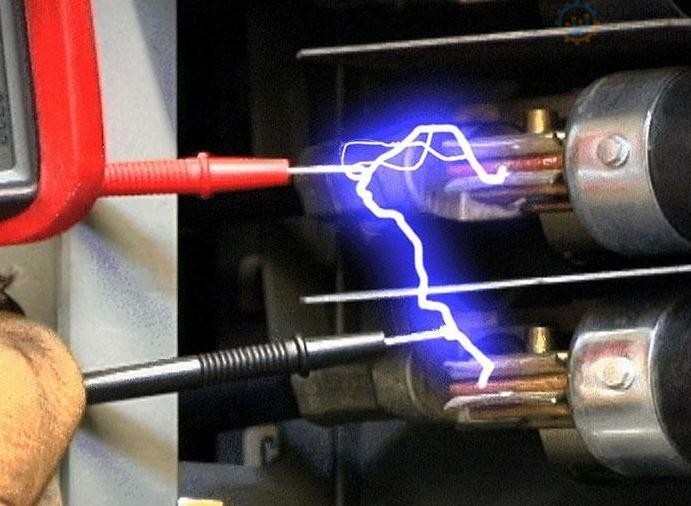

Read More »Electrical Arc Flash Hazards ‘Awareness’ Training

Electrical Arc Flash Safety Every year many workers are treated in hospitals with major injuries related to the arch flash. The flash is instantaneous, the effects of it can last forever and be very traumatizing. What is an Arc Flash? “…a dangerous condition associated with the release of energy caused by an…

Read More »