Focused Improvement

The Basic Thinking behind Focused Improvement

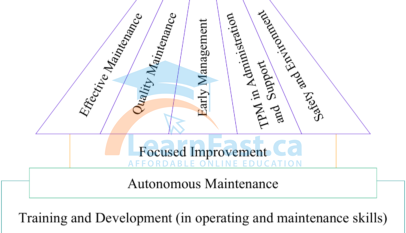

It is best to address each type of loss under the most appropriate pillar, with Effective Maintenance focusing on eliminating failures, TPM in Administrative and Support Departments focusing on attaining zero administrative losses, and so on.

Read More »TPM 3 Levels – path to World-Class Manufacturing

5S Autonomous Maintenance Blog Change Management Early Equipment Management Early Product Management Education and Training Focused Improvement Instructor Training Manufacturing Support Planned Maintenance Quality Safety, Health and Environment TPM TPM Introduction World Class Manufacturing

Getting to Level 3 of Total Productive Maintenance will require a LOT OF hard work, but it’s doable. Listed below is a 20-Step process on how to get there, steps 1-12 are part of Level 1 (Excellent Factory), steps 13-17 – Level 2 (Excellent Supply Chain) and finally, steps 18-20…

Read More »Focused Improvement Pillar OEE Losses Definition

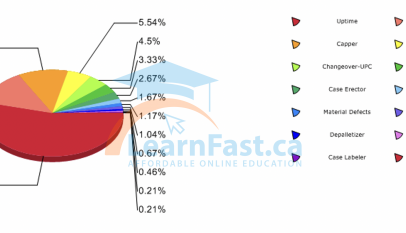

Problems in the Current Process Too many people and systems manipulate the informationAll unaccounted downtime is charged to minor stopsDowntime Losses + OEE hardly close to 100%Open spreadsheet to calculate OEEConcepts are not well understood by those entering the informationAdjustments in the OEE Losses Tree are made at the end…

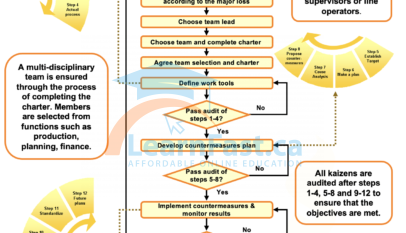

Read More »12-Step Kaizen Story

The Key Tool for Executing Continuous Improvement 12-Step Kaizen is a Better Defined CAP-Do Check Identify where the losses are Justify the subject selection by stratifying the data Understand the process and equipment Grasp the actual situation (Identify the Phenomenon) Establish the objective Establish a Work Plan Analyze Determine Root…

Read More »