The effects of much conventional improvement activity used to be transitory, and there was a strong tendency for improvements not to be capable of being sustained or properly established.

In TPM, by contrast, activities are organized to ensure that the benefits of Focused Improvements are upheld, principally through Autonomous Maintenance.

To keep our companies’ results perpetually trending upwards, we need two abilities: the ability to sustain and improve: moreover, it is essential to strike the right balance between the two. Even if we excel in one, it will be difficult to achieve better and better results over the long term unless we also excel in the other. Focused Improvement is a program of activities designed to foster the second of these two abilities: improving while delivering tangible financial benefits. Its aim is to greater production efficiency, and its main thrust is dramatically increasing productivity by eliminating the 16 Big Losses.

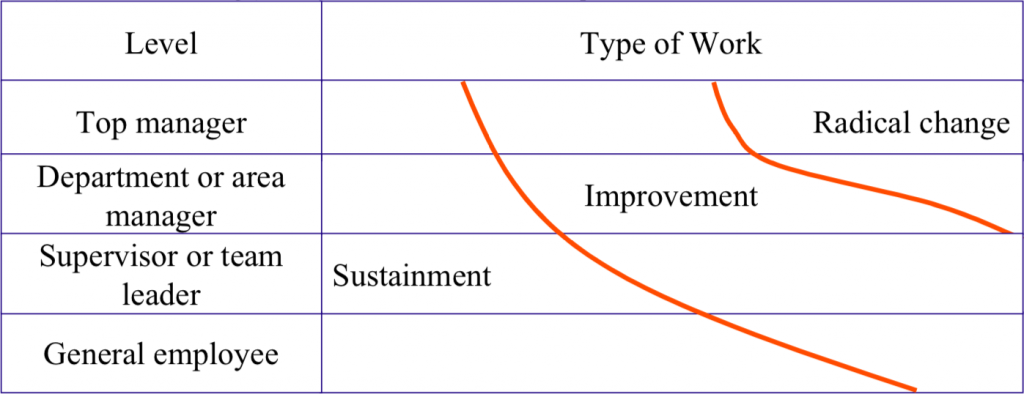

In contrast, Autonomous Maintenance is a program of activities that leans towards fostering the first of the two abilities, the ability to sustain, giving the shop floor a solid underpinning that makes it possible to uphold the benefits of Focused Improvement and other initiatives over the long term. The balance between the amount of sustainment work and improvement work (and also of radical change-related work) a person does will depend on his or her position in the company hierarchy, as illustrated in Figure “How the Balance between Sustainment, Improvement and Radical Change Varies with Position on the Corporate Ladder”.

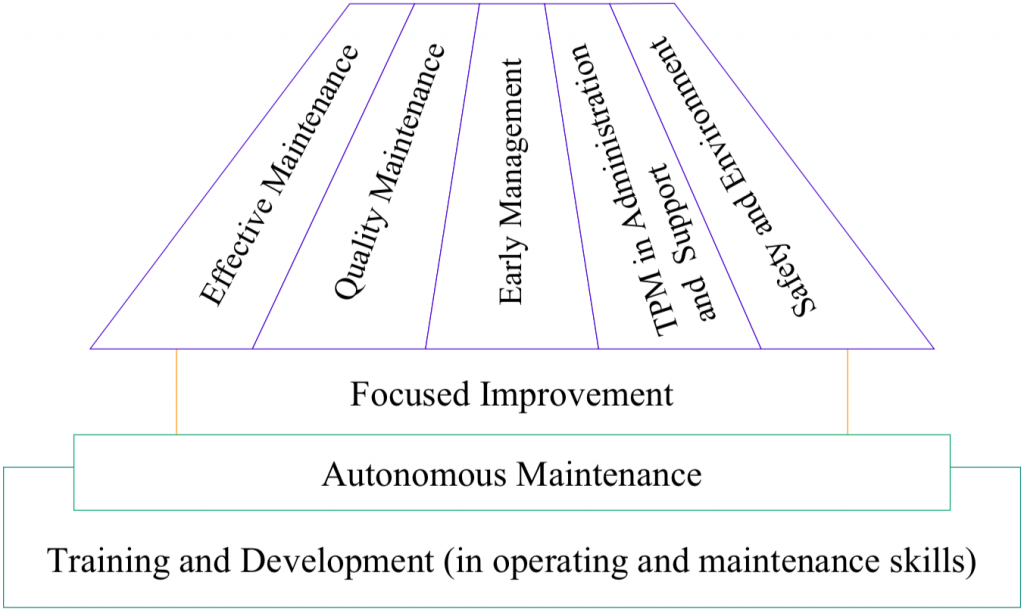

Also, while Autonomous Maintenance aims to build a system in which operators look after their own equipment, and Quality Maintenance aims to establish and manage the conditions for ensuring zero quality defects, Focused Improvement is how these aims are achieved. Focused Improvement, therefore, fits with the other TPM pillars in the way shown in Figure “How Focused Improvement Fits with the Other TPM Pillars”.

It is best to address each type of loss under the most appropriate pillar, with Effective (Planned) Maintenance focusing on eliminating failures, TPM in Administrative and Support Departments focusing on attaining zero administrative losses, and so on.