Instructor Training

Chapter 8. Quality Maintenance. Part 2

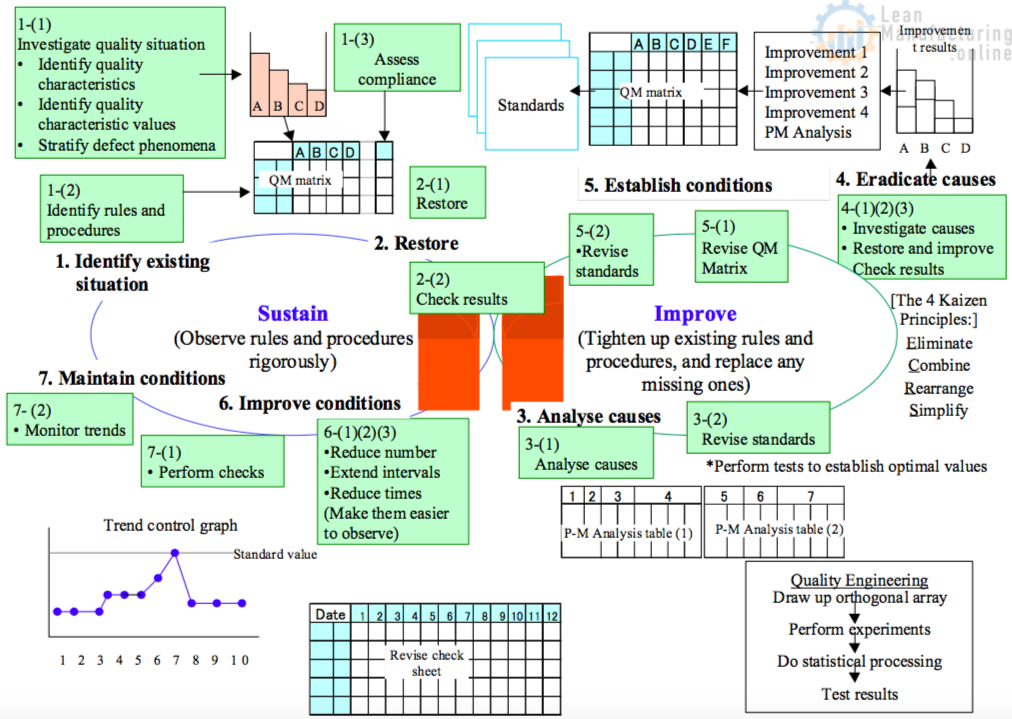

6. The Figure-of-Eight Method for Quality Maintenance 6.1 The History of Quality Maintenance and the Emergence of the Figure-of-Eight Method 6.2 The Figure-of-Eight Method: Basic Concepts and Development Steps 7. Quality Maintenance in a Manual Operation

Read More »Chapter 7. Early Equipment Management. Part 3

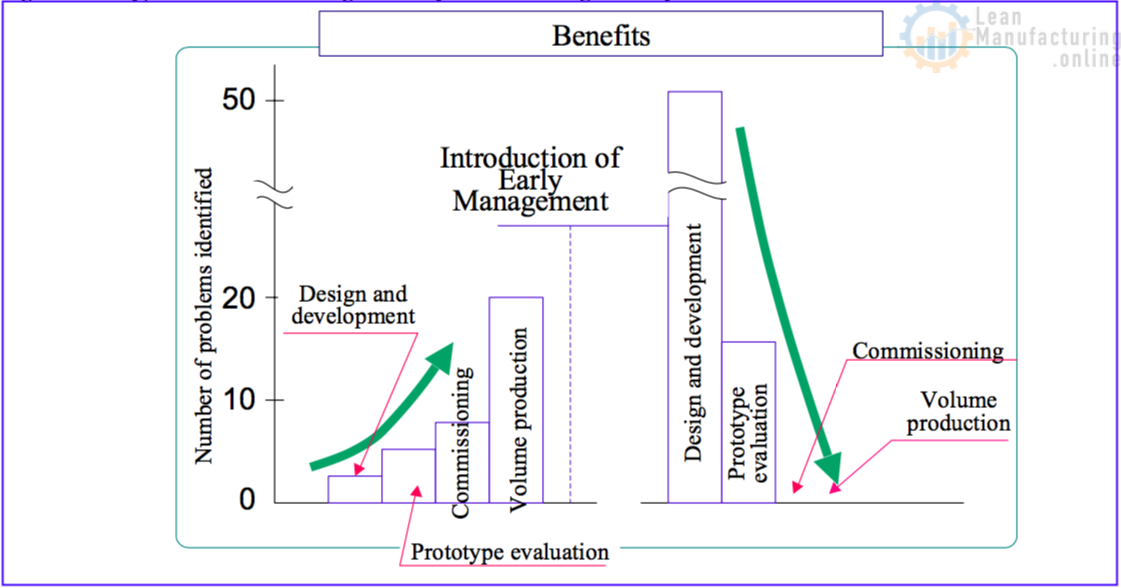

5.2 What is ‘MP Design’? 6. Implementing Early Equipment Management Step by Step 6.1 The 7 steps for rolling out an Early Equipment Management system 6.2 A typical action planning stage of Early Equipment Management 6.3 What happens at the design stage 6.3 An overview of MP design at Steps…

Read More »Chapter 7. Early Equipment Management. Part 2

4. Early Product Management 4.1 The objective of an Early Product Management system 4.2 Basic approach 4.3 A typical implementation 4.4 Designing-in factory-friendliness at the product development stage 4.5 Building in quality through control of first-of-run products 4.6 Making use of information on problems arising during Early Product Management 5.…

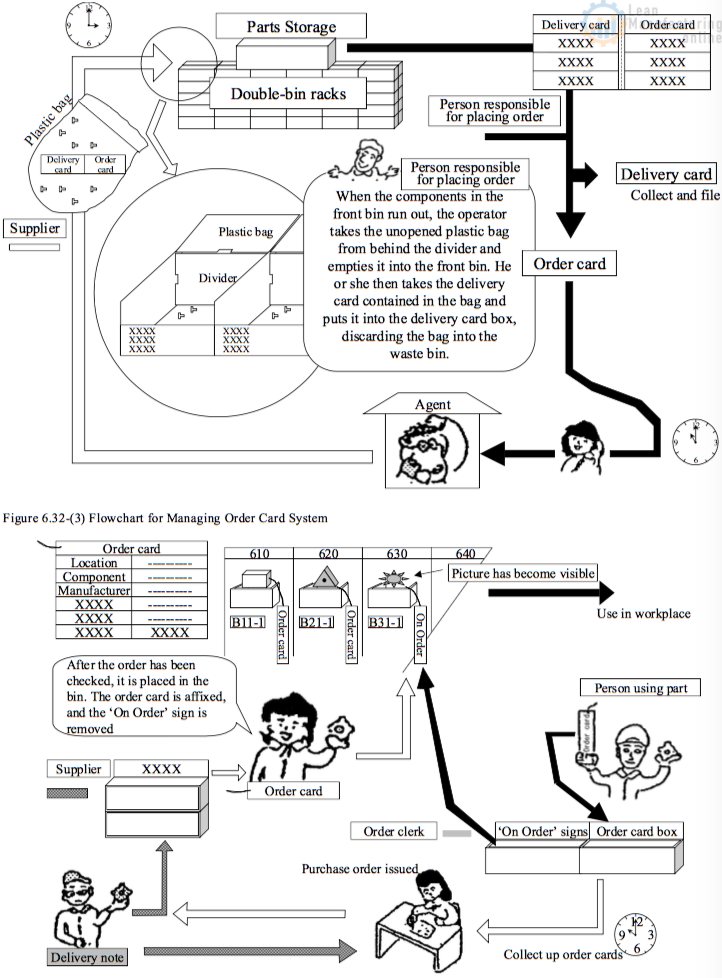

Read More »Chapter 6. Planned (Effective) Maintenance. Part 4

5. The 7 Steps of Effective Maintenance 5.3 Horizontal Replication of Equipment Management and Quality Management to Other Lines 6 Activities within Effective Maintenance 6.1 Examples of Activities within Effective Maintenance 6.2 A System for Maximising Production Effectiveness Figure 6.29 Example of a System For Maximising Production Effectiveness 6.3 Spare…

Read More »