July 19, 2024

0 361

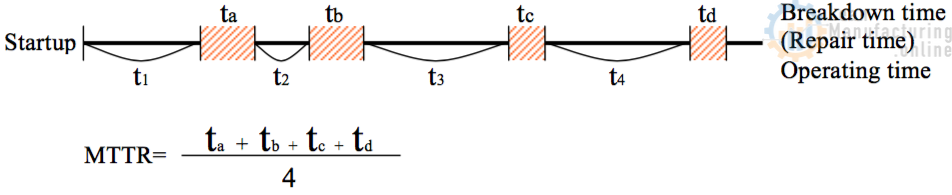

Unlocking Key Maintenance Metrics

June 15, 2024

0 626

Enhance Your Equipment Reliability with Preventive Maintenance

June 14, 2024

0 470

A Four-Step Guide to Reducing Maintenance Expenses

June 14, 2024

0 780

Essential Quality Tools for Effective Process Improvement

December 17, 2021

1 7,983

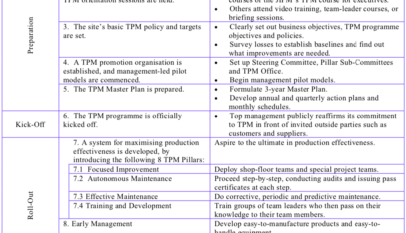

Getting Ready for TPM

September 15, 2021

0 3,288

Chapter 12. Completing and Upgrading the TPM Programme (Levels 1, 2 and 3). Part 1

5S

Autonomous Maintenance

Blog

Change Management

Early Equipment Management

Early Product Management

Education and Training

Focused Improvement

Instructor Training

Manufacturing Support

Planned Maintenance

Quality

Safety, Health and Environment

TPM

TPM Introduction

World Class Manufacturing

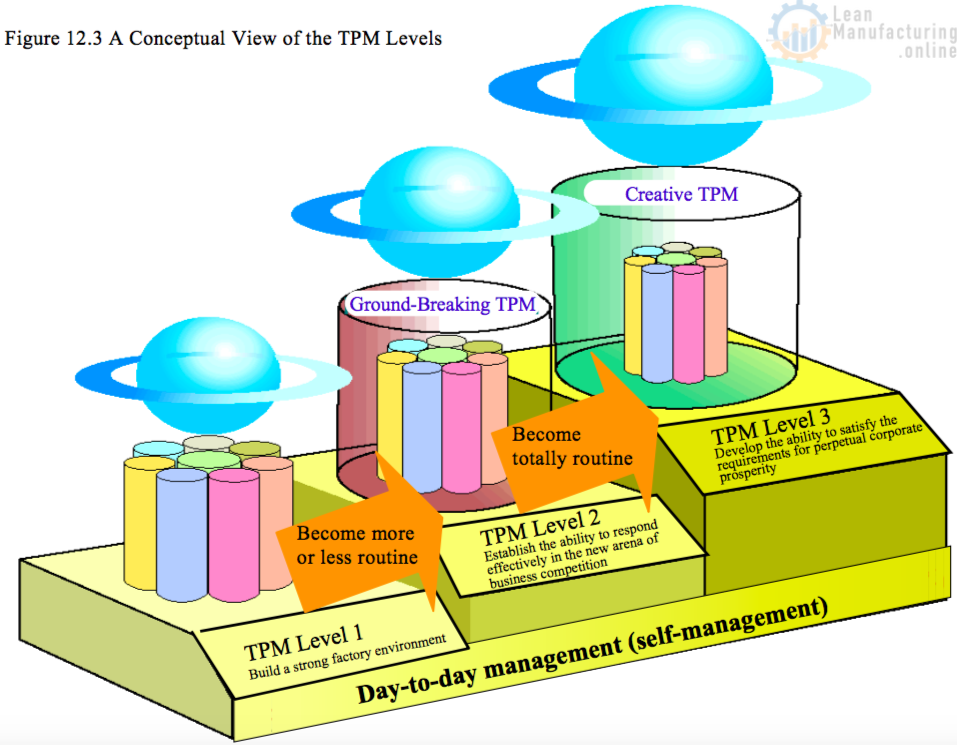

April 30, 2021

0 17,761

TPM 3 Levels – path to World-Class Manufacturing

December 1, 2020

0 2,356

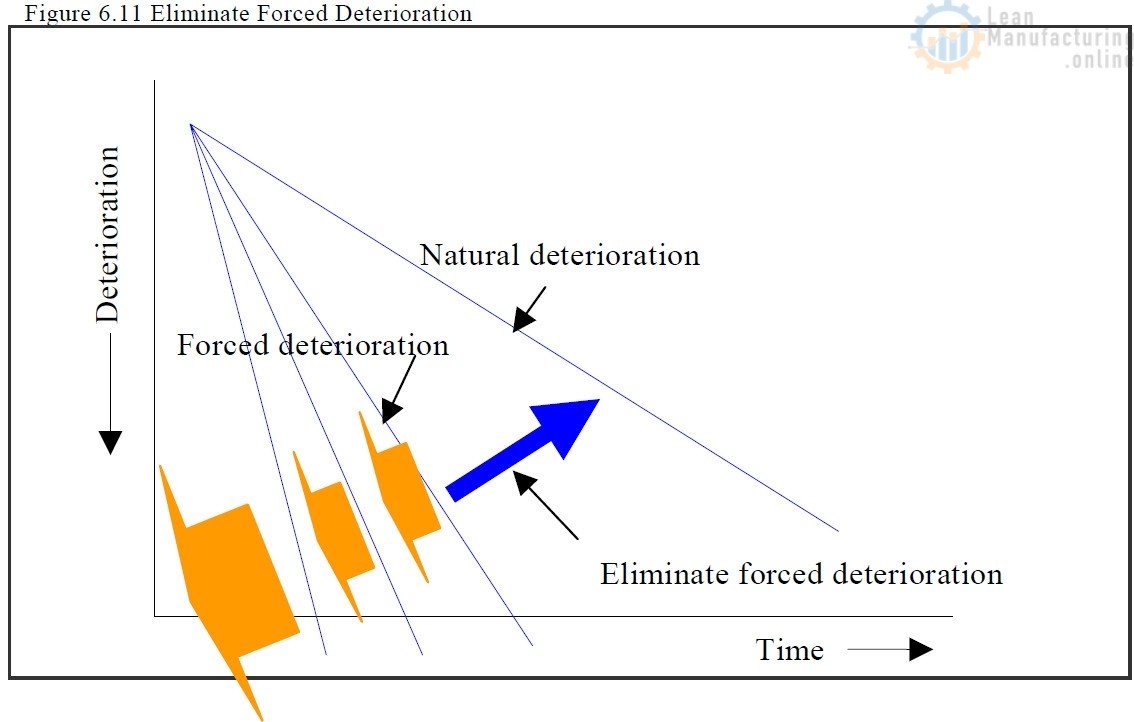

Chapter 6. Planned (Effective) Maintenance. Part 3

December 1, 2020

0 2,186

Chapter 6. Planned (Effective) Maintenance. Part 2

December 1, 2020

0 6,115

Chapter 6. Planned (Effective) Maintenance. Part 1

Most Popular

4M Analysis Process

The purpose of this procedure is to define the steps to do a 4M …

Very interesting article. I want to know who developed the methodology of Figure of 8? I heard that the concept was created for a Japanese Engineer named Kimura. Can you help me with this question?

Thanks for your question. Methodology was developed by Japanese Institute of Planned Maintenance (JIPM), Yoshifumi Kimura was one of the authors, he also developed the TPM program at Nachi-Fujikoshi. Hope this will help with your research.