TPM

5S Audit Checklist and Report

Randomly scheduled audits for compliance are essential to sustain a 5S environment. Frequency of audit dependent on “traffic”, “risk”, demonstrated compliance (sustaining efforts, past audits), etc.

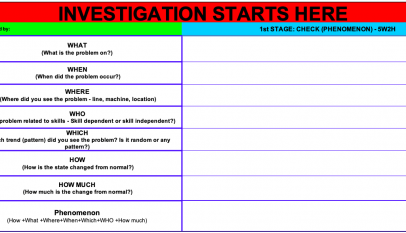

Read More »Safety, Health and Environment Investigation Report and Analysis

5 Why Analysis Blog Cap-Do Lean Six Sigma PM-analysis Root Cause Analysis Safety Safety, Health and Environment TPM

All modern manufacturing facilities use principles that “all accidents are preventable,” but sometimes incidents or accidents can still happen. Gathering as much data as possible and analyzing it to prevent a recurrence is essential. Investigation Report Let’s review the first part – [ Incident Reporting ] A. To be completed…

Read More »Detailed Autonomous Maintenance (AM) Master Plan. Steps 1 – 5

General Activities Setup Facilitator Practice sessionDevelop Minor Stop benchmark by lineCreate a standard Activity Board format and roll it out across the plantCreate audit templates for each stepSet up a feedback loop for Breakdowns (BD) to AM inspectionsDevelop skills matrix for pilot line teamAutomate Cleaning Inspection Lubrication (CIL) standardsInvolve operators…

Read More »The five steps towards visible Health and Safety Leadership

One Point Lessons are short visual presentations on a single point that sharpen job-related knowledge, easily share important information just-in-time Improve skills by communicating information about specific problems and improvements Spot check forklifts, hoists, and onsite permit to work – at least one/shift. Employees will see that you are engaged.…

Read More »