Planned Maintenance

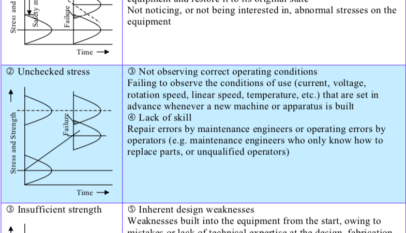

The Three Main Reasons Why Equipment Fails

Weaknesses built into the equipment from the start, owing to mistakes or lack of technical expertise at the design, fabrication or installation stages.

Read More »Planned Maintenance Indicators

(1) Failure Frequency “Failure frequency” denotes the incidence of failure as a percentage of loading time (the time during which the equipment is supposed to be operating). The “frequency” part of this term was borrowed from the discipline of safety management. The following formula expresses this index: (2) MTBF (Mean…

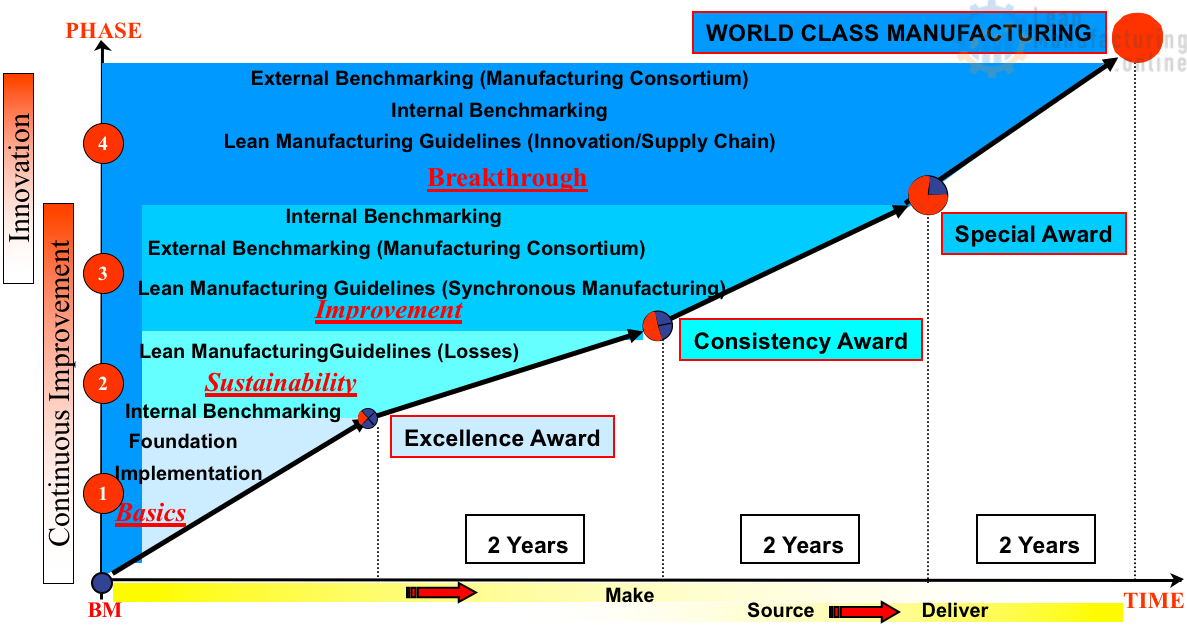

Read More »TPM 3 Levels – path to World-Class Manufacturing

5S Autonomous Maintenance Blog Change Management Early Equipment Management Early Product Management Education and Training Focused Improvement Instructor Training Manufacturing Support Planned Maintenance Quality Safety, Health and Environment TPM TPM Introduction World Class Manufacturing

Getting to Level 3 of Total Productive Maintenance will require a LOT OF hard work, but it’s doable. Listed below is a 20-Step process on how to get there, steps 1-12 are part of Level 1 (Excellent Factory), steps 13-17 – Level 2 (Excellent Supply Chain) and finally, steps 18-20…

Read More »Planned Maintenance Pillar Workshop

Planned Maintenance – Introduction General: Provide an overall understanding of Planned MaintenanceFacilitate the site in developing and refining the PM planIdentification of additional training requirements Develop an understanding of: Objectives of the Planned Maintenance PillarThe support required for Autonomous Maintenance, T&E, and EM PillarsThe objectives and approach of each of…

Read More »