Planned Maintenance

Autonomous Maintenance 1st step – 3rd step

F-TAG (Tagging) • F-Tag should be attached to the following malfunctions: Wear, Play, Slackness Leakage Dust, Dirt Corrosion Adherence of raw materials, Deformation, Surface damage, Cracking Overheating, Vibration, Noise … Examples of “Fuguai” – Potential problems Categories of Fuguai Examples Examples of check point 1. Minor defects Dirtiness Scratches Play…

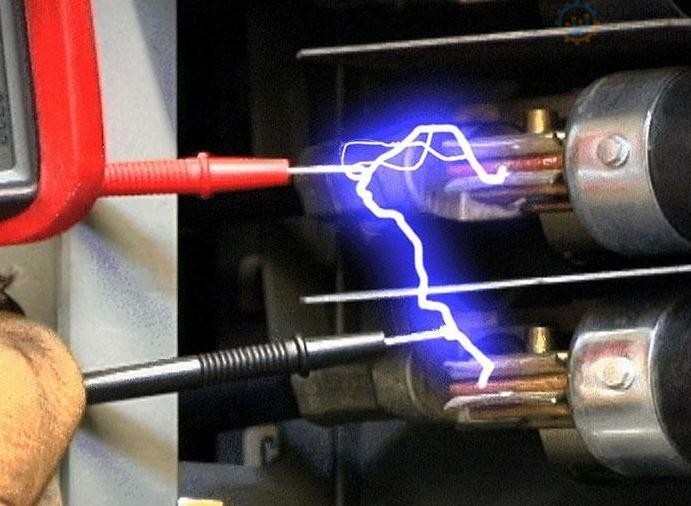

Read More »Electrical Arc Flash Hazards ‘Awareness’ Training

Electrical Arc Flash Safety Every year many workers are treated in hospitals with major injuries related to the arch flash. The flash is instantaneous, the effects of it can last forever and be very traumatizing. What is an Arc Flash? “…a dangerous condition associated with the release of energy caused by an…

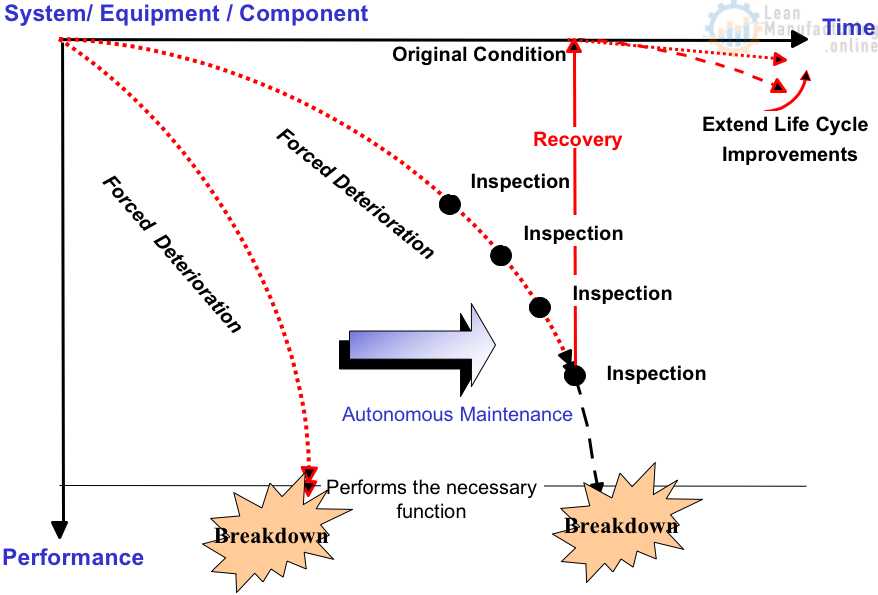

Read More »Approaching Zero Breakdowns by advancing Breakdown analysis

What is Maintenance? Maintenance: It is a set of developed, organized and administered activities with the aim to economically viable ensure the operational status of a specific system. The 7 steps concept of Autonomous Maintenance (operators) are similar to 7 steps of Planned (Effective) Maintenance (trades): “the left and right hand…

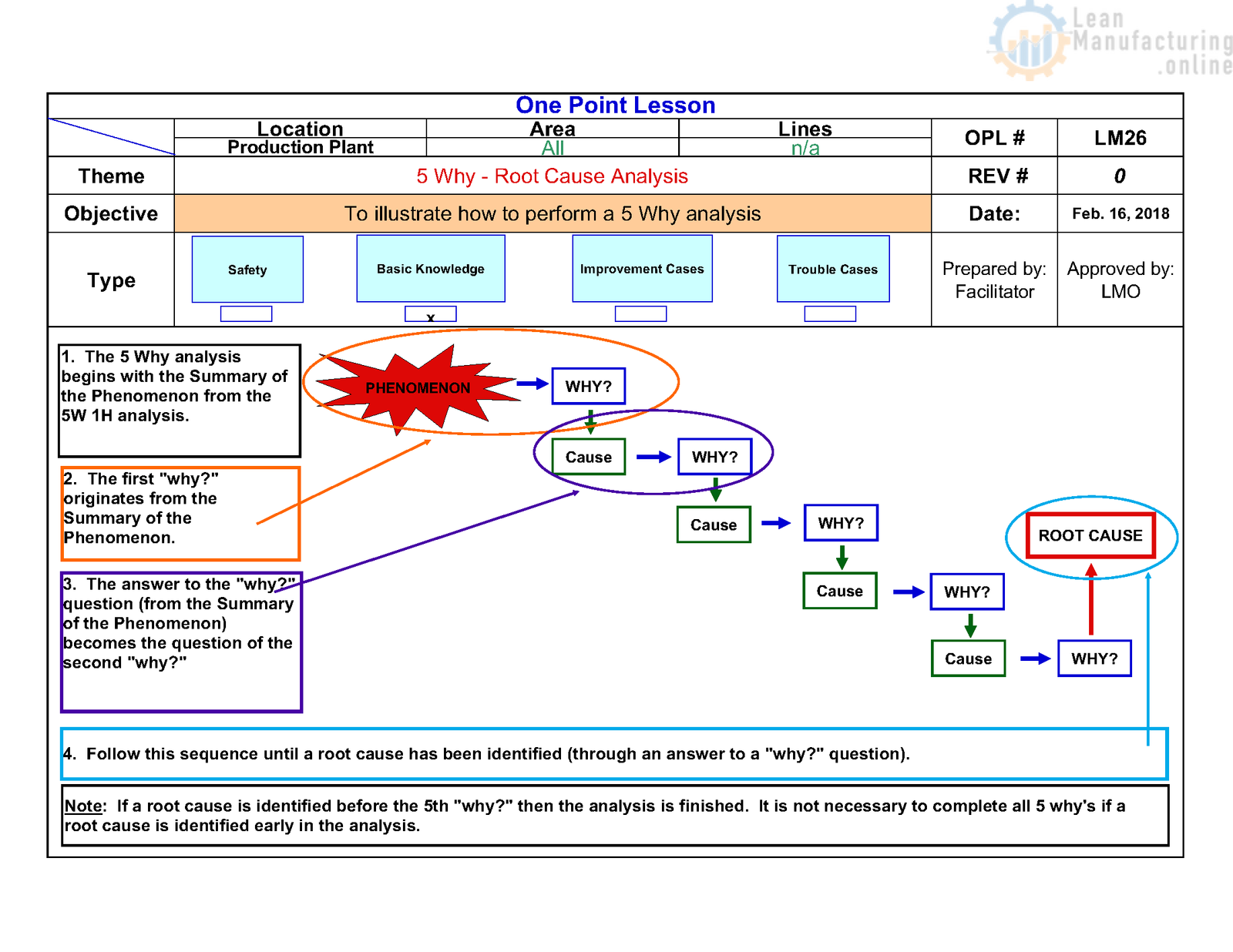

Read More »5 Why Root Cause Analysis (RCA) – One Point Lesson (OPL)

5 WHY Analysis is the key tool used to determine ROOT CAUSES for the Phenomenon identified in theCHECK Phase of CAP-Do. The 5 Why analysis begins with the Summary of the Phenomenon from the 5W 1H analysis. The first “why?” originates from the Summary of the Phenomenon. The answer to…

Read More »