Planned Maintenance

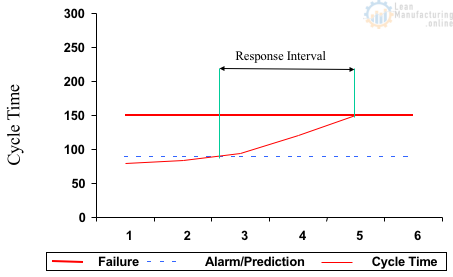

Condition Based Maintenance

PM Element 4. Equipment Maintenance Strategy The same prioritization applied to identify A, B, and C equipment for Time Based Maintenance is applied here to identify the critical equipment. Using CBM for other equipment is also possible based on the factory’s needs. For instance, it is possible to apply Vibration analysis…

Read More »Time Based Maintenance

PM Element 3. Equipment Maintenance Strategy How to start the Time Based Maintenance System? The best way to start is to put more resources into the critical equipment or the most important equipment. How do you define the critical equipment? A way to do that is to establish criteria to…

Read More »Support to Autonomous Maintenance

PM Element 1. Indicators The measurement of the maintenance department is essential because this will help operators and tradesmen to visualize problems in the equipment, prioritize activities, and control the progress. At the beginning of TPM, these Indicators are necessary. Breakdown Breakdown means any unexpected stoppage equals 10 minutes or…

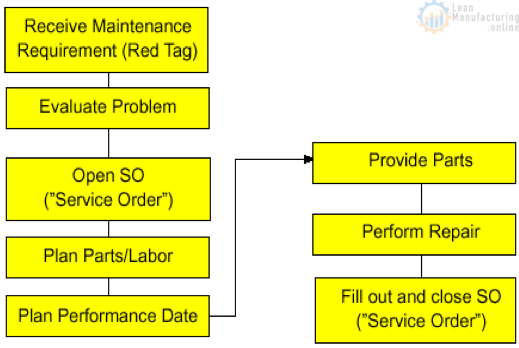

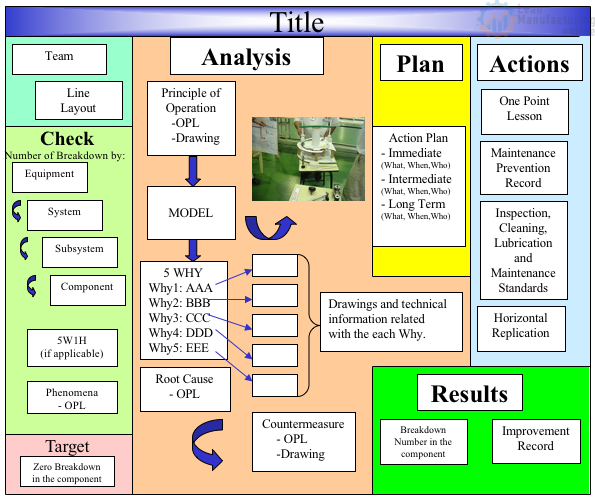

Read More »Zero Breakdown Activities

PM Element 2. Zero Breakdown Activities The biggest challenge during the TPM implementation is to change the tradesmen’s mindset from the reactive approach (firefighters) to a proactive approach (machine physicians). The first step is to explain that a repair does not finish when they fix the machine, but it ends…

Read More »