Safety, Health and Environment

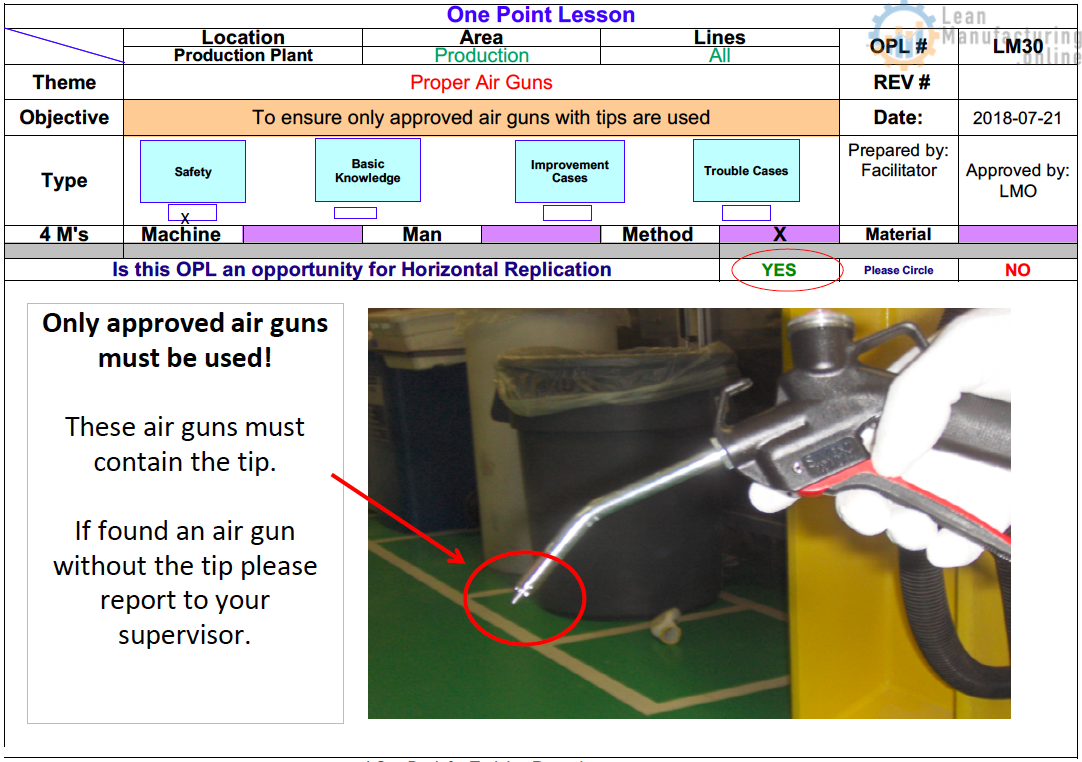

One Point Lesson – OPL – Compressed Air Safety – Usage of restricted air guns for cleaning activities

Usage of compressed air is very effective, however is very dangerous if not handled properly. Recommended to use air with restricting nozzle, reduces safety risk without loosing cleaning effectiveness. All approved air guns must have safety tip, if during pre-operational inspection found that air gun is missing nozzle, please report…

Read More »Fire Safety & Fire Extinguisher Training Module

Introduction This training module is designed for use by Safety Department when training and retraining staff about fire safety and fire extinguisher use. It is important to remember that all fires are dangerous and can grow in size rapidly, and become out of control. Characteristics of Fire Fire is a…

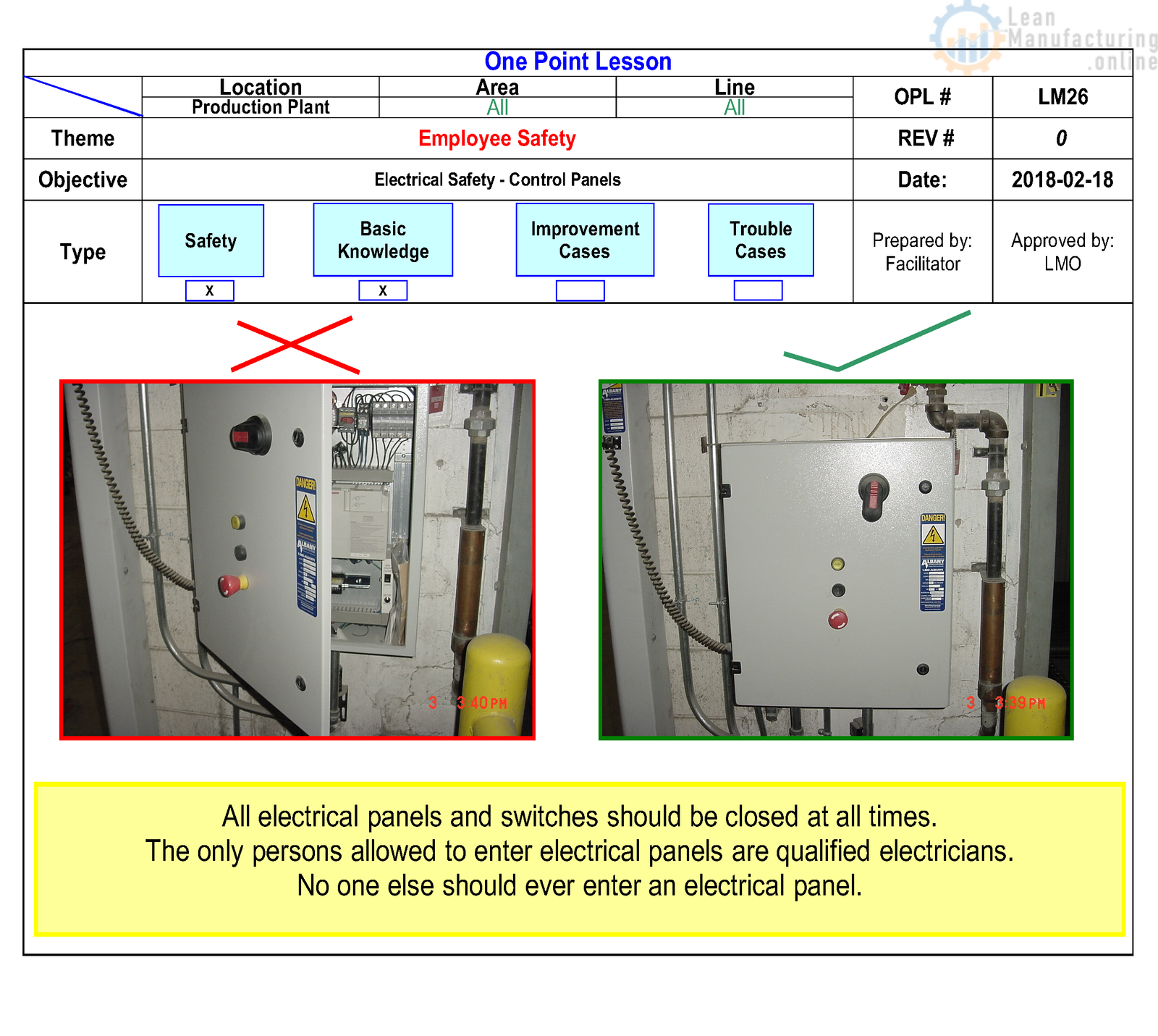

Read More »Electrical Safety One Point Lesson – Electrical Panels

All electrical panels and switches should be closed at all times. The only persons allowed to enter electrical panels are qualified electricians. No one else should ever enter an electrical panel. This OPL is only for reference – always follow safety rules prescribed by your local H&S department.

Read More »Chapter 11. Safety, Health and Environment. Part 3

Zero trapping or catching 1 Definition: A body part getting crushed, twisted, etc. by being trapped between objects 2 In broad terms, there are two types of trapping incident: – Caused by own actions, e.g. operator gets hand trapped when trying to wipe dirt off a moving roller. -Caused by…

Read More »