Training

Troubleshooting packaging and processing equipment

One of the important tasks of Maintenance crew is quickly return equipment back to production after breakdown happens, so minor won’t become major one. Although analyzing breakdown and implementing countermeasures are necessary steps to improve OEE but also to have the best skill set to troubleshoot and repair is essential to…

Read More »Broken Parts Museum – Analyzing and Preventing Breakdowns due to Forced Deterioration

5 Why Analysis Autonomous Maintenance Blog OPL Root Cause Analysis Training World Class Manufacturing

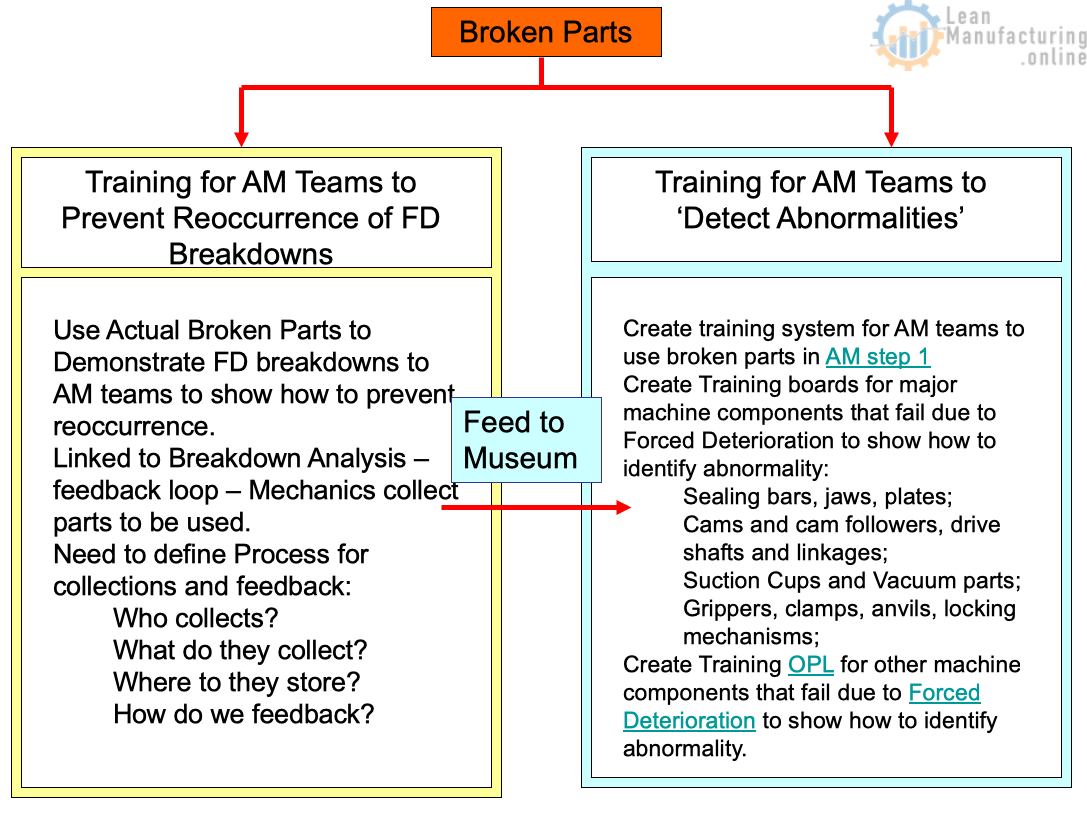

Collecting broken or worn machine parts for later analysis will help to understand root cause of failures, as well as can assist with training AM team members. Training for AM Teams to Prevent Reoccurrence of Forced Deterioration Breakdowns Use Actual Broken Parts to Demonstrate FD breakdowns to AM teams to…

Read More »Workplace Electrical Safety – PM training

The Basics Electricity flows more easily through some materials than others. Conductor – substances that offer little resistance (metal, earth surface) Insulator – Substances that slow down or stop flow of electricity (glass, porcelain, wood) When a person receives an electrical shock, sometimes the electrical stimulation causes the muscles to…

Read More »Global Food Safety Initiative – Preparation for FSSC 22000. Part 3. Food Safety Management Systems Interpretation training

ISO 22000; CLAUSE 4 Food safety management system 4.1 General Requirements This clause is about documenting and maintaining an effective food safety management system, and updating it when necessary. The organization shall a) ensure that food safety hazards that may be reasonably expected to occur in relation to products within…

Read More »