Defect per unit or DPU, is the average number of defects observed in a population sample. Calculated by dividing the total number of observed defects by the total number of units in the sample:

DPU=(Total number of defects)/(Total units)

Defects per opportunity (opportunity must be a real number, so it won’t affect your quality score) or DPO, is total number of possible errors or defects that could be counted in a process or service:

DPO=(Total Number of Defects Observed)/(Number of Units x Number of Opportunities per Unit)

Defects per Million Opportunities or DPMO, is DPO times million and it takes into consideration the number of opportunities within a part or process. By determining the DPMO, you can then assign the sigma level of the process.

Sigma Values

Sigma values are a metric common to Six Sigma (6σ) organizations and provide a baseline for process performance, also 6σ values can be used to compare products, departments, processes – a “benchmark”.

Once you have the DPMO calculated, you can acquire the Sigma values by looking them up on published tables.

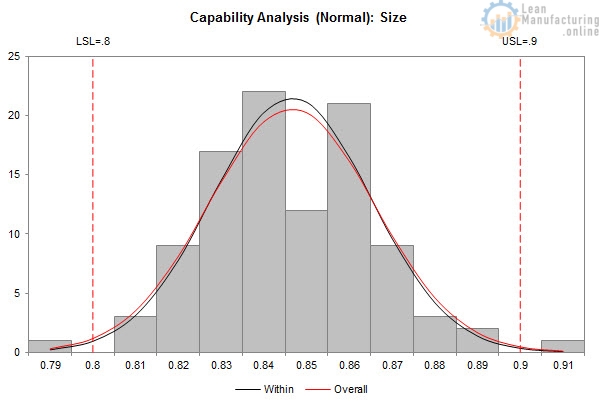

Example of Capability Analysis