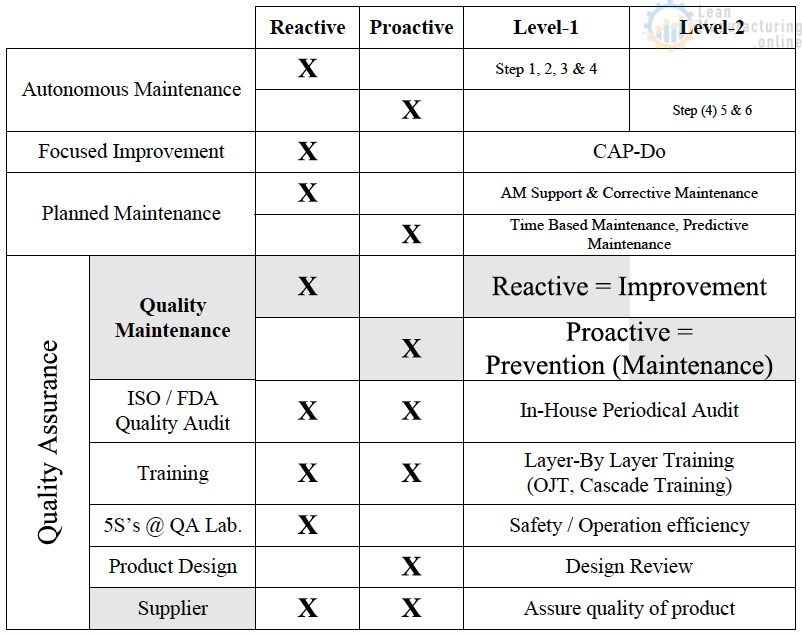

Quality Pillar Roadmap

QA Design Deployment

Quality Maintenance (Hinshitsu-Hozen)

is activities “to set equipment conditions that preclude quality defects, based on the basic concept of maintaining perfect equipment to maintain perfect quality of processed goods and products. The conditions are checked and measured in time-series to verify that measured values are within standard values to prevent defects. The transition of measured values is watched to predict possibilities of defects occurring and to take countermeasures beforehand.”

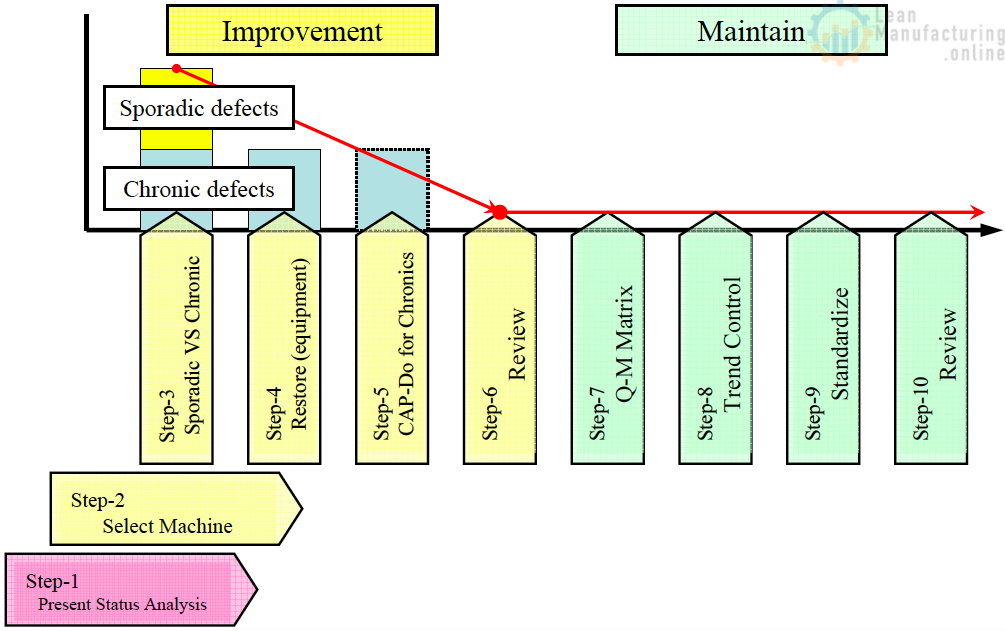

Quality Maintenance Step Deployment

Quality Maintenance Approach

Step-1 Present Status Analysis

Step-2 Select machine

Quality Assurance Matrix

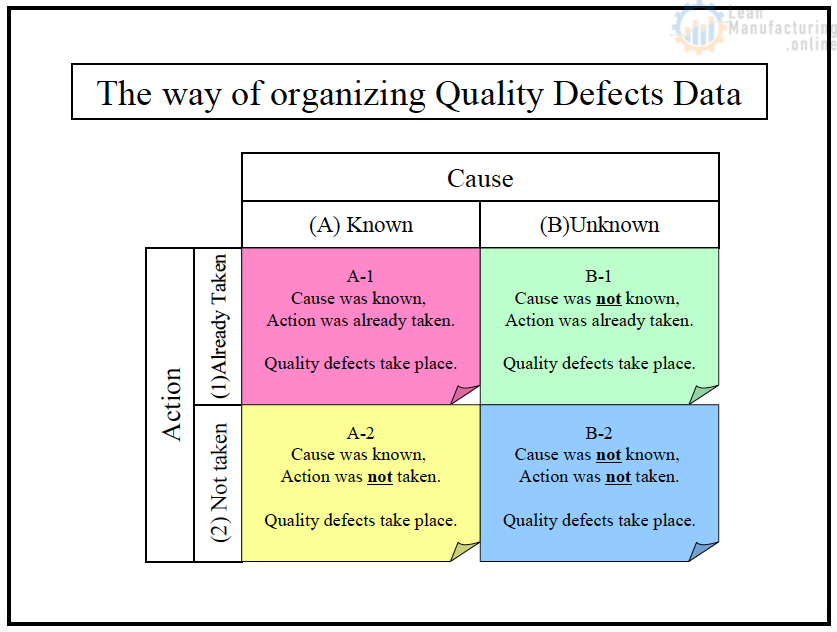

Step-3 Sporadic vs. Chronic Defects

Step-4 Restoration

Step-5 CAP-Do for Chronic losses

Activity Board

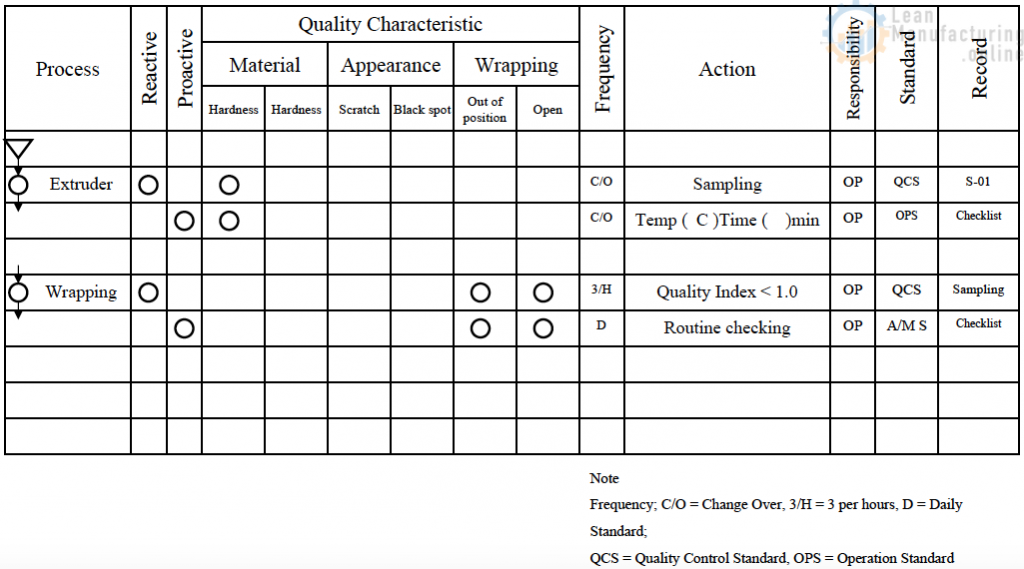

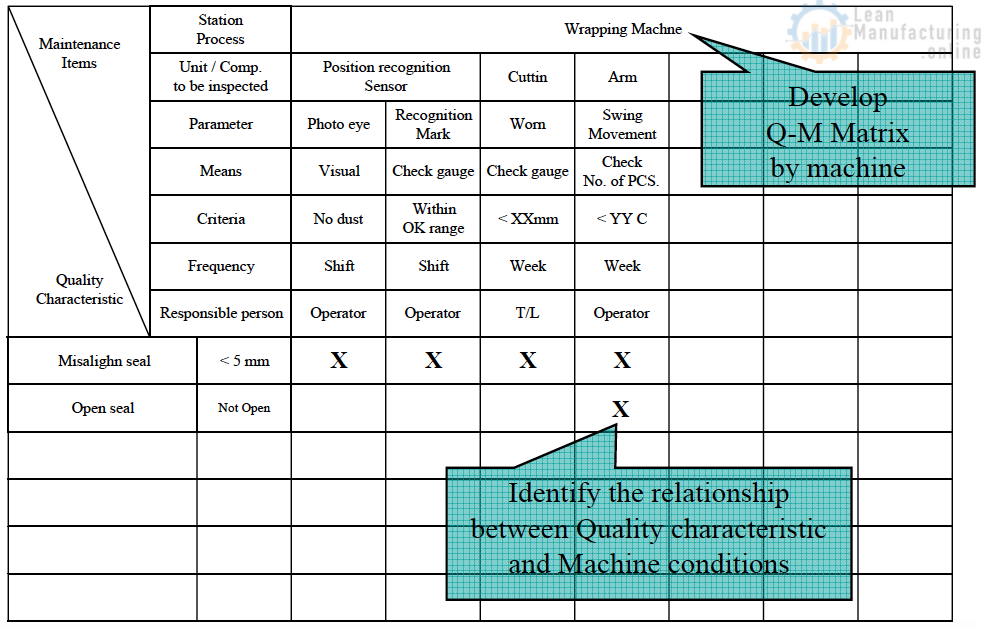

Step-7 Quality Maintenance Matrix

Identify the relationship between Quality Characteristic and Machines Conditions

Example: Quality-Maintenance Matrix

Step-8 Trend Control

- Trend control sheet

- Machine Diagnosis Technology

- X-R control chart

- Cp, CpK Value

- Autonomous Maintenance

- Daily Check sheet

Step-9 Standardization

Step-10 Review