There are several ways to simplify inspections of tensioning devices in manufacturing equipment:

- Use visual inspection methods: Visual inspections are often the simplest and most efficient way to check for proper tensioning. This can include looking for signs of wear or damage and checking for proper alignment and tension.

- Use measuring tools: Tools such as torque wrenches and tension meters can accurately measure the tension on a tensioning device. This can help to ensure that the tension is within the proper range and that the device is functioning correctly.

- Use digital tools: Digital tools such as sensors, cameras, and data loggers can be used to automate the inspection process. This can help to speed up the inspection process and reduce the risk of human error.

- Standardized inspection procedures: Standard procedures for inspecting tensioning devices can help simplify the process by ensuring that all inspections are performed the same way. This can also make it easier to train new employees to perform inspections.

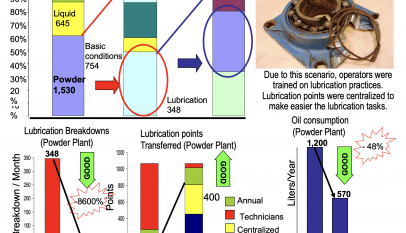

- Regular Maintenance: Regular maintenance of the tensioning devices can help to simplify inspections by reducing the need for frequent checks. This can include lubrication, cleaning, and replacing worn parts.

- Use Checklists: Using checklists can be a helpful tool for simplifying inspections. This can help to ensure that all important items are checked and that nothing is missed during the inspection process.

In this post, we will focus on the visual inspection method

Visual Control is a system by which the critical items within a machine are identified, the optimum operating position established and then marked so that any deviation from the optimum position will be quickly and easily identified.

Maintaining proper tension is important in any chain drive’s adequate performance and life cycle.

As chains wear, they stretch, which results in a wobble and increased vibration. This puts excessive shock into the drive and increases bearing wear, which leads to forced deterioration.

Tensioners or idlers can experience the following issues:

- Too much tension in a drive causes excessive chain and bearing wear.

- Too little tension in a drive allows chain vibration, resulting in loss of power and additional wear.

Our next example shows a typical device for maintaining chain tension with the chain operating limits indicated behind. It creates a simple visual inspection point and, if combined with either clear polycarbonate or steel mesh guarding (discussed a few weeks ago), will deliver a fast decision on whether the tension of the chain is acceptable or action is required.