SMED (Single Minute Exchange of Die) this is a set of techniques that make it possible to improve changeover performance and increase OEE.

- Objectives:

- Reduced downtime

- Increased flexibility

- Improved set-up time

- Goal:

- 75% reduction in set-up with relatively little capital

- Is not about:

- People reduction

Set-up Time Definition

- Set-up Time: the total amount of time to change over equipment or prepare during which the process is down

- Unproductive downtime in manufacturing

- Waiting time in a service setting

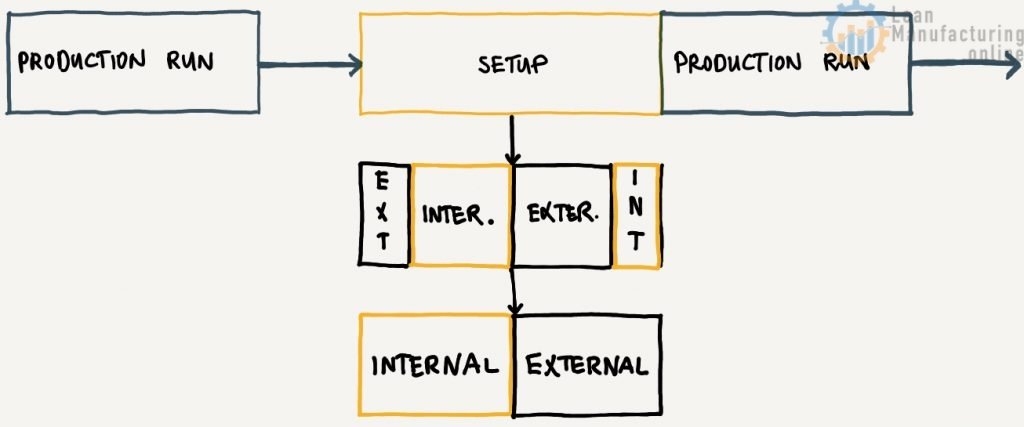

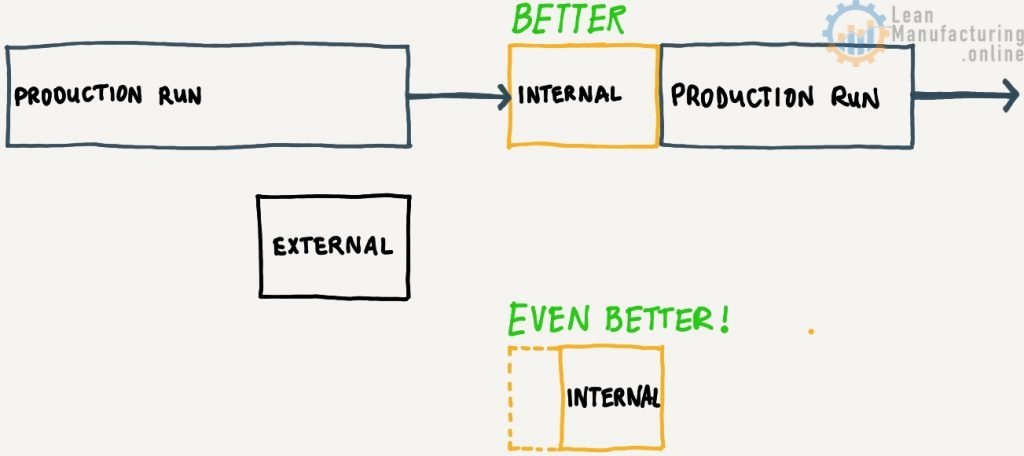

Internal vs External Time

- Internal setup activities are those that can only occur while the process is off-line or stopped

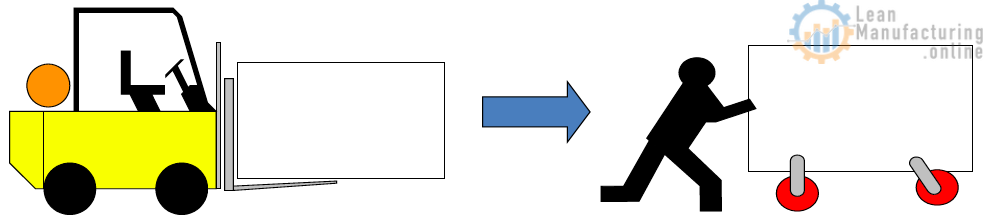

- External setup activities are those we can do before the process has to stop (prepared ahead of time)

SMED Format templates are available here

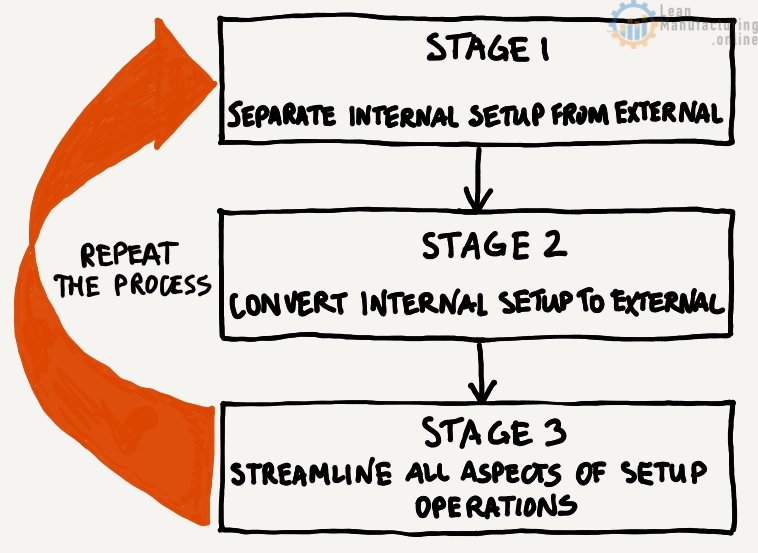

SMED Methodology

Current Process

Stage 1. Separate Internal from External

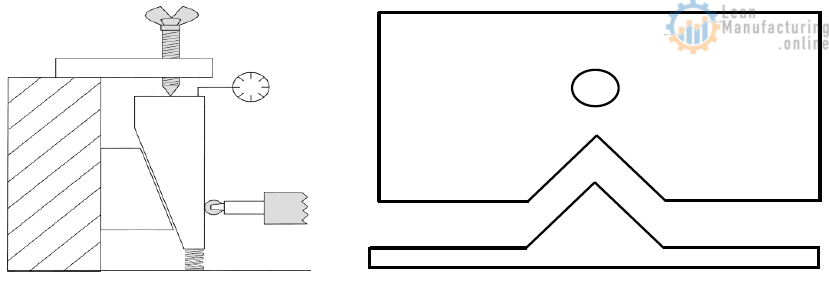

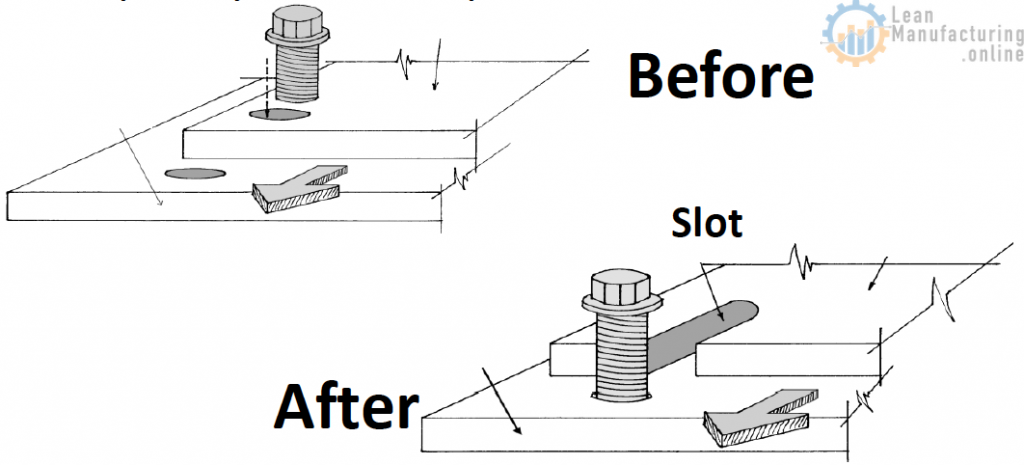

Stage 2. Convert internal set-up to external set-up

Stage 3. Streamline Operations

Study equipment and jigs

- Reduce the need for “fine-tuning” or adjusting wherever possible

- Reduce complexity wherever possible

- Keep all necessary tools and materials at the point of use

- Automate cautiously

- Automate only as a last resort and only if cost effective

- Shigeo Shingo’s Rule of Thumb: automate only when set-up time is less than 3 minutes

- Standardize

- SOPs that reflects the improved set-up time

- Standardize tools, fixtures, clamps, etc.

- Understanding

- Help people understand the why not just the how

SMED Format templates are available here