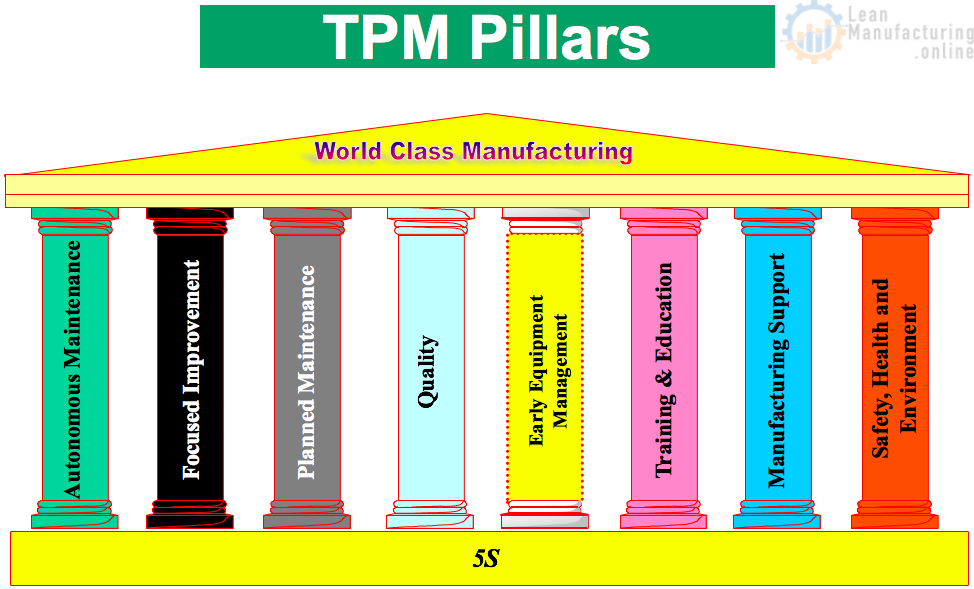

Why a TPM Master Plan Matters

World-class manufacturing doesn’t happen by chance—it’s built on structured systems that bring clarity to every level of operations. The TPM Master Plan serves as the backbone of this journey. It ensures activities are sequenced correctly, responsibilities are clear, and progress is measured consistently. From foundation through awareness, preparation, and expansion, the plan integrates leadership, technical processes, and employee engagement into a single roadmap.

General Activities: Setting the Stage

At the core of TPM are foundational activities that build alignment across the organization. This includes:

- Coaching sessions (JIPM): Guidance to keep TPM aligned with global standards.

- Award process (NMA): Recognition that benchmarks progress against excellence criteria.

- Kick-off and vision setting: Launching TPM with leadership endorsement, organizational structure, and clear KPIs.

- Plans and reviews: Regular updates to track milestones and ensure accountability.

- SHE and quality audits: Integrating safety, health, environment, and quality from the start.

- Factory campaigns: Visible initiatives like safety campaigns, posters, or recognition events that reinforce engagement.

These steps build awareness and ensure everyone—from operators to leaders—understands why TPM matters.

Autonomous Maintenance: Empowering Operators

Autonomous Maintenance (AM) is the heart of TPM. Operators take ownership of equipment care, ensuring reliability through proactive actions:

- Initial cleaning and inspection (Step 0–1): Discovering hidden defects and restoring equipment.

- Countermeasure implementation (Step 2–3): Correcting issues at the source.

- Standardization (Step 4–5): Embedding best practices into visual controls and daily checks.

- Full operator responsibility (Step 6–7): Operators manage routine care while focusing on prevention.

This structured journey not only improves equipment health but also builds operator skill and pride in ownership.

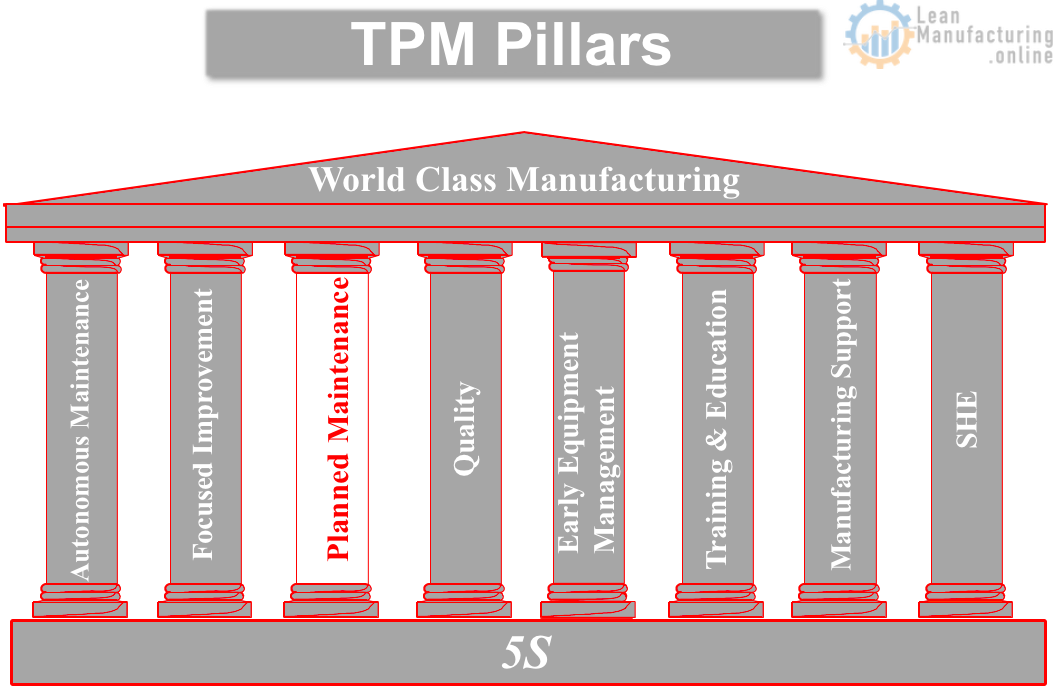

Planned Maintenance: Reliability at Scale

While operators focus on daily care, Planned Maintenance (PM) ensures that long-term reliability is not left to chance. Key steps include:

- Criticality assessment: Ranking machines to prioritize resources.

- Breakdown analysis and records: Capturing data to prevent recurrence.

- Spare parts planning and lubrication systems: Standardizing maintenance to avoid unplanned downtime.

- Periodic maintenance scheduling: Integrating preventive, predictive, and corrective tasks.

The PM pillar strengthens reliability, reduces waste, and creates a predictable production environment.

Focused Improvement: Eliminating Losses

Focused Improvement (Kobetsu Kaizen) targets chronic losses that drain efficiency. The TPM Master Plan highlights:

- Loss analysis workshops using tools like Pareto, OEE breakdowns, and value stream mapping.

- Cross-functional teams tasked with specific themes, such as energy reduction or defect elimination.

- Sustainable improvements driven by PDCA cycles, with results integrated into standard work.

By systematically reducing the “hidden factory” of losses, organizations unlock capacity without major capital investment.

Training, Learning & Education: Building Capability

TPM is only as strong as the people who drive it. Training activities span across:

- Skill matrices and gap analysis: Identifying where teams need support.

- Standard training programs: Covering TPM principles, problem-solving, and equipment care.

- Certification and skill upgrades: Ensuring staff are confident in applying TPM methods.

- Annual training plan: A structured calendar that aligns skills with business goals.

This pillar ensures knowledge doesn’t stay in pockets but spreads across the organization.

Quality Maintenance: Zero Defect Mindset

The TPM Master Plan emphasizes defect prevention by strengthening process conditions and equipment precision:

- Defect mapping and control charts: Identifying conditions that lead to defects.

- Inspection standards: Embedding checks into the process, not at the end.

- Root cause analysis: Applying tools like 5 Whys and fishbone diagrams to eliminate systemic errors.

- Customer-first thinking: Shifting quality from inspection to prevention.

By aligning maintenance with quality, organizations ensure that equipment delivers consistent, defect-free output.

SHE: Safety, Health & Environment Integration

SHE isn’t a separate program—it’s embedded within TPM. The plan integrates:

- Risk assessments and safety audits alongside equipment inspections.

- Hazard elimination campaigns that engage employees in preventive thinking.

- Environmental improvement programs, such as waste reduction and energy optimization.

By making SHE part of the daily routine, the TPM culture ensures safe and sustainable growth.

Early Equipment Management: Designing Reliability In

New equipment should never start at “infant mortality” failure levels. Early Equipment Management (EEM) ensures:

- Design reviews with operators and maintainers.

- TPM checklists during procurement.

- Feedback loops from past failures applied to new installations.

This reduces commissioning time, improves startup quality, and ensures equipment is built with maintainability in mind.

Manufacturing Support: Extending TPM Beyond Production

The TPM Master Plan also applies to support functions such as warehouses and logistics. Key activities include:

- Warehouse cycle counting for accurate inventory.

- Administrative support systems for scheduling and tracking.

- Cross-functional problem solving extending TPM tools beyond the shop floor.

This ensures the entire value chain benefits from TPM practices, not just production lines.

From Plan to Culture

The TPM Master Plan is more than a document—it’s a roadmap that connects leadership vision, structured activities, and employee engagement. By following its stages, organizations can move from firefighting to prevention, from isolated improvements to a culture of excellence, and from compliance to pride in world-class performance.

📂 Download the full TPM Master Plan spreadsheet here: https://zbk.li/KRTzl