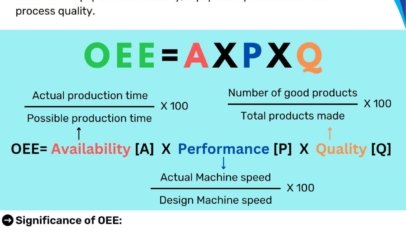

Visual Management helps remove gaps between what does happen and what should happen.

Visual controls are placed directly on the equipment to be controlled to indicate operating conditions, rotation directions and other essential information. Apart from its application in direct plant equipment, it is also an extremely powerful tool for Team communication via activity boards, Team members, Team activities, plant operating performance, graphs etc.

Some examples:

→Mark each item of equipment with its name and number to make everyone aware of important units.

→Put match marks on nuts and bolts to simplify checking for slackness.

→Indicate lubricant levels, types and quantities to improve maintainability.

→Label the covers of devices such as V-belts, chains and couplings with their rotation direction and specifications to improve maintainability and simplify checking.

When to use Visual Management?

Visual controls are essential to ensure consistent performance of cleaning, inspecting and lubricating tasks to make them easy to be performed correctly by any trained individual.