Operators should look after their equipment

Autonomous maintenance aims to create a scenario where all operators look after their equipment, carrying out routine checks, oiling and greasing, replacing parts, doing simple repairs, spotting problems at an early stage, checking precision, and so on.

Operators need to understand their equipment

Autonomous maintenance can only be carried out by operators who are thoroughly conversant with their equipment. An operator’s work does not begin and end with the operation; it also has to embrace maintenance.

The essential skill required of an operator is the ability to identify abnormalities and immediately notice when something is not quite right with the output quality or the equipment. This and the three other abilities operators need are listed below.

Operators need the ability to:

- Recognize abnormalities when they see them (The ability to identify abnormalities)

- Respond swiftly and correctly when abnormalities occur (The ability to take corrective action)

- Set clear criteria defining what is normal and what is not (The ability to set conditions)

- Keep strictly to the rules governing these conditions (The ability to sustain)

More specifically, each operator needs to acquire the ability to:

- Identify and correct equipment abnormalities

- Understand how the equipment works, and identify the causes of any abnormality

- Understand the relationship between the equipment and the quality of the product, foresee quality problems, and find out what is causing them

- Carry out repairs

- Implement appropriate Focused Improvements, either independently or in cooperation with other departments

Operators who satisfy these requirements will feel for the equipment and be sensitive to the subtle early warning signs of defective output or failure. They will be able to discover the causes of problems and forestall them. Then, and only then, they can be called equipment competent.

The Basic Precepts of Autonomous Maintenance

The equipment has become increasingly sophisticated and complex, and the maintenance function has gradually separated from the production function. The result is that production and maintenance departments have become isolated in their camps, with one making and the other fixing. This approach makes equipment much less efficient than it could be. The need to remedy this culture has led to the emergence of the discipline known as “Autonomous Maintenance,” the basic precepts listed below.

The basic precepts of Autonomous Maintenance:

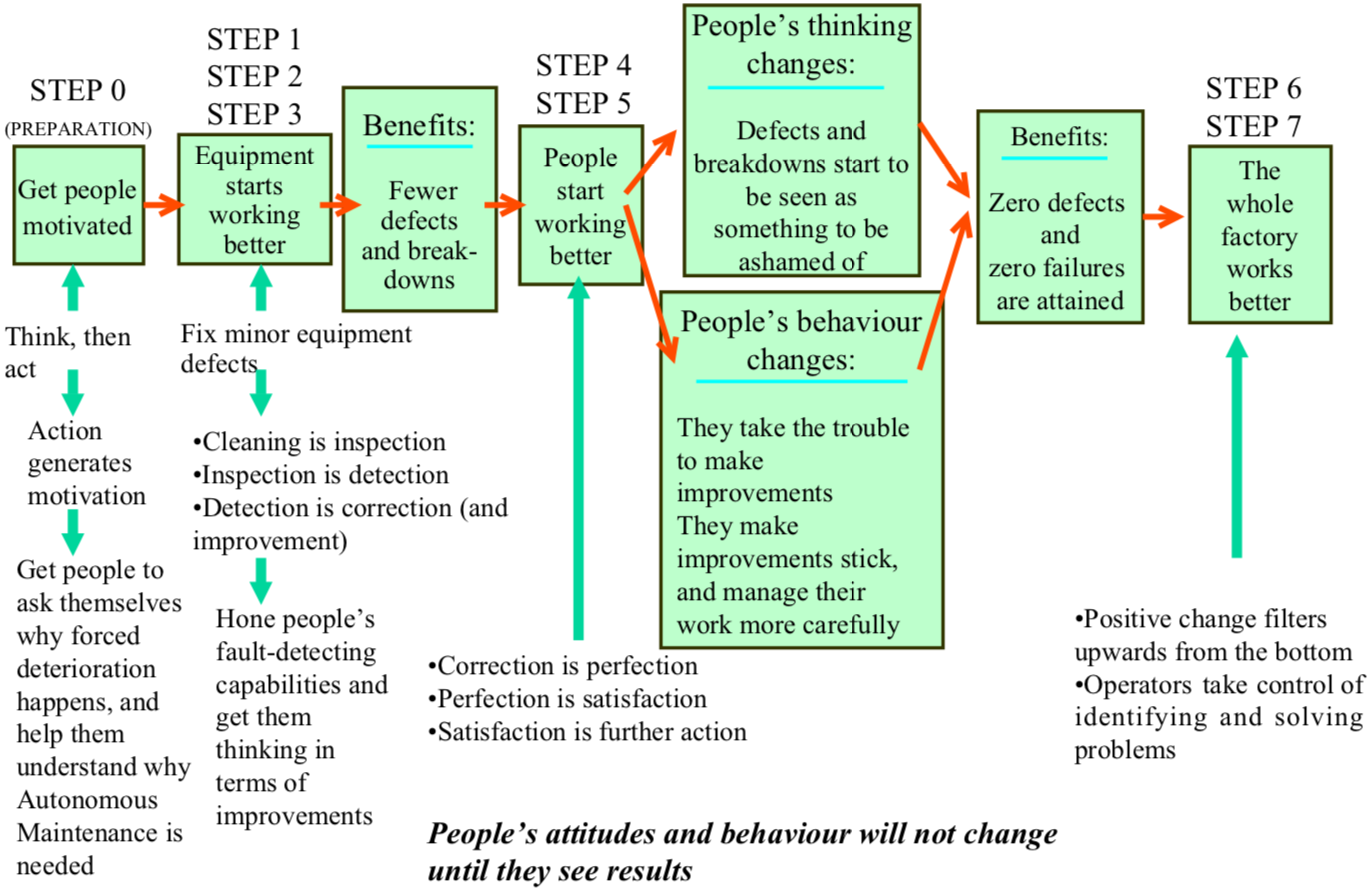

- The problems that stop equipment from working, or make it work less effectively, can be eliminated – in other words, zero-defect, zero-breakdown status can be attained – by changing the way everyone who works with the equipment, including the operators, thinks and behaves.

- When the equipment works better, the people work better, and when the people work better, the whole factory works better.

- Autonomous Maintenance should be introduced step by step under management’s guidance, with each step implemented thoroughly. It should involve the whole workforce and empower individuals to fulfill their potential.

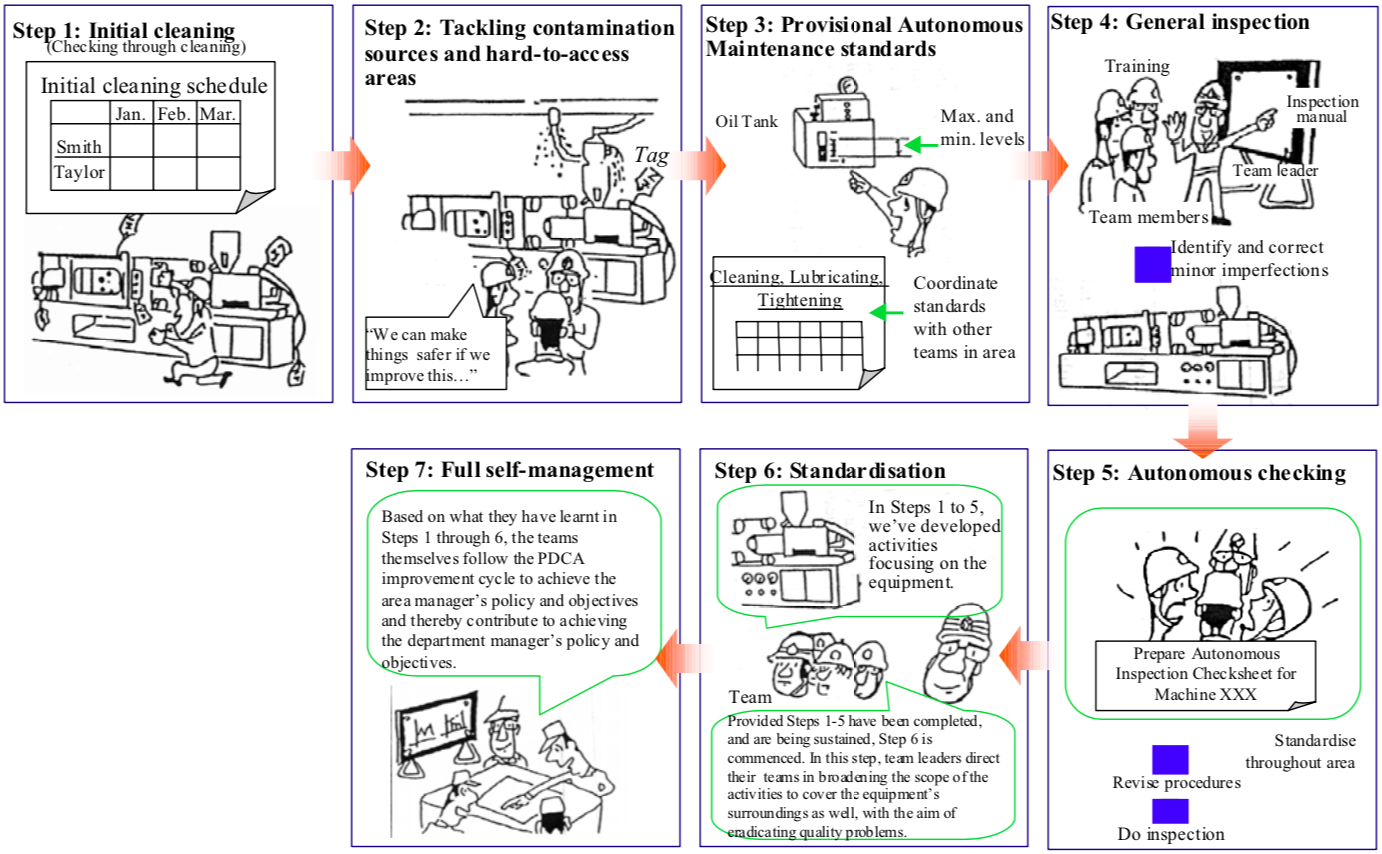

Figure “The Steps to Autonomous Maintenance, and How they Work” illustrates the steps to be followed in rolling out an Autonomous Maintenance program based on these precepts. The individual steps are detailed in Section 2 (‘Step-by-Step Development’).

Because of the situation described above, in which maintenance and production have become separate entities and the ‘I make, you fix’ mentality has permeated the shop floor, many operators see themselves simply as ‘producers,’ whose only contact with the equipment consists of keeping the process supplied with materials and performing quality checks. Anything to do with caring for the equipment, even lubricating it and keeping it clean, is seen as a specialist maintenance caste province. The upshot is that operators disclaim all responsibility for how their equipment is running; if a breakdown occurs, they blame the maintenance technicians for not doing their job correctly or claim that the company has chosen the wrong type of machine – the problem never has anything to do with them.

This way of thinking has to be changed. By persuading operators to do their bit, even if this means tightening up nuts and bolts and cleaning and lubricating the machinery, we can help to prevent equipment from failing. And if operators are encouraged to get in touch with their equipment in this way, they will be able to spot any abnormalities and rectify them promptly.

The Seven Autonomous Maintenance Steps

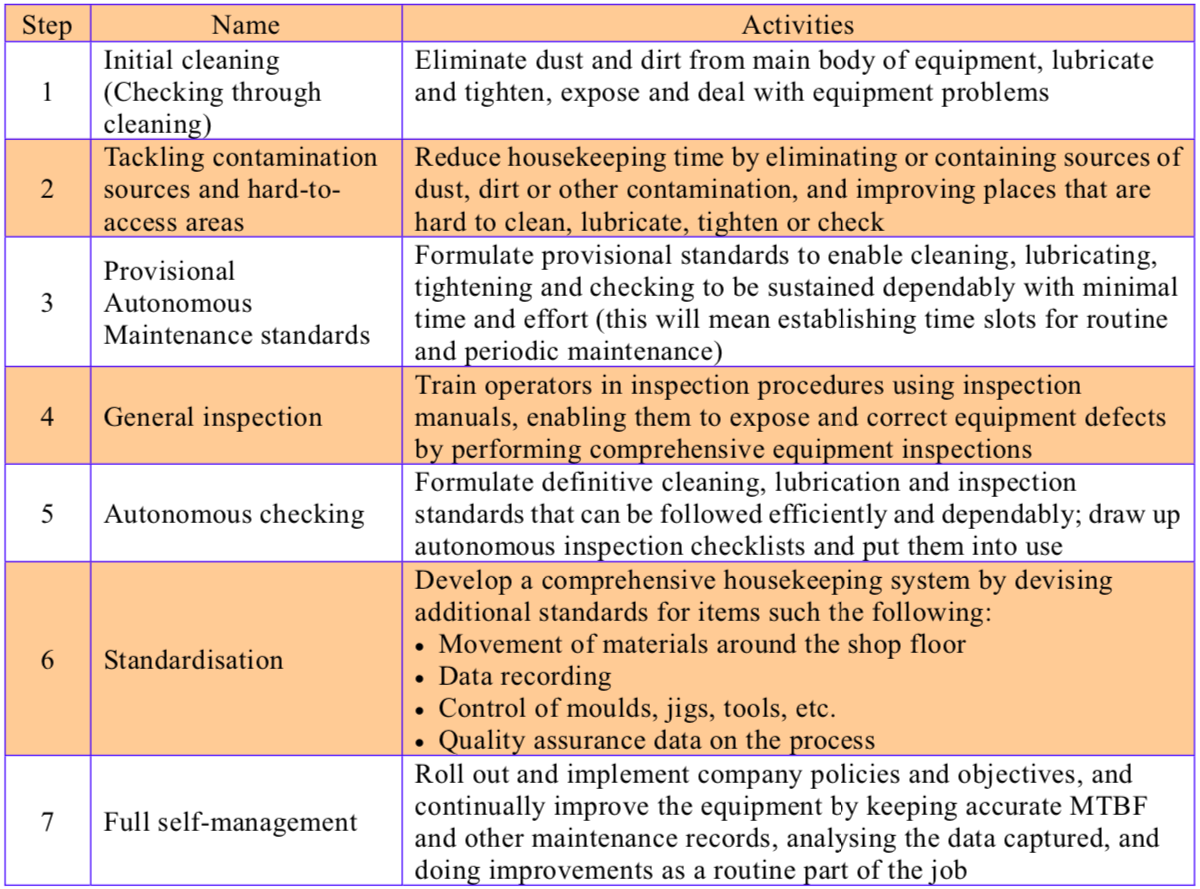

If it is going to work appropriately, Autonomous Maintenance must be implemented by a management-led plan. A system for progressively upgrading production equipment and operators’ capabilities should be put in place (see Table “The Seven Autonomous Maintenance Steps”), and the Autonomous Maintenance program should be rolled out following this plan, with each step being reviewed by management before an authorization is given to proceed to the next.

The Three Stages of Autonomous Maintenance

The seven steps for developing Autonomous Maintenance can be grouped into the three stages described below:

Stage 1

Steps 1 to 3 constitute Stage 1. This is where the primary equipment conditions are painstakingly achieved (mainly through cleaning and inspecting), and a system for sustaining these conditions is established.

Everyone should be helped to understand the process that will transform their equipment as they implement Autonomous Maintenance. They need to discover truths like the following:

- “Cleaning is inspection” (cleaning should not just be cleaning for its own sake, but ‘cleaning with the meaning’; i.e. cleaning to find problems);

- “Inspection is detection” (careful inspection of the equipment while cleaning it will reveal all kinds of imperfections);

- “Detection is correction” (discovering a problem motivates correcting it and making further improvements).

During this process, everyone needs to get into the habit of working through difficulties, exercising creativity and ingenuity in solving problems, and thinking hard about what they are doing and why they are doing it. The work carried out at this stage will revolve around three activities: cleaning, lubricating, and tightening. These activities, through which basic equipment conditions are sustained, are the minimum prerequisites for preventing equipment deterioration and form the foundation on which all the other activities are built.

Stage 2

Steps 4 and 5 constitute Stage 2. At this stage, operators receive training in general equipment inspection skills and start performing these inspections for themselves. This enables them to move on from preventing deterioration to measuring deterioration and learn that:

- “Correction is perfection” (reversing deterioration and making improvements brings good results);

- “Perfection is satisfaction” (getting good results gives a feeling of accomplishment);

- “Satisfaction is further action” (a feeling of accomplishment makes people want to achieve even more).

Through this, the operators become truly equipment-competent, capable of performing routine checks using their five senses backed up by logic, and able and willing to improve their initiative. This is the stage at which the results appear, and people’s attitudes change. These new attitudes produce a unique atmosphere, as operators begin to take pride in the smooth running of their equipment, while defects and breakdowns are seen as letting the side down. This is a crucial part of creating a proper system of self-management.

Stage 3

This stage consists of Steps 6 and 7. This is the stage at which the finishing touches are put to the Autonomous Maintenance program by completing the process of standardization and self-management begun in the previous steps, and operators work towards perfecting their maintenance skills. The key strategies here are as follows:

- Improving workplace management techniques, expanding the scope of self-management, heightening goal consciousness, instilling an awareness of maintenance and other costs, and training operators to handle minor equipment repairs.

These processes transform the operators and the workplace, and self-management kicks in.