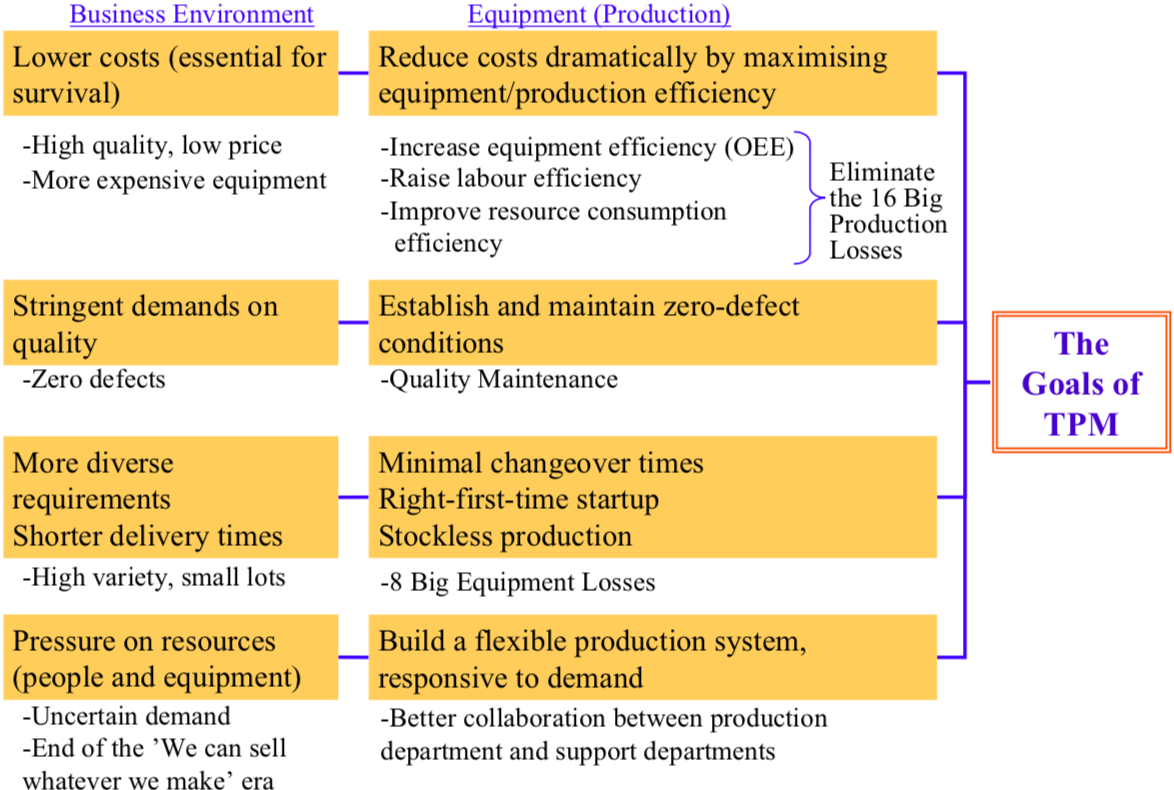

There are some very cogent reasons why companies need TPM now, namely:

- The business environment has become increasingly unforgiving, and companies must eliminate all forms of waste to survive. They can no longer get away with allowing expensive equipment to break down.

- The quality demands are more exacting than ever, and even a single defective item in a batch is no longer permissible. Companies are now expected to guarantee the quality of every single item they deliver.

- The diversification of consumer requirements has increased the demand for high-variety, small-lot production, and shorter delivery times. This has made businesses keenly aware of the need to eliminate the 8 Big Equipment Losses, and of the effectiveness of TPM as a survival strategy.

- Companies can no longer beat off the competition purely by making their production operations more efficient. At one time, they could sell whatever they made. Now, they have to take only what they can sell. This means that, as explained in Table “TPM – A Conceptual Guide”, in addition to eliminating the 16 Big Losses relating to equipment, resource consumption, and human labor, they must also generate profits by strengthening (and improving collaboration among) all of the departments concerned with any of the processes involved in planning and developing the product, manufacturing it, and delivering it to the customer – including product planning, research, development, design, technology, purchasing, sales, and distribution, as well as the production department itself.

Businesses know they need a new type of TPM if they want to stay on the map.