AM Step 1 Objectives

Machine Reliability:

- Prevent Forced Deterioration

- Restore Latent Defects in Equipment

- Identify Source of Contaminants

Skill Up:

Understand machine Structures & Function

Activity – Go to the Genba (Actual Place!):

1. Deep Cleaning

2. Discover Potential Problems Fuguai

3. Tagging

4. Tentative Action for SOC

5. Routine Cleaning Stds

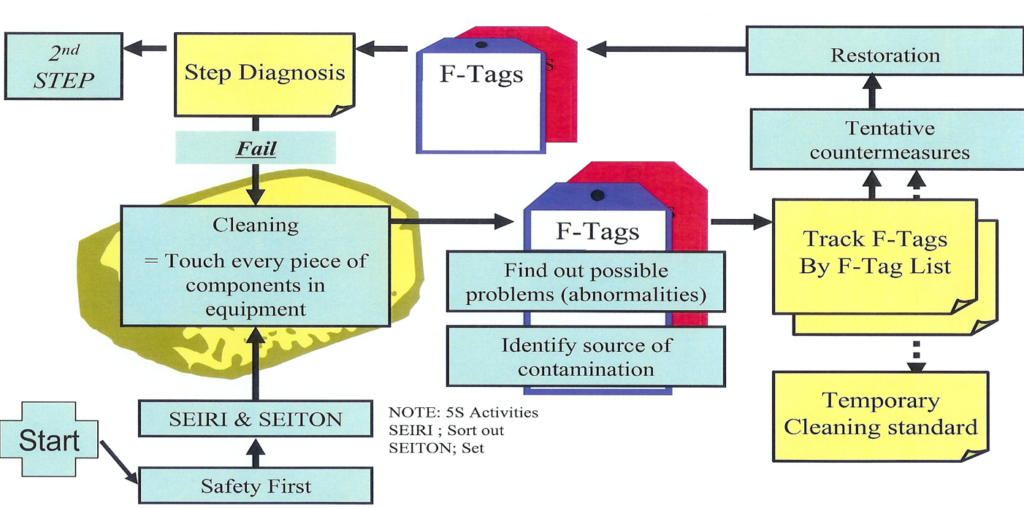

AM Step 1 Flow (Don’t forget SAFETY FIRST!):

Zero Energy State (ZES) or Lock Out & Tag Out (LOTO)

Follow proper LOTO OPL’s to effectively isolate all energy sources on equipment to be worked on

- PPE: Wear proper Personal Protective Equipment

- SOE: Know your Sources of Energy

- LOTO: Lock your equipment out properly

5S Activities – SEIRI & SEITON (Sort out and Set)

- Perform the SORT activity of 5S

- Create the “Red Tag Zone” for those items you do not need

AM Step 1 – STORE (SET)

- Perform the STORE (SET) activity of 5S

- Store everyday items in a convenient location — where it is needed

- Store ONCE IN A WHILE items out of the way, but in a known, logical location

- Use pictures, labels, colors, tape, paint, OPLs, etc. to standardize the STORE location

AM Step 1- Initial Clean Cleaning With Meaning!

- Clean to Inspect (Look for Fuguai)

- Inspect to Detect (ID SOC & HTA)

- Detect to Correct

- Correct to Perfect

Perfection is Satisfaction!

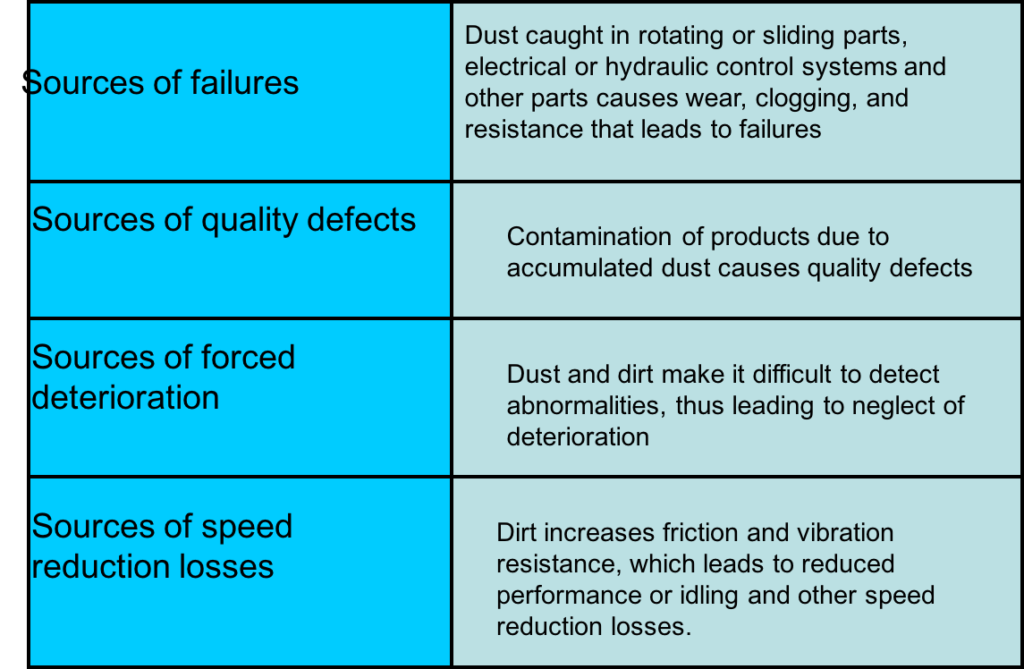

Problems caused by insufficient cleaning

What is “Fuguai“? Fuguai = Problem or Abnormality

- functional defects

- pollution

- difficult to access/observe

- hard to tend/serve

- unsafe

Where Do You Find “Fuguai“?

Small Parts:

- nuts and bolts, screws

- chains, links, pulleys, buffers

- springs, spanners, cylinders

- piping and related parts

- valves, gaskets, controls, filters

- couplings, bearings, shaft

- switches, sensors

- cabling and related parts

- indicators, monitors, screens

- guards, doors, windows

- emergency switches, safety devices…

Biggest Parts:

- main equipment

- operate system

- moving and turning parts

- transport systems

- hydraulic system

- compressed air system

- storage system

- cool/heating system

- instrumentation and controls

What Malfunctions are “Fuguai“?

- Wear, Play, Slackness

- Leakage, Spills

- Dust, Dirt, Contamination, Corrosion

- Deformation, Surface Damage

- Cracking, Overheating

- Vibration, Noise

- Safety Hazards

How to Discover “Fuguai“?

Use your 5 senses:

- SEE –> use your eyes to observe

- HEAR –> listen and try to hear the unusual noises

- SMELL –> try to discover strange smells

- TOUCH –> try to feel heat, vibrations

- TASTE –> not normally recommended, but can be done from time to time

Use your brain: think before you make a judgment

How to find “Fuguai” During Initial Clean?

- 1st step: OBSERVATION

Before doing anything, first, observe the machine as a whole to find all visible defects

- 2nd step: CLEANING (1st phase)

Clean the machine thoroughly such that all hidden defects will be uncovered

- 3rd step: DISASSEMBLING PARTLY

disassemble the main components of the machine and if possible, find the visible defects as done with step 1

- 4th step: CLEANING (2nd phase)

Clean parts and components that can be accessed after disassembly

- 5th step: ASSEMBLING

OBSERVATION:

- Before you wipe and clean anything…

- TAKE A GOOD LOOK AROUND!

- You don’t want to miss potential FUGUAI !!! (Example loose fastener on the floor)

CLEANING (1st Phase)

- Next, perform a deep clean on the main body of the equipment, touching every component of the machine to discover hidden FUGUAI. (Example found worn chain guide)

DISASSEMBLE PARTLY

Now that the main body is clean, Start disassembling the sub-components of the equipment to discover even more hidden Fuguai.

Now that the main body is clean, Start disassembling the sub-components of the equipment to discover even more hidden Fuguai.- Most of the hidden components of a machine that have never been through AM Step 1 will look like on the picture with dirty machine components.

CLEANING (2nd Phase) & REASSEMBLE

- Once all Fuguai have been identified in the sub-components, clean the area and reassemble when complete.

As mentioned earlier, you will find many Fuguai during the deep cleaning of the equipment! But what is to be done to keep track of all of them?

FUGUAI TAGS, OF COURSE, or simply F-Tags

Collect Evidence (Genbutsu)…

- Broken Parts

- Worn Parts

- Debris, Contaminants…

Save these parts and contaminants as pieces of evidence and treasures of your hard work. (You’ll use them later)

It won’t do much good to just put F-tags on the machine and collect our Fuguai. We must keep track of the progress.

An F-Tag is also a visual work order

“Four Lists” are to be used to track (Simple Excel Spreadsheets can be created):

- Abnormality List

- F – Tag Tally Sheet

- SOC (Sources of Contamination) List

- HTA (Hard-to-Access) List

Also, it’s a good idea to create an F-tag tracking center (board)

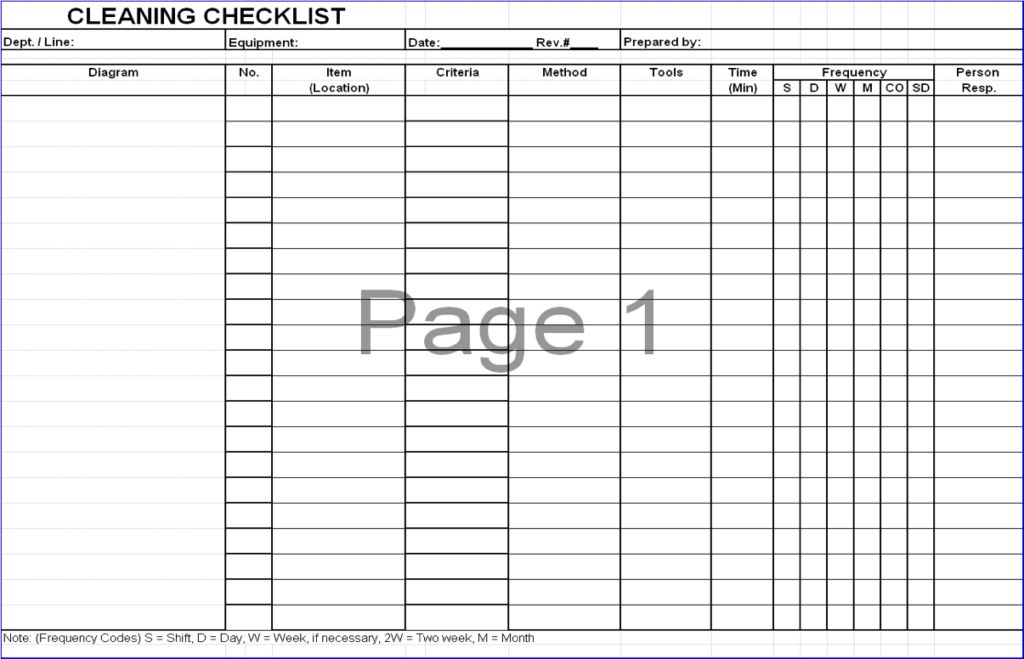

Tentative Cleaning Standard

Tentative Countermeasures are extremely important!!!

Not only do they help reduce cleaning time the second time around, they help reduce forced deterioration.

Re-Tagging

- Were the “Fixes” effective?

- In this step, we may need to “Re-Tag” to ensure the abnormality has been successfully eliminated

- Think of this as the “Verify” step

AM STEP 1 CHECKLIST

Auditing Process: Line Team performs self-audit. If they pass with a score of 80% or more, then the management team performs an audit. If the line passes with a score of 80% or more, the line/equipment moves to the next AM Step.