Define-Measure-Analyze-Improve-Control is a formal problem-solving process, and a major tool of Lean Six Sigma, based on formula Y= f(X), metric that measures the problem.

Define

The first step is to identify a problem. Lean six sigma approach utilizes Y=f(X), a function that defines one variable in terms of another. The statement “y is a function of x” (denoted y = y(x)) means that y varies according to whatever value x takes on.

Example: Quality=f(Process control, Raw material, Equipment etc.)

- Cost of Poor Quality

- Critical To matrix

- Pareto Chart

- SIPOC

- Voice of the customer

- Kano Analysis

- Survey Design

Measure

Capture data on the Y metric (if not already available in Define) and “Potentials X’s” that we believe could impact the Y.

- SIPOC

- Stakeholder analysis

- Spaghetti chart

- Check Sheet

- SS Analysis

- Process Capability Analysis

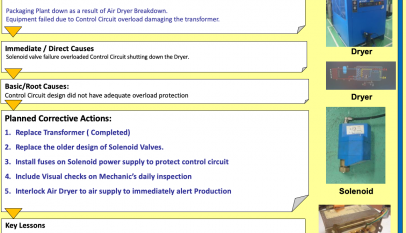

Analyze

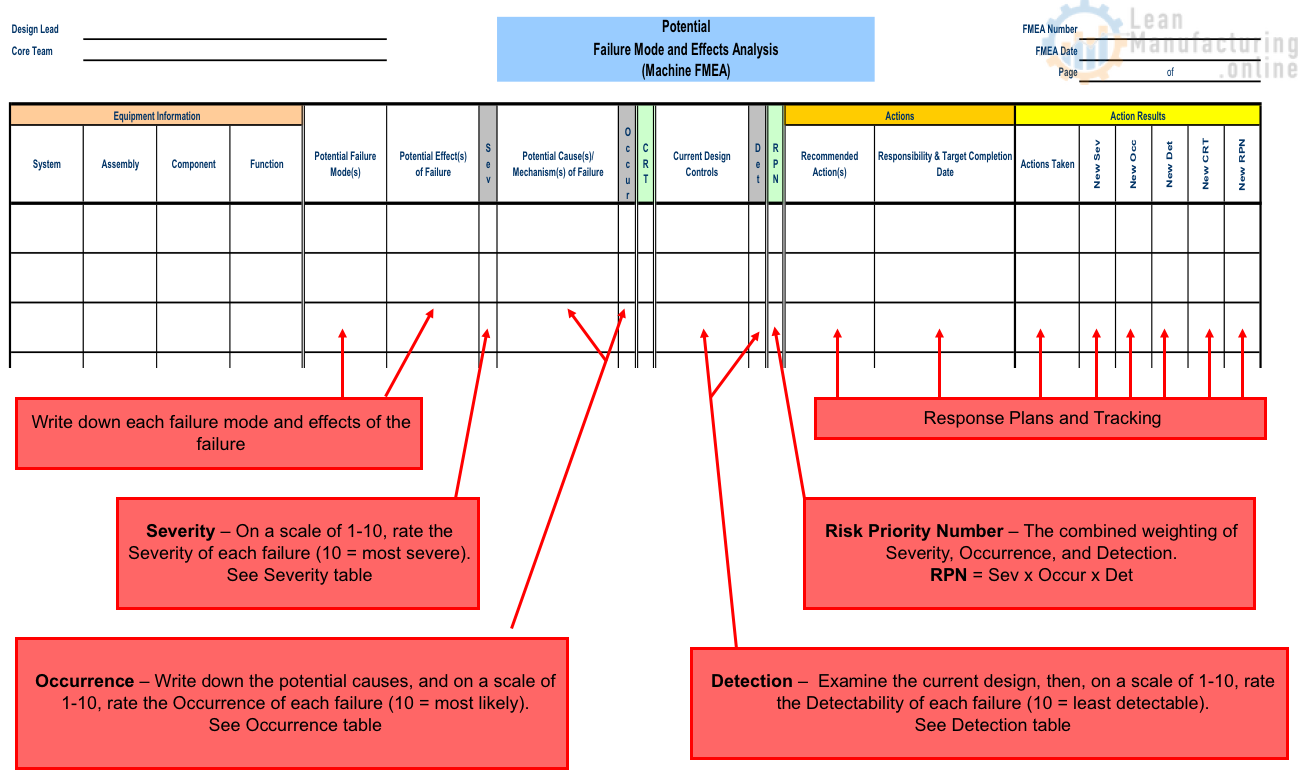

Through your process, the graphical and statistical analysis identifies the “Critical X’s” (or Root Causes) that truly impact the Y.

- Ishikawa diagram

- Cause and Effect Matrix

- Failure Mode and Effects Analysis (FMEA)

- Correlation and Regression

- Hypothesis testing

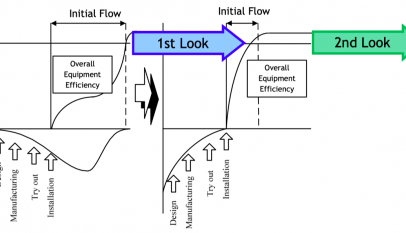

Improve

Identify and test solutions to the Critical X. Rollout out solutions that eliminate the Root Cause

- Regression analysis

- Design of experiment

- Error proofing

- 5S & Visual management

- FMEA

Control

Sustain the improvement by standardizing the new process and monitoring Critical X’s & Y

- Control plan + chart

- Audit plan

- Total Productive Maintenance

- New process capability analysis

- FMEA