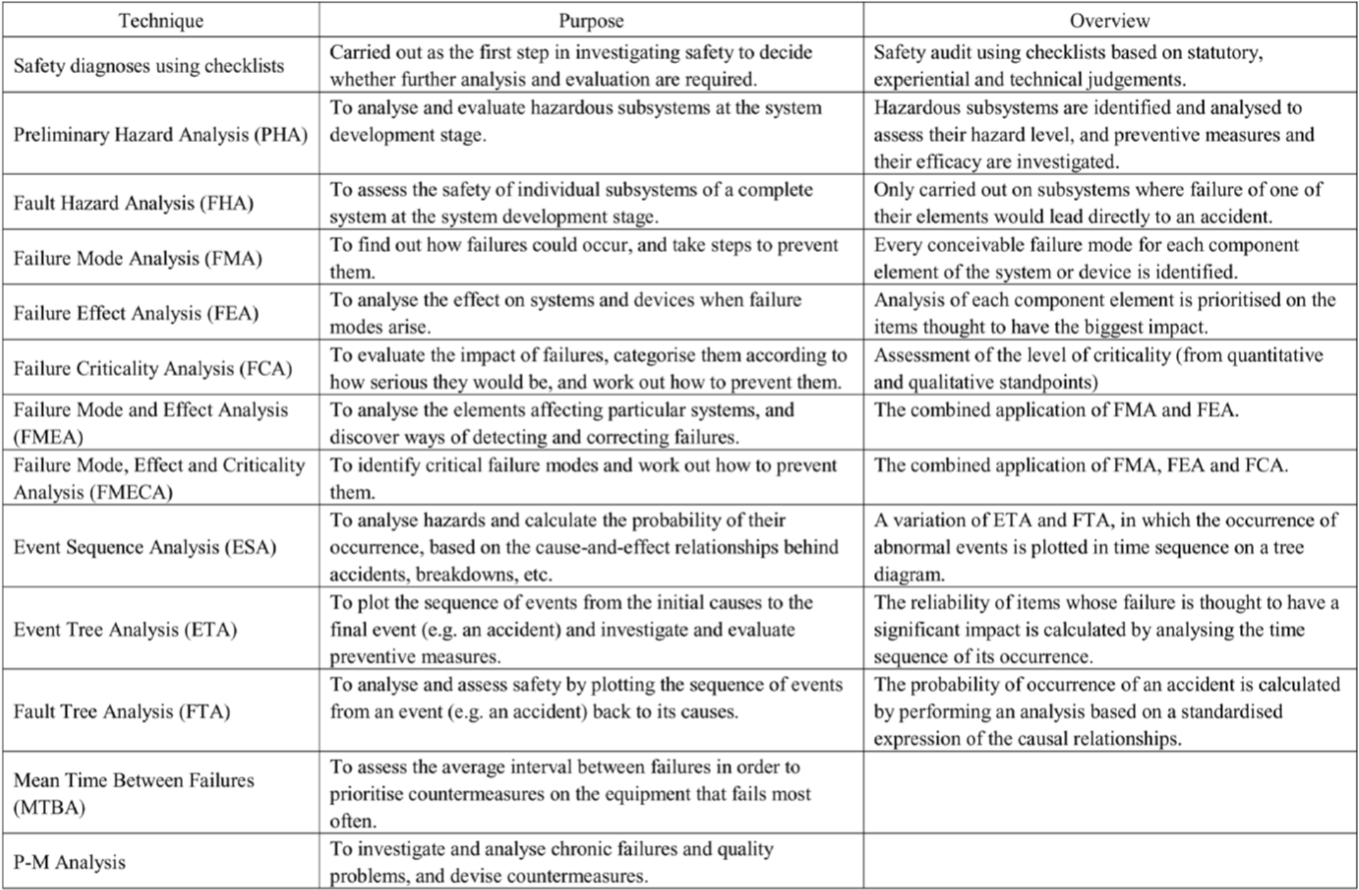

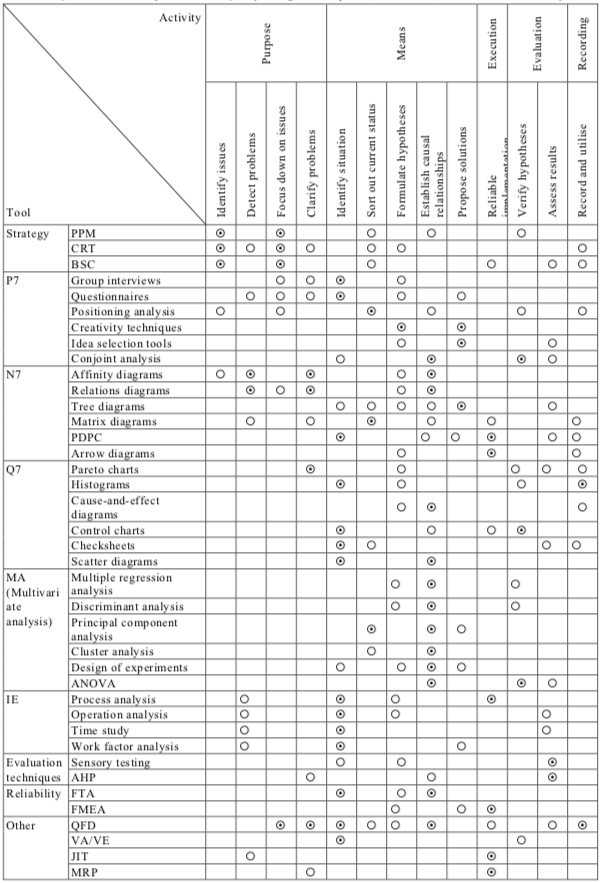

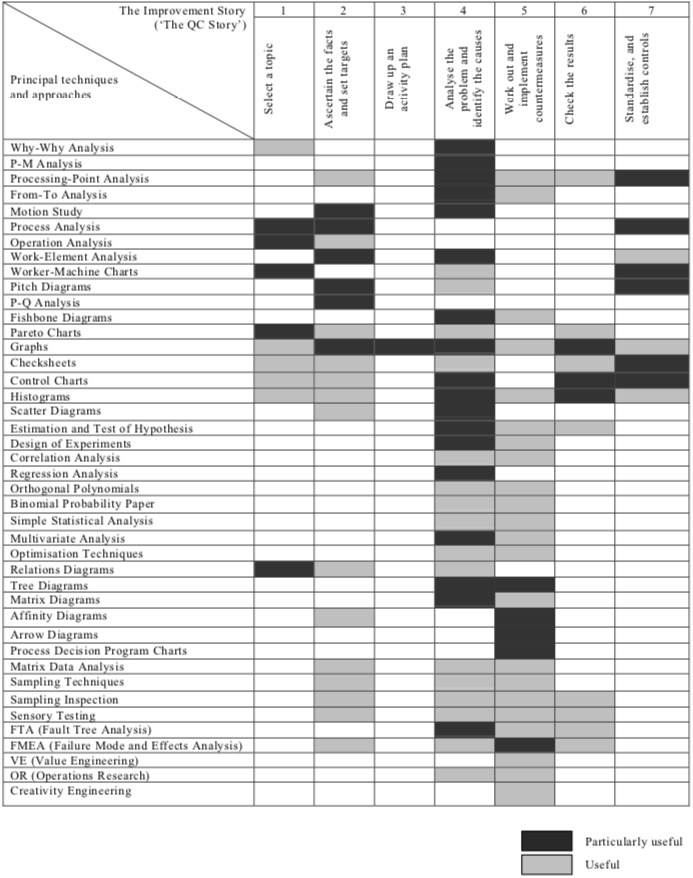

Although a Focused Improvement is an intensive project that is supposed to be completed within a short time span, it can be particularly difficult to produce good results when the problem being addressed is a chronic one. It is therefore important to make effective use of all the tools and techniques most suitable for the task at hand (failure analysis techniques, industrial engineering methods, QC tools, value engineering techniques and one’s own original techniques). Many chronic issues can be resolved rapidly and skilfully through the use of P-M Analysis, a powerful failure analysis tool.

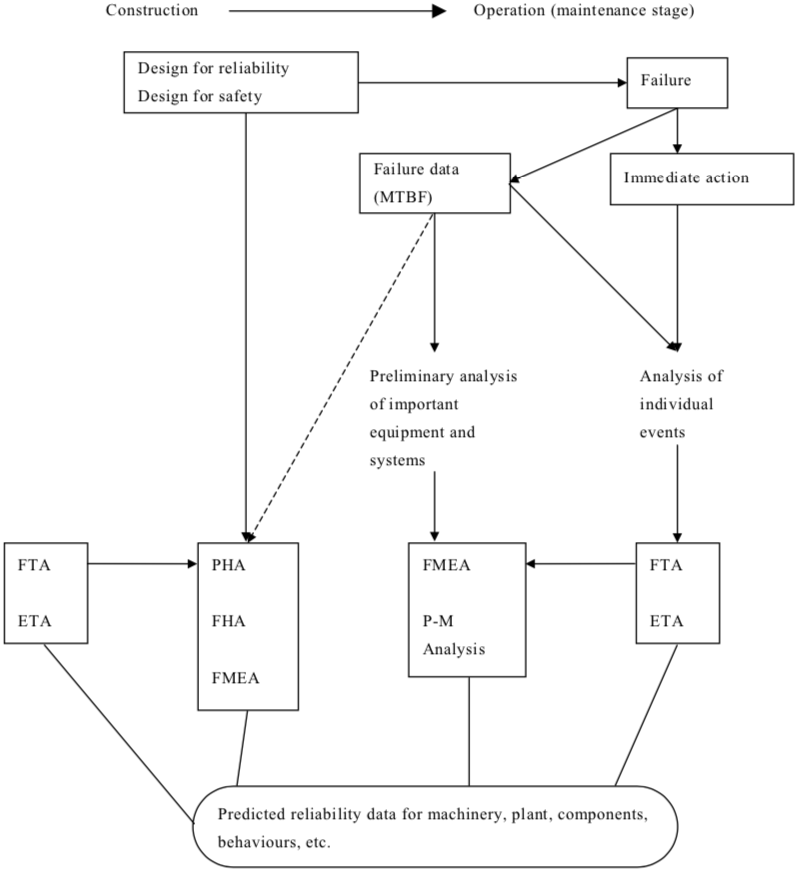

Figure “Use of Failure Analysis Techniques during Equipment Construction and Maintenance” shows how failure analysis techniques should be used during equipment construction and maintenance. In-house failure data (MTBFs), manufacturers’ data, test data, and other data for predicting the reliability of machinery, apparatus, components, behaviours, etc., are helpful for performing internal forecasting reviews on equipment.