TPM

Autonomous Maintenance. Step 6: Standardization

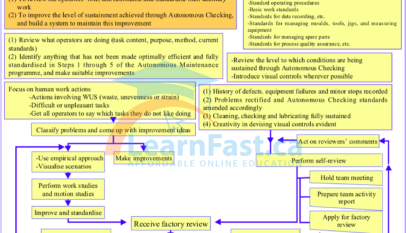

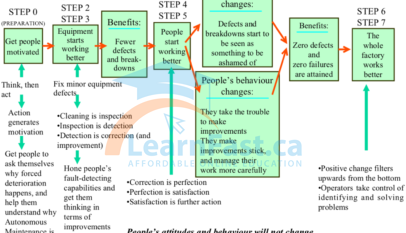

In Step 6, while sustaining optimal conditions through Autonomous Checking, operators keep on making improvements and record any defects, equipment failures, or minor stops that occur.

Read More »What is Autonomous Maintenance?

Operators should look after their equipment Autonomous maintenance aims to create a scenario where all operators look after their equipment, carrying out routine checks, oiling and greasing, replacing parts, doing simple repairs, spotting problems at an early stage, checking precision, and so on. Operators need to understand their equipment Autonomous…

Read More »How would you start implementing a TPM program?

We are a winning team that throughout the TPM philosophy leverage the talent of people, assuring the process and assets optimization.

Read More »TPM 3 Levels – path to World-Class Manufacturing

5S Autonomous Maintenance Blog Change Management Early Equipment Management Early Product Management Education and Training Focused Improvement Instructor Training Manufacturing Support Planned Maintenance Quality Safety, Health and Environment TPM TPM Introduction World Class Manufacturing

Getting to Level 3 of Total Productive Maintenance will require a LOT OF hard work, but it’s doable. Listed below is a 20-Step process on how to get there, steps 1-12 are part of Level 1 (Excellent Factory), steps 13-17 – Level 2 (Excellent Supply Chain) and finally, steps 18-20…

Read More »