Before going on to describe how equipment design should influence product design and development, this section briefly explains the concept of factory-friendly product design, the principal function of TPM in this field. Although equipment design should influence product design and development, the product design and development department must be fully receptive to this idea, or it will not happen. To illustrate the kind of thing that the department must be prevailed upon to do, the following explanation is interspersed with real-life examples.

(1) What is a ‘factory-friendly product’?

A “factory-friendly product” is one whose means of production are inexpensive and readily available and that can be produced safely using simple procedures and equipment. In the case of a product or component produced mainly by machining, for example, the requirements for factory-friendliness would probably include some or all of the following:

- Easy to create a reference surface on

- Easy to clamp

- Easy to position in the holder

- Resistant to going out of centre

- Scratch-resistant

- Burr-resistant

- Easily machined

- Easily screened for defectives

- Easily measured

- Resistant to ingress of cutting debris

- Easy to remove cutting debris from

- Easily assembled

- Easily automated

(2) Five Strategies to Achieve Factory-Friendliness

To design and develop a product that is factory-friendly in the ways listed above, the five strategies described below need to be employed:

Before starting to design the product, identify any specific issues concerning the factory-friendliness of current products, and build the solutions to these issues into the design of the new product. To this end, you will need to employ the first two strategies:

- Collect and utilize information about the current product;

- Identify the requirements for factory-friendliness, and work out how to satisfy those requirements, by carrying out a process analysis on current products.

Next, work out in advance what the problems will be. This is done by carrying out a design review at each stage, from conceptual product planning and design through prototyping and testing. Once you know the problems, you can start designing the solutions for the product. Here you will need to employ the next three strategies:

- Carry out a process analysis on the new product, to find out what would make it factory-friendly, and how that could be done;

- Carry out a design review on the new product, to analyze its potential for generating defectives. Work out what would help prevent defectives being generated, and how that could be done;

- Identify potential volume-production problems at the prototyping, testing and evaluation stages, to find out what would make the product factory friendly, and how that could be done.

When doing this, you will need to

- Factor in volume-production conditions;

- Identify potential problems by developing evaluation methods;

- Carry out design reviews using checklists and other standardized documents;

- Proceed systematically, using highly-skilled, knowledgeable staff effectively.

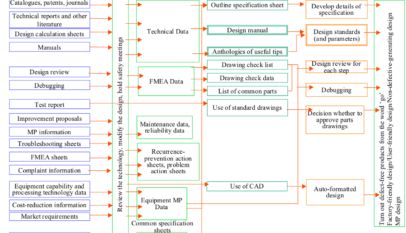

To implement the five strategies, you will need to draw up checklists. This task will be made easier by making good use of MP information on existing products, and organizing this information well (see Figure “Collecting and Utilizing Technical Information for Product Design”).