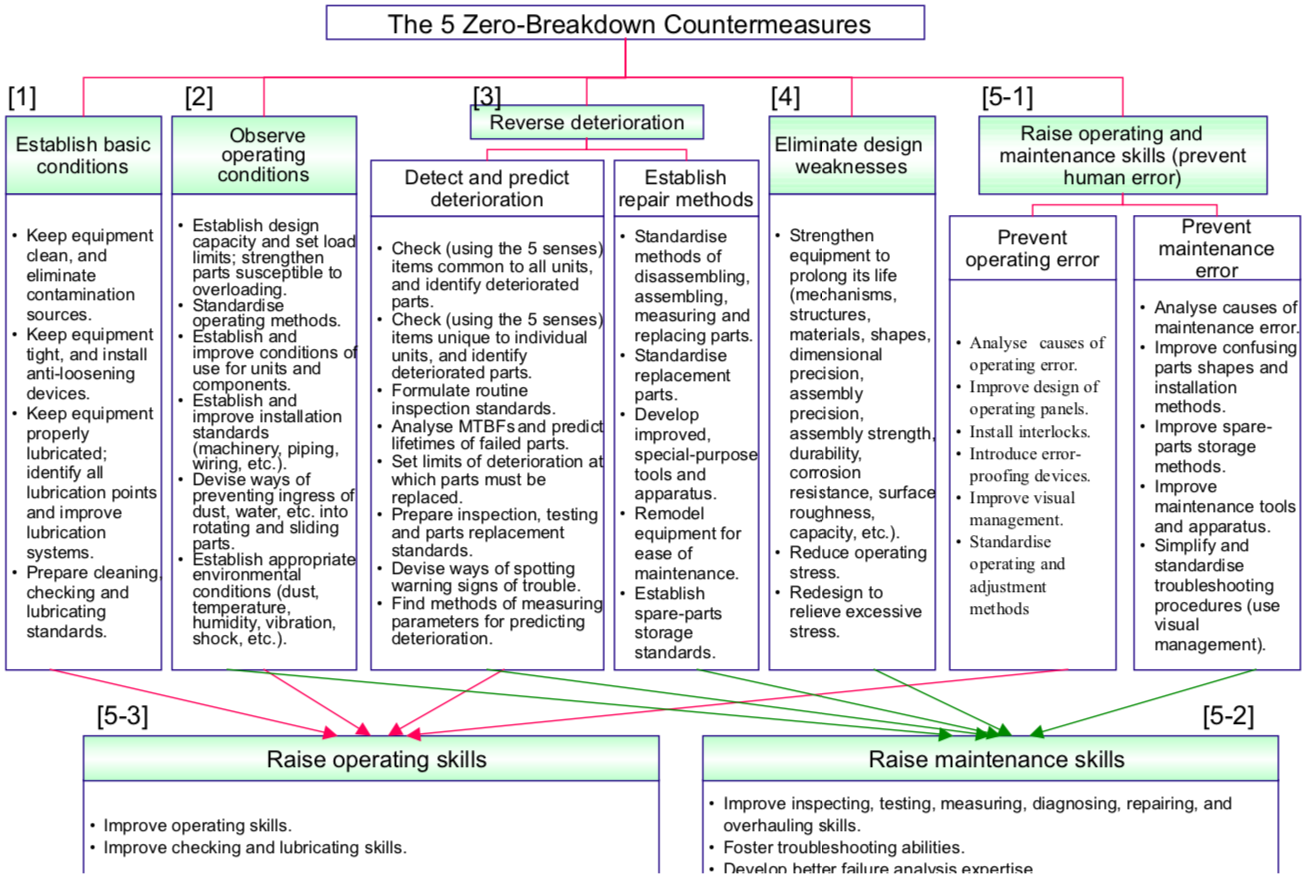

The seven concepts behind achieving zero failures have been described. The fact that actions (3) through (7) are required indicates that neglecting to carry them out is a common cause of failure. These actions are so important that they are identified as the 5 Zero-Breakdown Countermeasures.

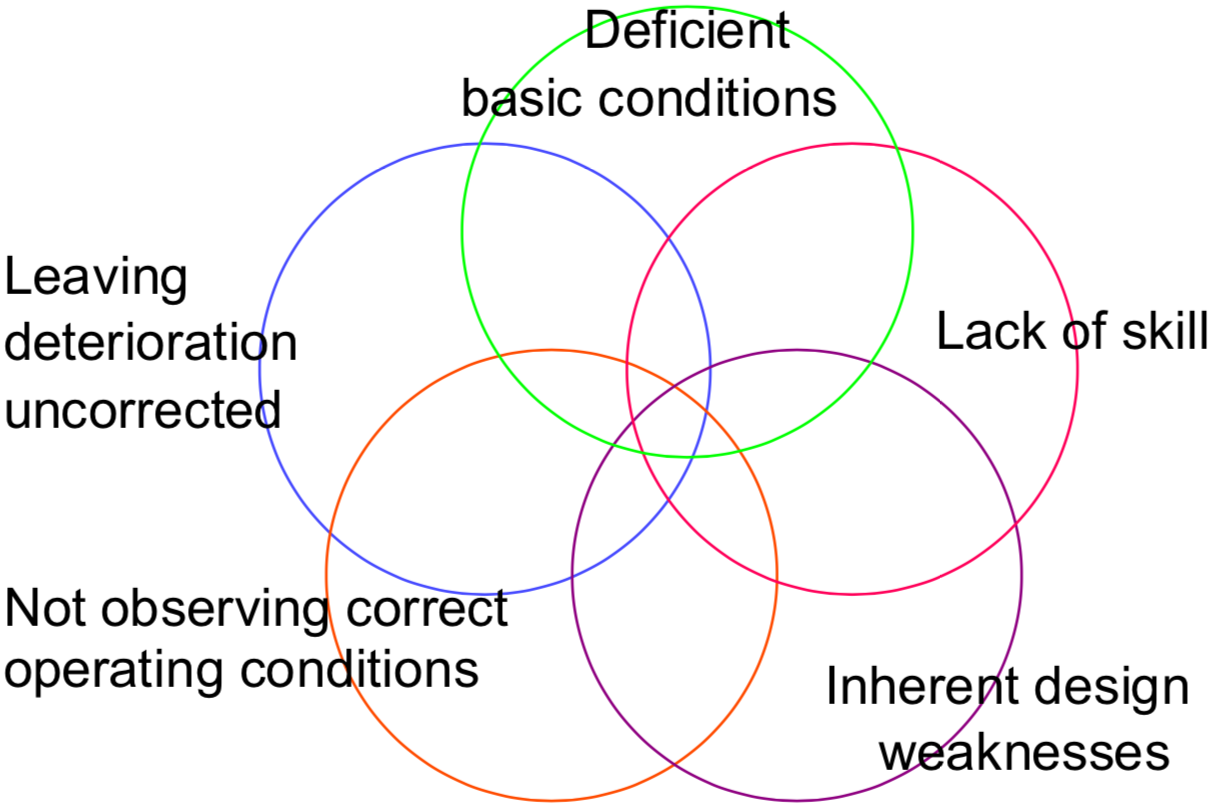

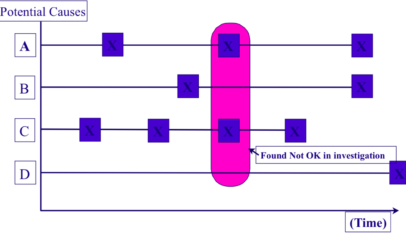

Neglecting a single one of them can lead directly to a failure, but more often than not, failure is due to neglecting several in combination, as shown in Figure “Overlapping Causes of Breakdowns”. This means that it is not always possible to eliminate a particular kind of failure by implementing only one or two of the countermeasures. Sometimes, even after numerous improvements have been made, failures continue to happen.

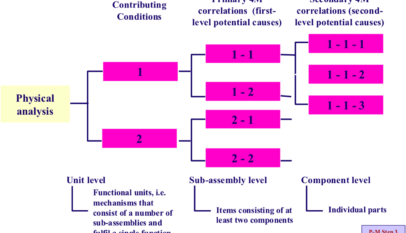

The fastest way to achieve zero breakdowns is to implement all five countermeasures in order to identify and deal with every latent problem. Figure “The 5 Zero-Breakdown Countermeasures” shows the usual priorities within the countermeasures. This figure has been generalized to make it applicable to any kind of equipment and can be used for ensuring that all aspects have been covered.