Due to decreased warehouse space, consumer packaged goods companies are forced to have shorter production runs, which leads to increased number of changeovers.

Agenda

Training Objectives and Expectations

- To reduce C/O time by at least 50%;

- To develop training material to roll out across all production areas.

Six major equipment losses

- Major Stops

- Minor Stops

- Changeover Loss

- Startup/Shutdown Loss

- Speed Loss

- Quality Loss

Definition “Changeover”

The time from when the last case of a run was produced to the first case of the next run.

Note: C/O loss and Start-Up Loss are closely related

Measure: Time (mins)

Definition “Startup and shutdown loss”

The time required to reach ‘normal’ running condition after a changeover or beginning of the week, or after PM. (Shutdown is the time taken to ramp down during a shutdown for C/O, PM, or end-of-week).

Note: ‘Normal’ running condition is when the production machine reaches average efficiency.

Measure: Time (mins)

Changeover vs. startup

Categories of changeover

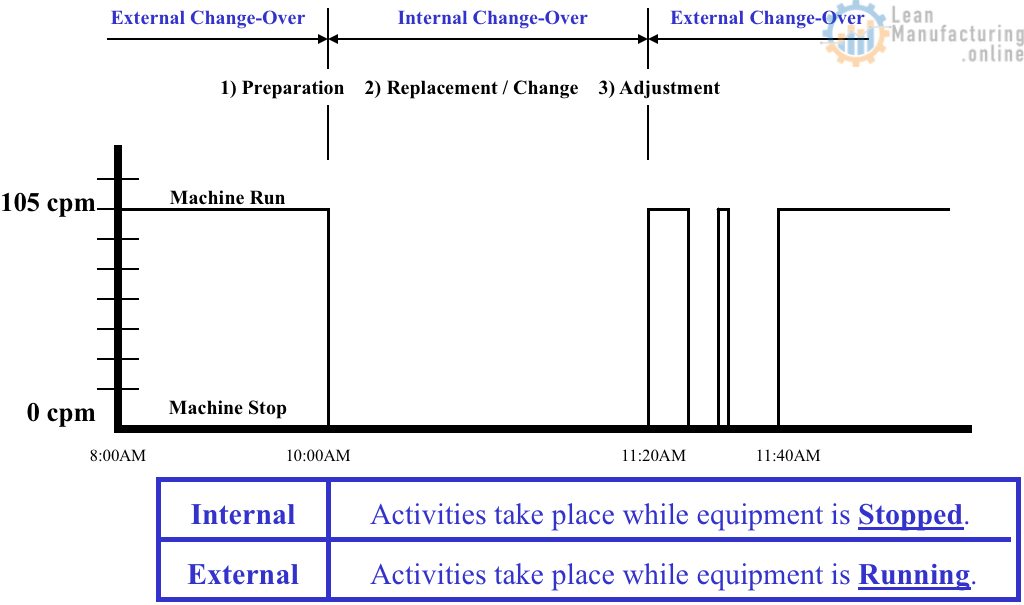

External vs. internal

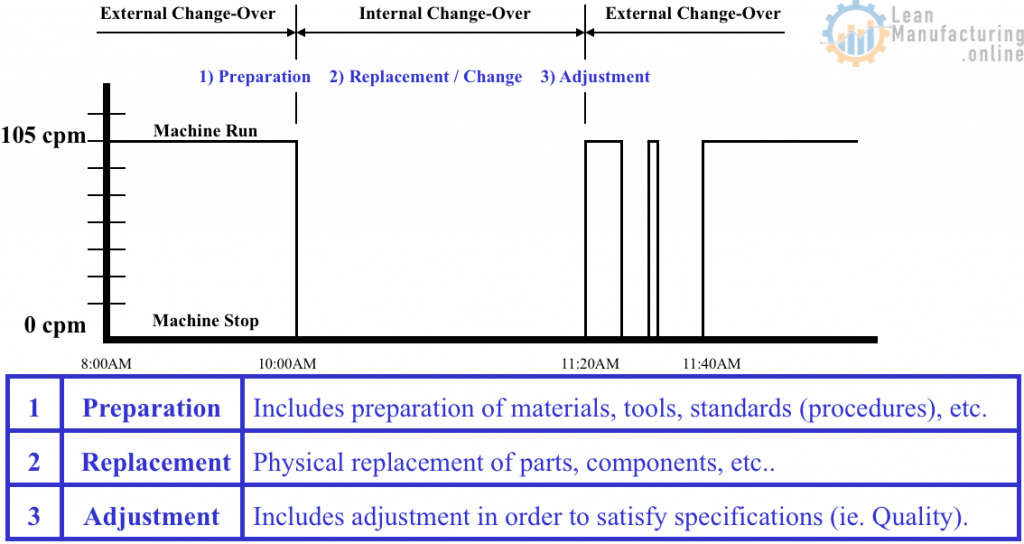

The 3 Components of C/O

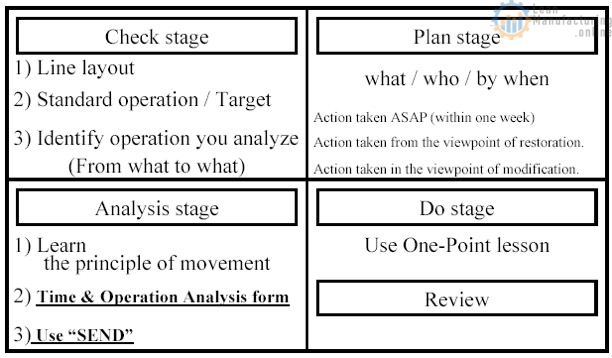

7 Steps for Focused Improvements – Changeovers

Step 1: Form C/O Team

Step 2: Understand Present Status (Check)

Step 3: Time & Operation Analysis (Analyze)

Step 4: Plan Improvement Items (Plan)

Step 5: Implement Improvements (Do)

Step 6: Standardization

Step 7: Training

Step 1: Form C/O Team

- Define the team members of the Focused Improvement (FI)

- Set targets for C/O time reduction (50%)

- Agree on a plan for C/O FI activities (who, what, when, where)

Step 2: Understand Present Status

- Record actual Changeover on video for review in the boardroom

- Use the “Time & Operation Analysis” worksheet to describe the actual (current) Changeover procedure

- Use a stopwatch in a boardroom to review tape while filling in the worksheet

Step 3: Time & Operation Analysis

Step 3: Analyze Problem

- Identify Internal changeover operations that can be performed during External changeover activities

- Apply the S.E.N.D. methodology to all steps on the “Time & Operations Analysis” worksheet

S.E.N.D. Methodology

S.E.N.D. is a tool to help facilitate improvement (reduction) in Changeover time:

- Simultaneously

- Easier

- Eliminate Number of Operations (or Steps)

- Eliminate Distance between Operations (or Steps)

Simultaneously

Definition:

- Perform tasks in parallel that were once done in series, at the same time vs. separately

- Examples:

- Tightening two thumbscrews at the same time

- Bring all change-parts to the line simultaneously (on a cart for instance) vs. one-by-one

Easier

Definition:

- Modify a task such that it takes less time, materials/tools, or thought to perform.

- Examples:

- Eliminate the need for screwdrivers by using thumbscrews

- Color code change-parts so it is clear which part goes with which size

- Etch or Mark a change-over setting

Eliminate Number of Operations

Definition:

- Reduce the total number of tasks (operations) that are performed during the changeover

- Examples:

- Replace six (6) bolts with one (1) quick-release

- Use a change-over cart (all change-parts and tools required for the job are on the cart)

Eliminate Distance Between Operations

Definition:

- Reduce the physical distance between tasks (operations) to eliminate unnecessary walking time

- Examples:

- Ensure all bolts or thumbscrews are physically accessible from one side of the equipment

- Use a change-over cart to minimize walking back and forth from a change-part storage location

S.E.N.D. Summary

Note:

- Often many tasks can be combined to achieve several components of S.E.N.D. (ideal):

- Example: Changeover Cart

- Simultaneous because all parts are brought out at the same time

- Easier because the cart is on wheels and parts don’t have to be carried

- Number of steps reduced because obtaining change-parts is now a single step (vs. multiple trips)

- Distance reduced because only need to make one trip for change-parts

Step 4: Plan Improvement Items

- Develop an improvement implementation plan (who, what, when, where)

- These are the actions resulting from the S.E.N.D. analysis on the “Time & Operations Analysis” worksheet

Step 5: Implement Improvements

- Execute the improvement plan

- Verify actions are effective

- Collect detailed setup information (to be used in Step 6)

Step 6: Standardization

- Develop standard set-up sheets

- These sheets are to be used each time when performing the change-over

- Specific information, documenting change-over steps, settings, locations (where the cart can be found), color schemes, etc.

- Measure “after” changeover times and compare with “before” situation

Step 7: Training

- Develop an activity board

- Provide training sessions for new changeover process (track training records)