A few weeks ago, we discussed a tool to understand the gaps in the current situation of the maintenance department.

In this post, I would like to share the “Strategy 🔺” that describes the steps from the Foundation Phase to achieving 100% Asset Reliability.

Fundamental Phase

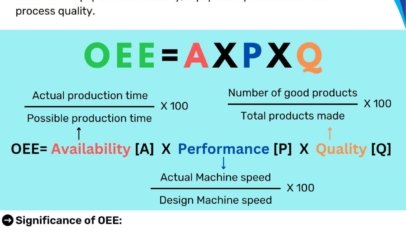

Once you assess gaps, create the plan and execute it, you should see an improvement in your major KPIs.

The next step would be to move to the Building phase; let’s focus on the essential points:

👷 🩺 Condition-Based Monitoring or Failure Prediction. Once the PM program has been established, it is vital to determine which failure mode will be monitored, for instance, wearing or misalignment, and which measure will be monitored, for example, temperature. Tools to use, laser shaft alignment system; vibration analysis; infrared inspection (thermography); oil analysis, etc.

👩🏾⚕️ 🔧 Operators-Technicians. In the Total Productive Maintenance methodology, a pillar called Autonomous Maintenance will help organizations up-skill production staff and transfer regular maintenance duties to the operators. I plan to bring a series of posts to your attention.

🚎 📆 Asset History. Knowing which critical assets are most important to the operation will better synchronize the available maintenance resources to prioritize work orders and improve assets and areas that give us the most for the investment. Recurring Matrix can help track past issues, what was done to prevent breakdown from happening in the future, and the measure’s effectiveness.

🖥️ 🛠️ CMMS integration with ERP. Unless your company has decided to use SAP (or similar) with Maintenance Module from the beginning of CMMS implementation, a link must be established to connect existing ERP with maintenance management software. Based on my experience, it will reduce the time spent on the maintenance coordinator’s financial processing load. Standardize sub-systems and functions that interface and support the CMMS, such as equipment numbering, parts numbering, equipment classes and categories, accounting charge numbers, barcoding standards, standard descriptions and nomenclatures, and customized key performance indicators reports.

Let me know if you want to discuss other strategy triangle steps in depth.