Purpose of Lubrication

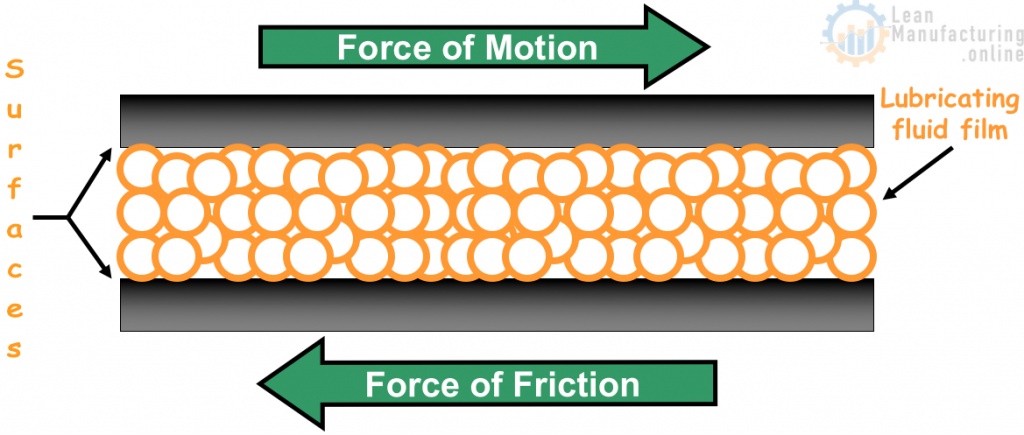

As shown in the figure, the lubricating fluid film between the two surfaces keeps the surfaces from making direct contact. The very small particles of the lubricating fluid in the film move over each other reducing the friction between the surfaces.

Training Objectives

- Describe the purpose of lubrication.

- List the types of lubricants used.

- Provide examples of the application of lubricants.

- Identify the lubrication receptacles.

- Outline the problems of over and under lubrication.

- Describe lubrication tools used.

- Identify the hazards of cross contamination.

Friction

- Any movement between solid materials, liquids and gases produces friction. Friction is the resistance to motion between two surfaces in contact.

- Friction produces heat(loss of energy) and causes deterioration.

- Friction is very important! We need friction to walk, to drive, or to stop a car.

- During the operation of any machine, there is a metallic friction between components in motion (chains, bearings, gears).

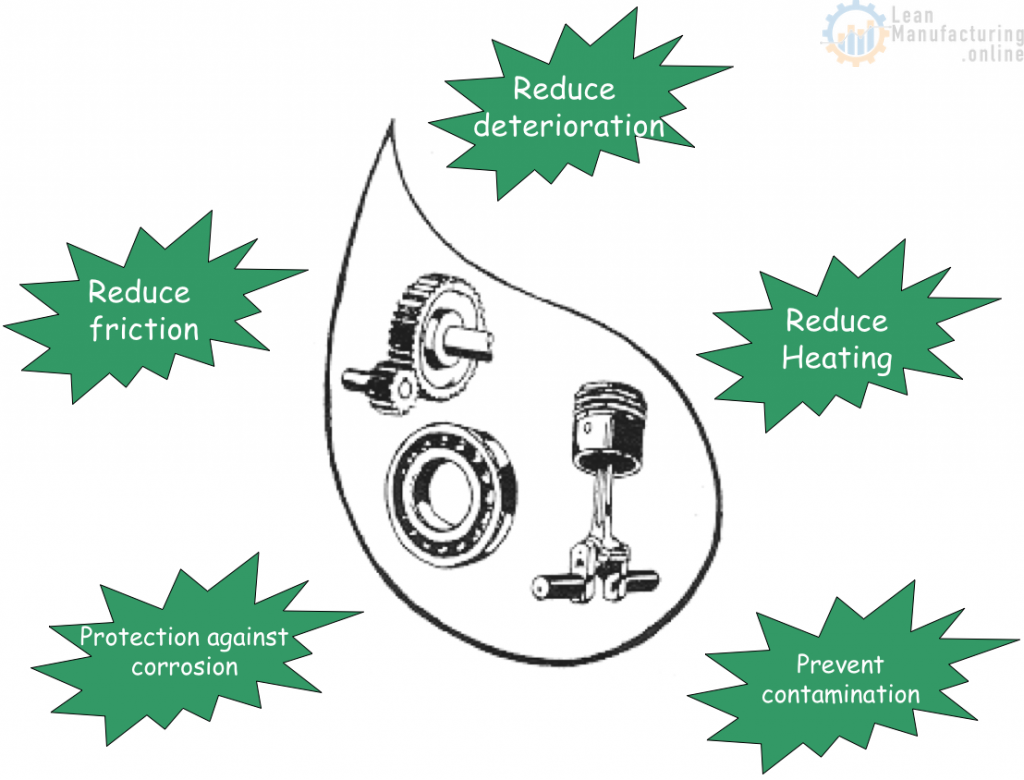

Why Do We Need to Lubricate?

Everyday Comparisons

Reducing the resistance of friction through lubrication decreases the wear to sliding and rotating surfaces.

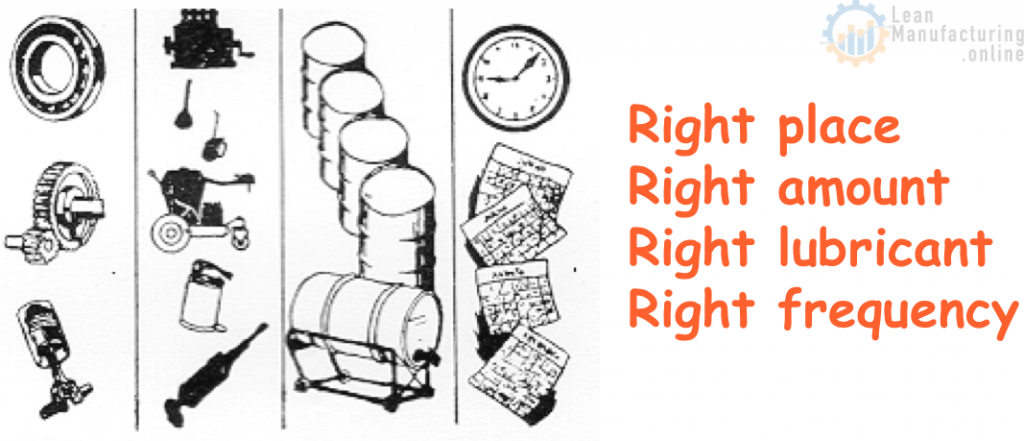

To Achieve the CORRECT Lubrication, We Need:

- Stress that all these aspects of lubrication must be understood and followed correctly.

- Place (location) on the machine

- Amount (how much should you use with each application)

- Lubricant (which one should you use)

- Frequency (how often should you perform lubrication)

Viscosity

Viscosity means the resistance to the flow at a certain temperature.

Low viscosity oil = light oil, free flowing. This oil is used for high speed, low temperature and low pressure.

High viscosity oil = heavy oil, very slow flow.

This oil is used for low speed, high temperature and high pressure.

Viscosity can be related to density or thickness. (That’s not all viscosity is, but this is a good way for the operators to begin to understand it.)

Imagine a styrofoam cup with a hole in the bottom. If you pour honey into the cup, you will find that the cup drains very slowly. This is because honey’s viscosity is large compared to other liquids’ viscosities. If you put coffee in the same cup, it will drain much more quickly.

Viscosity is the measure of a fluid’s resistance to flow. It describes the internal friction of a moving fluid. A fluid with large viscosity resists motion because its molecular makeup gives it a lot of internal friction. A fluid with low viscosity flows easily because its molecular makeup results in very little friction when it is in motion.

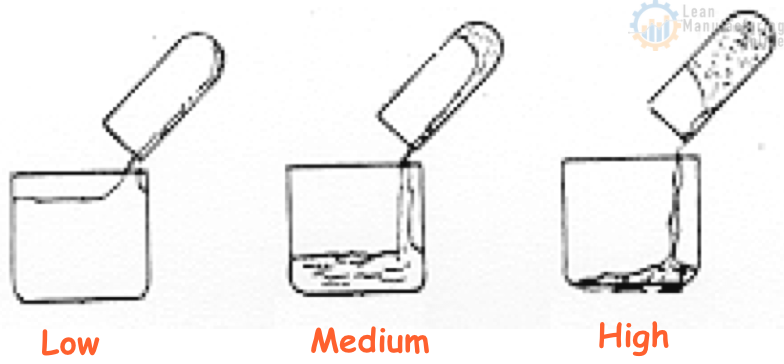

If we pour out three oils with low, medium and high viscosity at the same speed, after a given time we will have:

Types of Lubricants

A lubricant is a material placed between two moving surfaces to reduce friction and wear. Equipment operating conditions determine the selection of lubricants. These conditions include:

- Temperature

- Surface materials

- Working load

- Speed

- Distance between surfaces

Temp – don’t use low temperature base adhesive in a high-speed bearing.

Surface materials – chain lube on chain NOT grease on chain because grease will attract dust and grit and cause an abrasive surface.

Speed – Higher the speed, higher the temperature. Usually at >10,000rpm speed becomes a factor.

Working Load – example would be torque of gear box and load of weight on axle or shaft, shock load, misalignment and starting and stopping.

Distance – the smoother the surfaces, the tighter the tolerances may be. There must be enough clearance between to allow formation of lubricant.

Lubricants used in industrial applications may be classified as:

- Mineral or petroleum oils

- Animal or vegetable oils

- Synthetic liquids

- Greases (food grade)

Ask what type of lubricants do you use at home when cooking? (Example of vegetable oils.)

Oils

Multi-grade oils contain additives that permit the oil to flow steadily across a large temperature range.

The viscosity of oil decreases as temperature increases. Therefore, oils are thinner and flow more easily at high temperatures than at low temps. (Example of syrup in refrigerator and then heated in microwave.)

It is very important for oil to completely cover the surface it is lubricating. If the oil film between two surfaces becomes too thin due to high temperature, friction and wear will increase.

Thicker oils would be used in high temperature conditions to ensure complete coating of the surfaces. Most equipment manufacturers will designate the correct type of oil to be used and how often the equipment should be lubricated.

- Lubricating oils come in a wide variety of grades and viscosities.

- Oils with a high viscosity number are thicker than oils with lower numbers. For instance, 20W (W stands for weight) is thinner than a 40W that is much thicker.

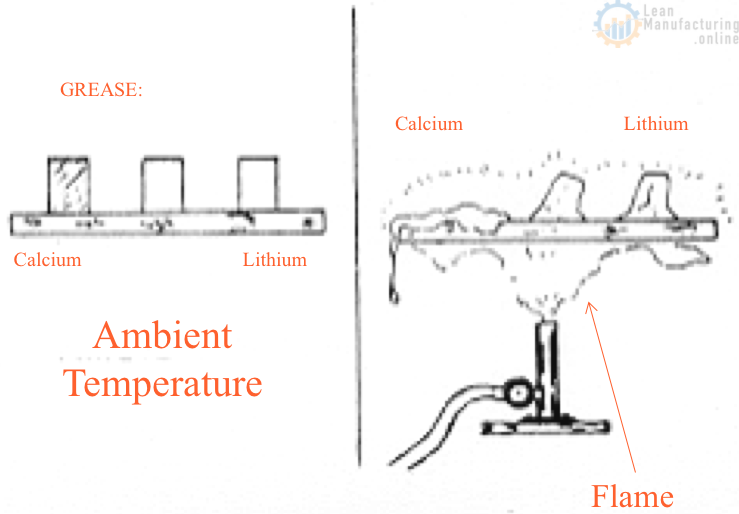

Melt point

Grease melts at different temperatures . Melt Point means the temperature that the grease starts to become liquid.

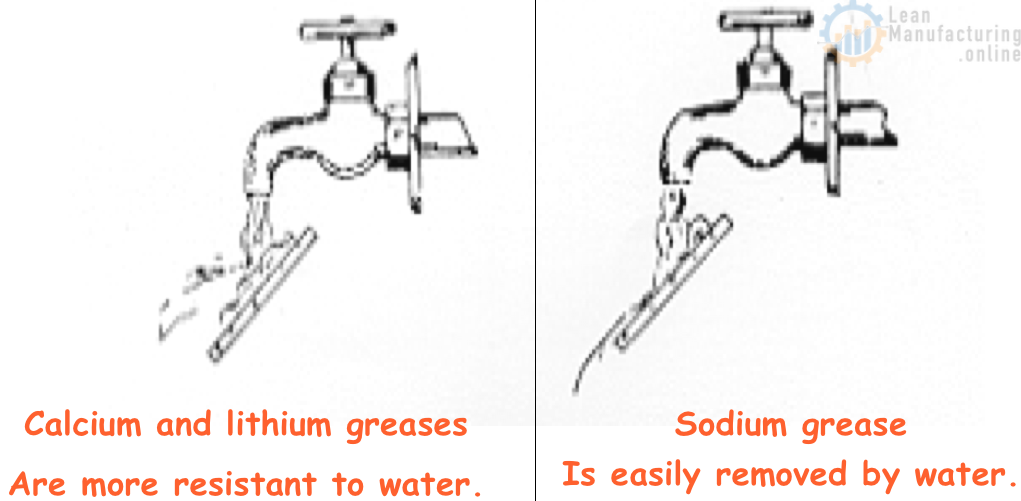

Water Resistance

Some types of grease need to work in presence of water, and because of this they need to have a water resistance.

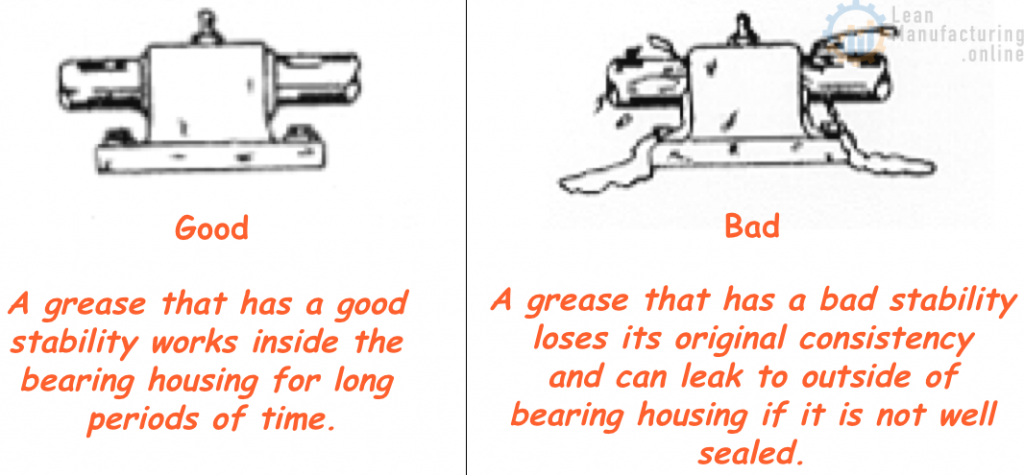

Stability

Stability indicates the period of time that the grease can keep its original consistency.

General:

Greases are mixtures of oil and a wax or soap base.

They range in concentrations from almost solid to a thick oil and are used more in slow operations and when high temperatures are expected.

Some greases are made for special conditions and contain materials such as silicone, aluminum, graphite, or lithium.

Greases are also used when the physical arrangement of the lubricated components makes it difficult to keep the surfaces coated with oil.

Manual Lubrication

Gears, chains and gearboxes. Remember to clean the surface before lubrication. Apply the lubricant directly on or in the surfaces in contact. Remove over lubrication!

Standards

Ask “What lubricant should be used on this machine for gear boxes? At what interval? What method is used?”

Proper Lubrication Techniques

- Receptacles

- Lubrication amounts

- Tools used

- Hazards of cross contamination

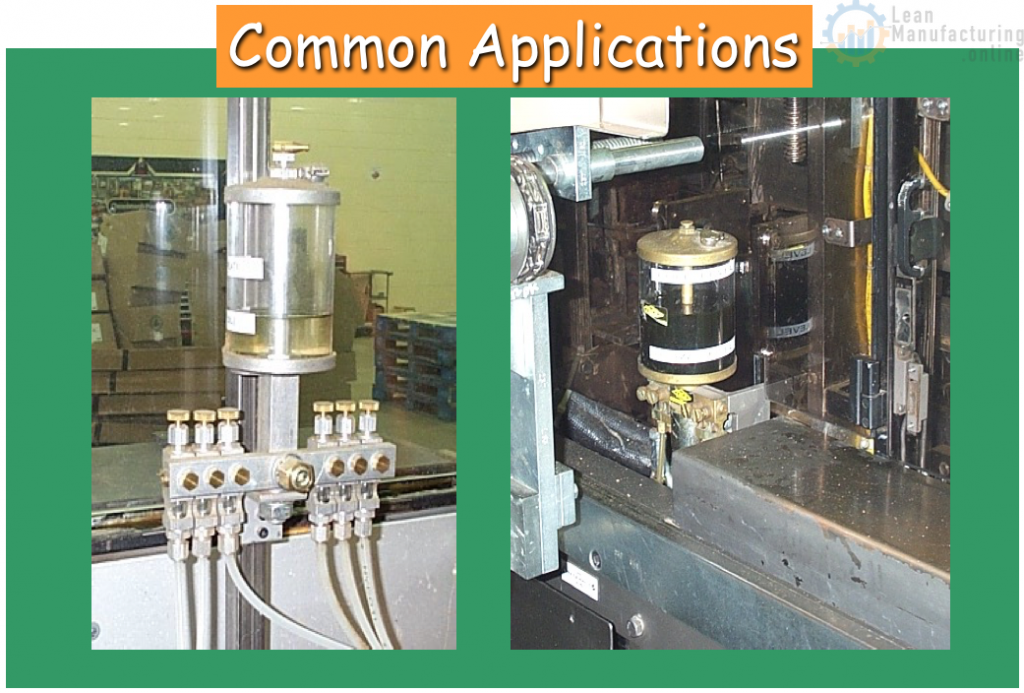

Receptacles

- Zerk fittings

- Oilers

- In-Line Air Lubricators

Zerk fittings

It is very important to clean zerk fittings before adding grease because dirt on the fitting could be forced inside, causing harm to lubricated parts. Remember to clean the fittings after adding grease, also!

Oilers

Oilers are small containers of oil located near the components to be lubricated. They continually lubricate components by gravity flow from the reservoir. Gravity feed rates vary from one machine to the next.

When filling oilers check the following:

- Verify that you are using the correct oil.

- Clean off the glass bulb and area where oiler connects to machine to prevent contamination of oil.

- After filling, look for leaks.

Observe oiler over time and note amounts of oil used. If an oiler never seems to have to be filled or must be filled more frequently than others, this may be a sign of a problem.

TPM Autonomous Maintenance Step 4 Lubrication Module. Part 2