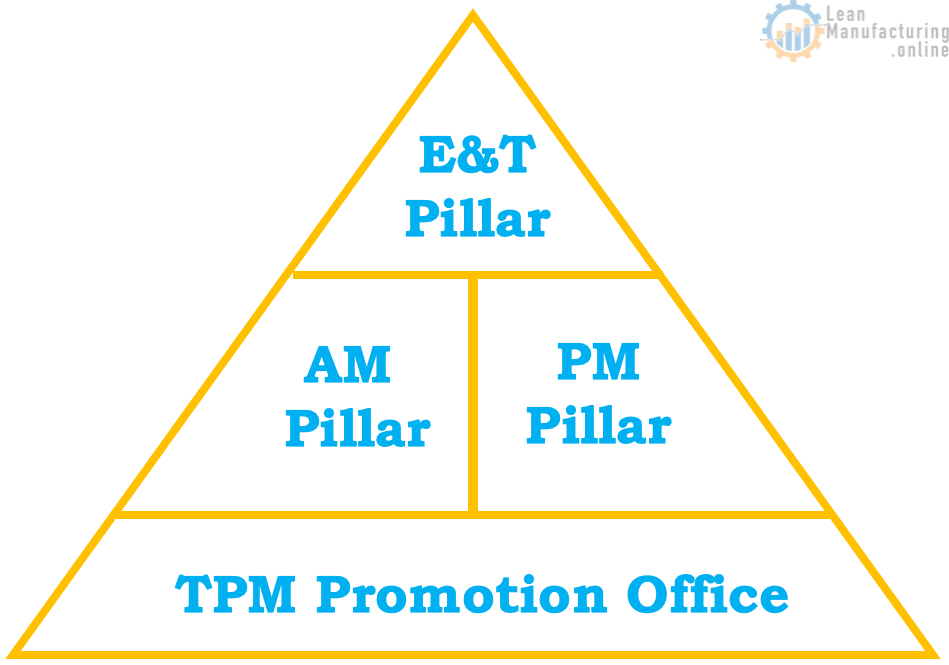

Implementation Team

Values:

- Integrity

- Demand diversity of thought!

- Responsibility and accountability

- Define & communicate roles, responsibilities, and actions plans for teams and individuals!

5W & 1H

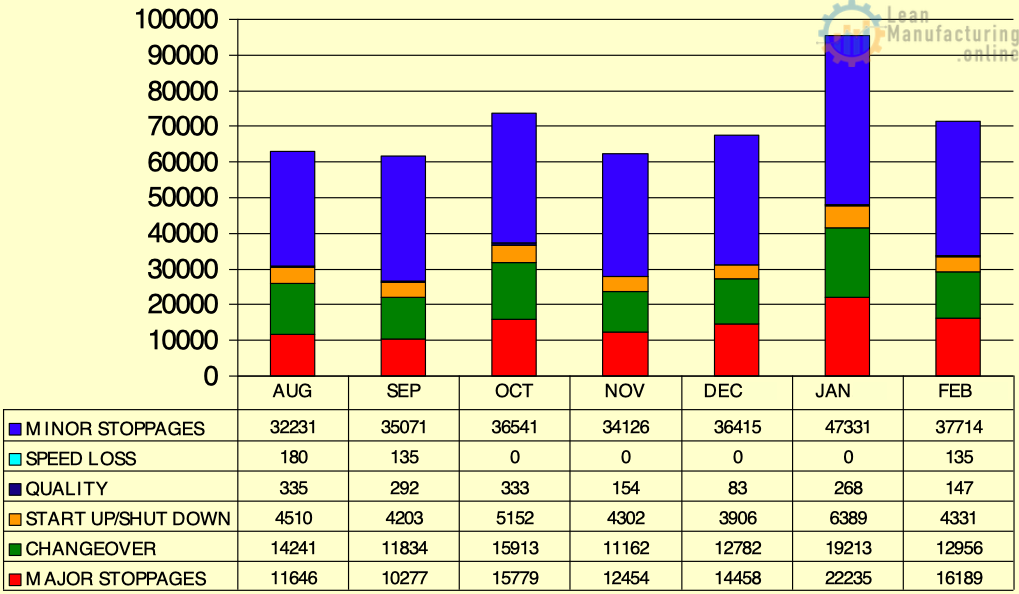

- WHAT: Major Stoppages/Breakdowns

- WHEN: Daily

- WHERE: Packaging Lines

- WHO: Mechanic

- WHICH: N/A

- HOW: Not Enough time to Eliminate

SUMMARY OF PROBLEM:

Mechanics do not have enough time to Eliminate Major Stoppages/Breakdowns that occur daily on the packaging lines.

Why-Why Analysis

- WHY-1: Mechanics are still having to perform basic, routine preventative maintenance & repairs;

- WHY-2: Operators do not have the Skills & Knowledge to assist;

- WHY-3: NO FORMAL TRAINING PROGRAM EXISTS.

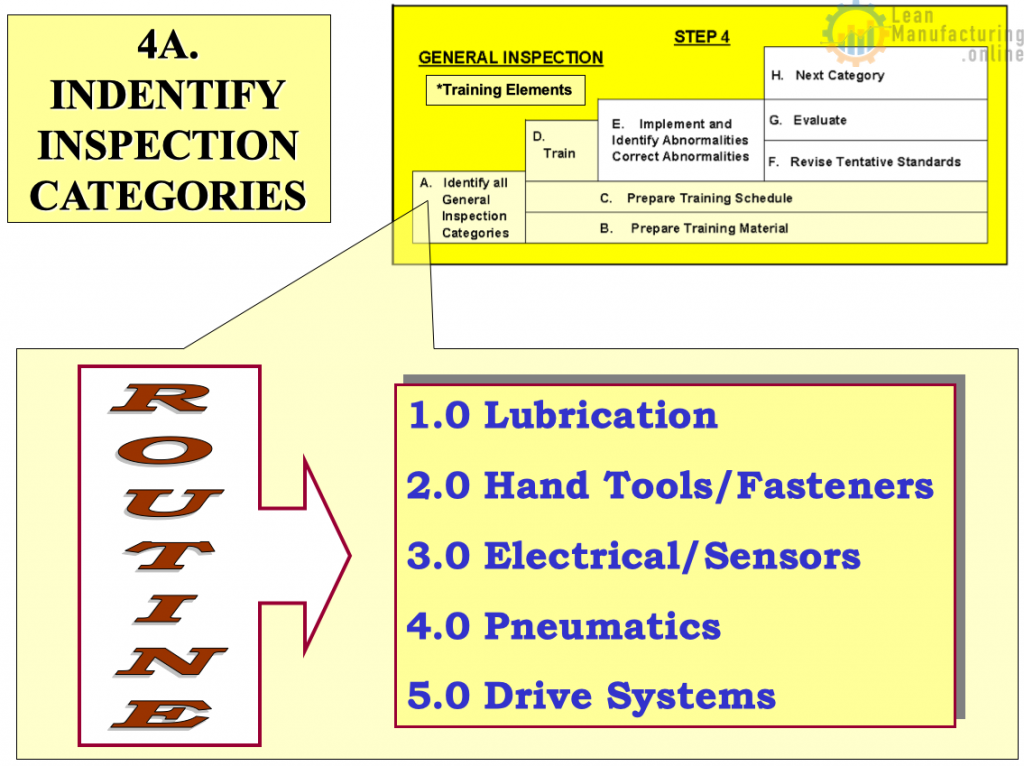

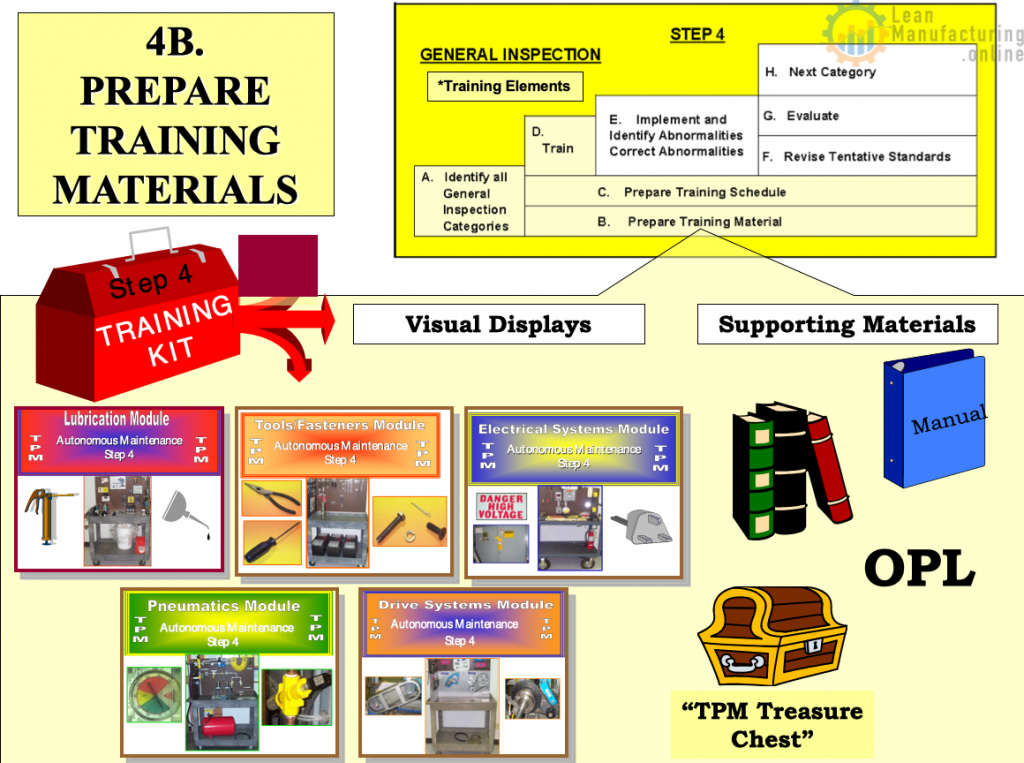

Developing training program

Define Skills & Knowledge

Each Module Developed with clear objectives:

- Understanding of Normal vs. Abnormal Conditions;

- Safe and proper use of or conditions for application;

- Proper Component Identification;

- Demonstrated Abilities and Skill Assessments.

Please use links below to get access to all 5 modules

- 1.0 Lubrication

- 2.0 Hand Tools/Fasteners

- 3.0 Electrical/Sensors

- 4.0 Pneumatics

- 5.0 Drive Systems

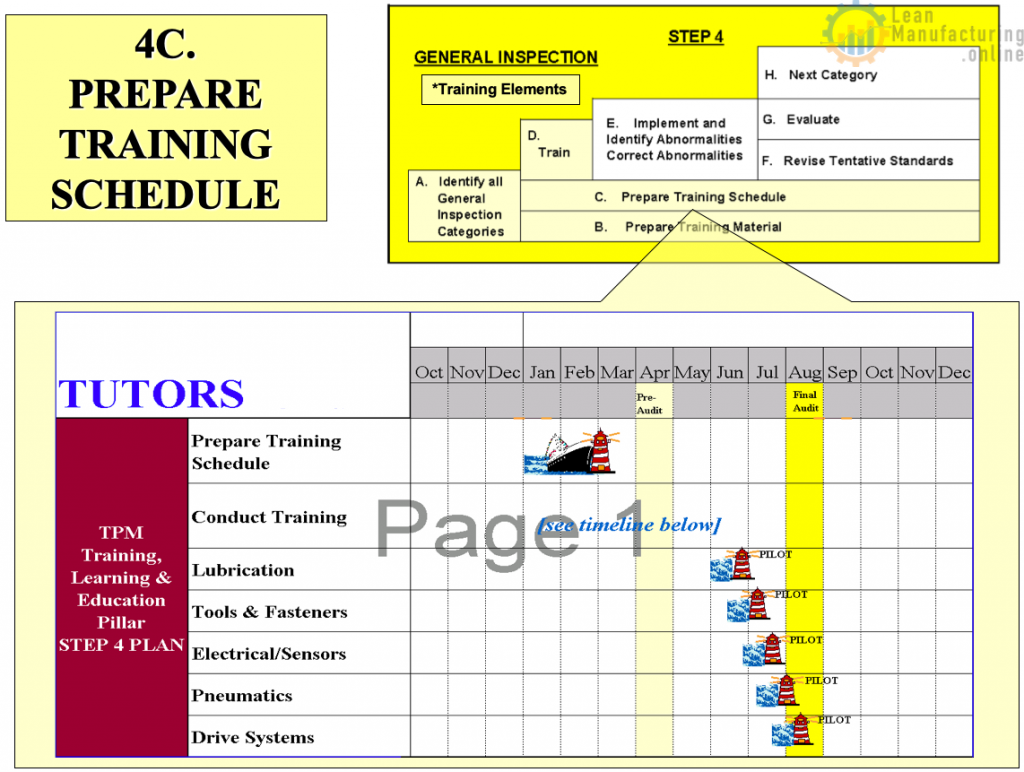

Create training schedule

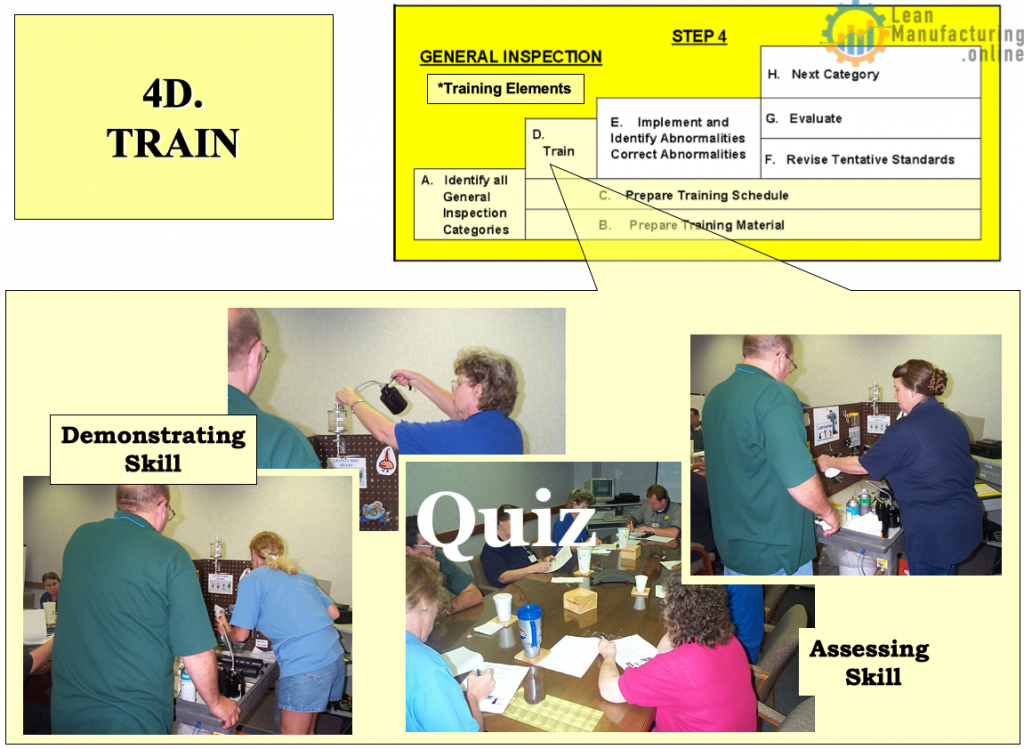

Train

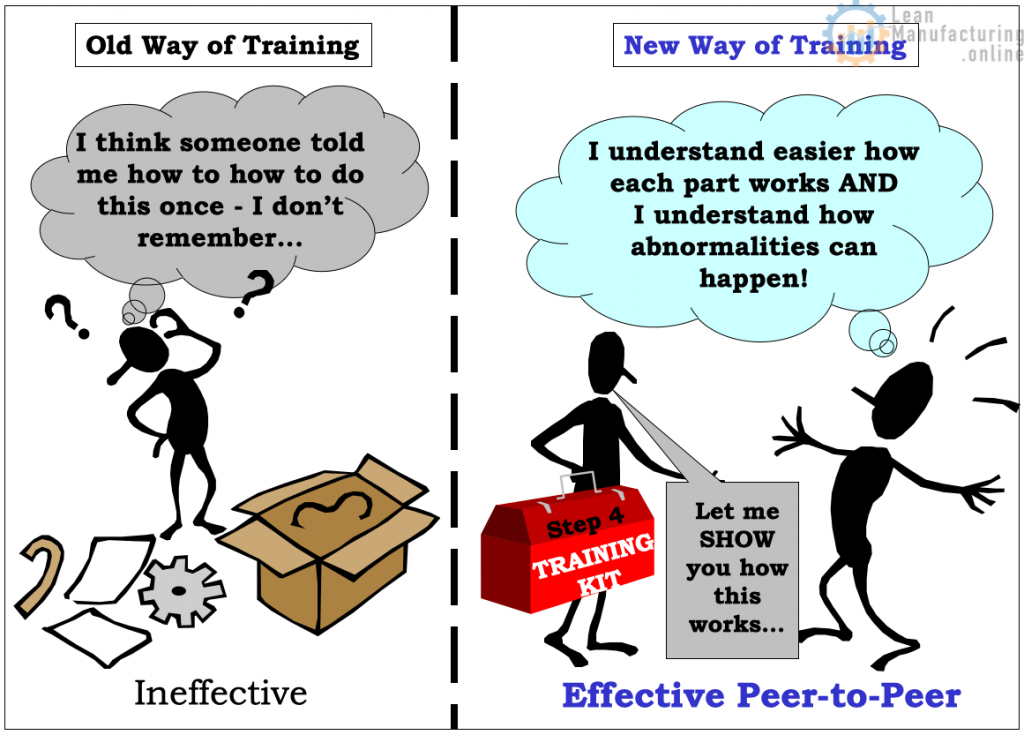

Benefits Old vs. New Training

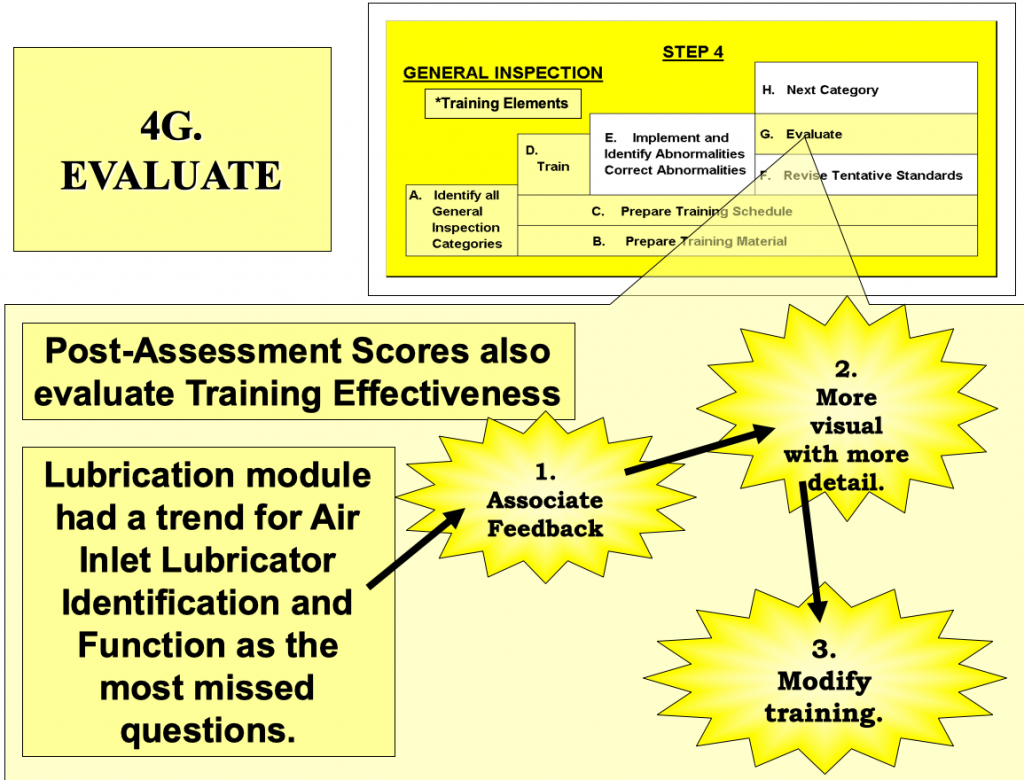

Training evaluation

Group composite scores from Pre-evaluation compared to Post-evaluation scores to evaluate effectiveness. Individual Associates must have a minimum passing score of 80% to move to the next module.

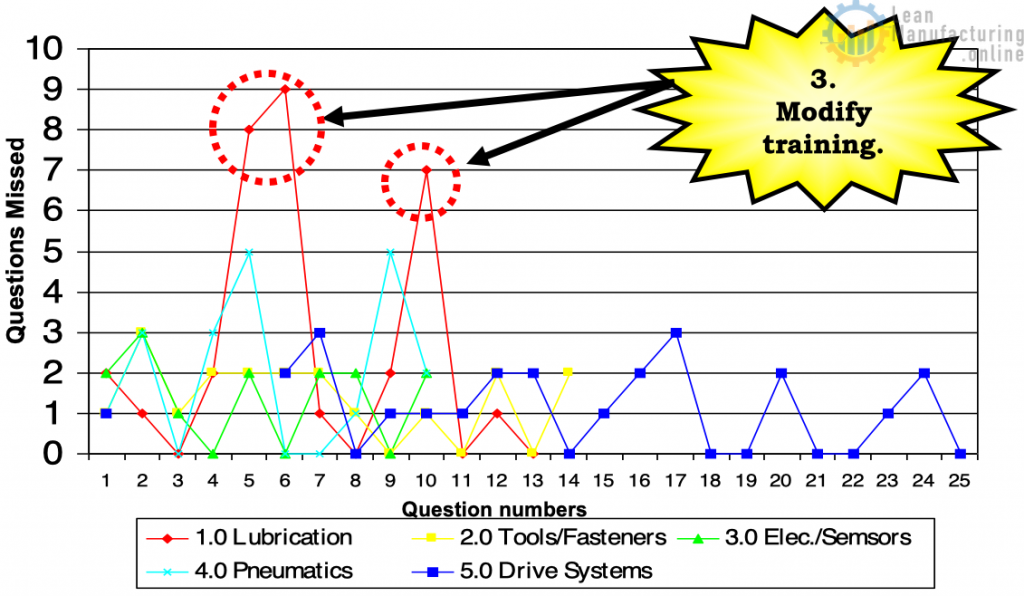

Knowledge and Skill Assessment Results. Module Session Average Scores

Pre / Post

1.0 Lubrication: 61% / 94% (100% passed)

2.0 Hand Tools/Fasteners: 75% / 94% (100% passed)

3.0 Electrical/Sensors: 52% / 92% (100% passed)

4.0 Pneumatics: 60% / 96% (87% passed)

5.0 Drive Systems: 50% / 92% (100% passed)

Post-Assessment Knowledge Evaluation

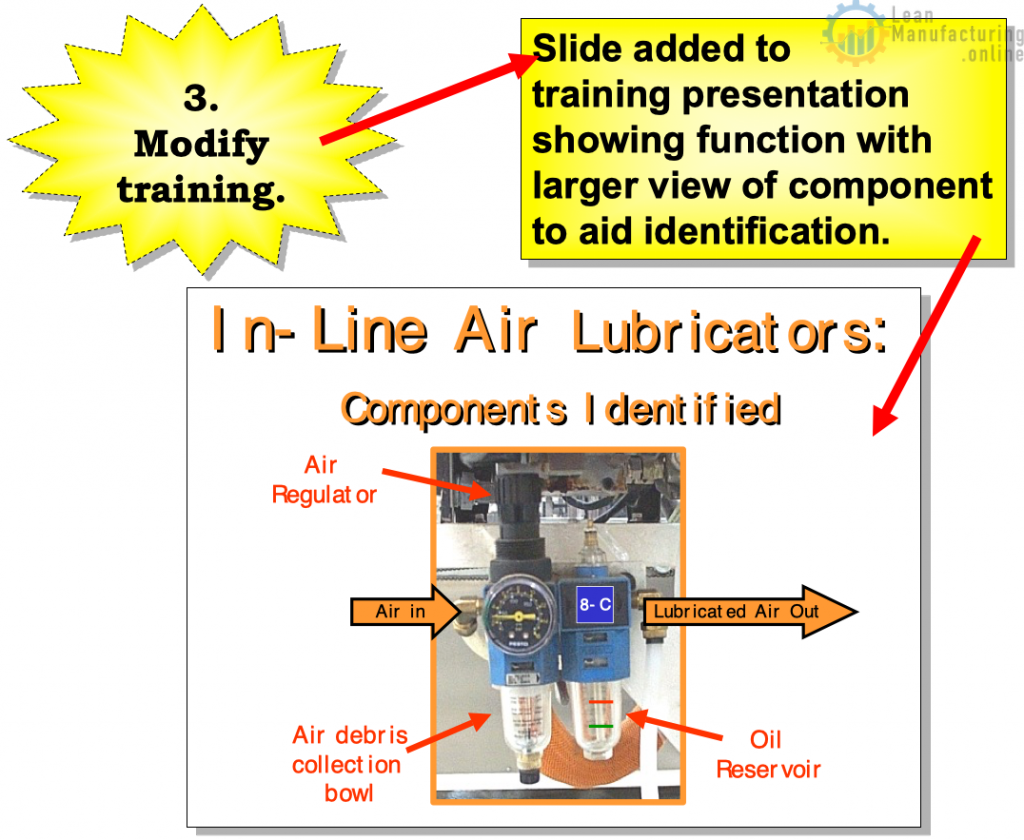

Modify training

Associate Feedback = HIGHER MORALE:

- “I wish I had this training 20 years ago!”

- “I can use this.”

- “This training makes sense.”

- “No longer failures, but Planned Activity”.

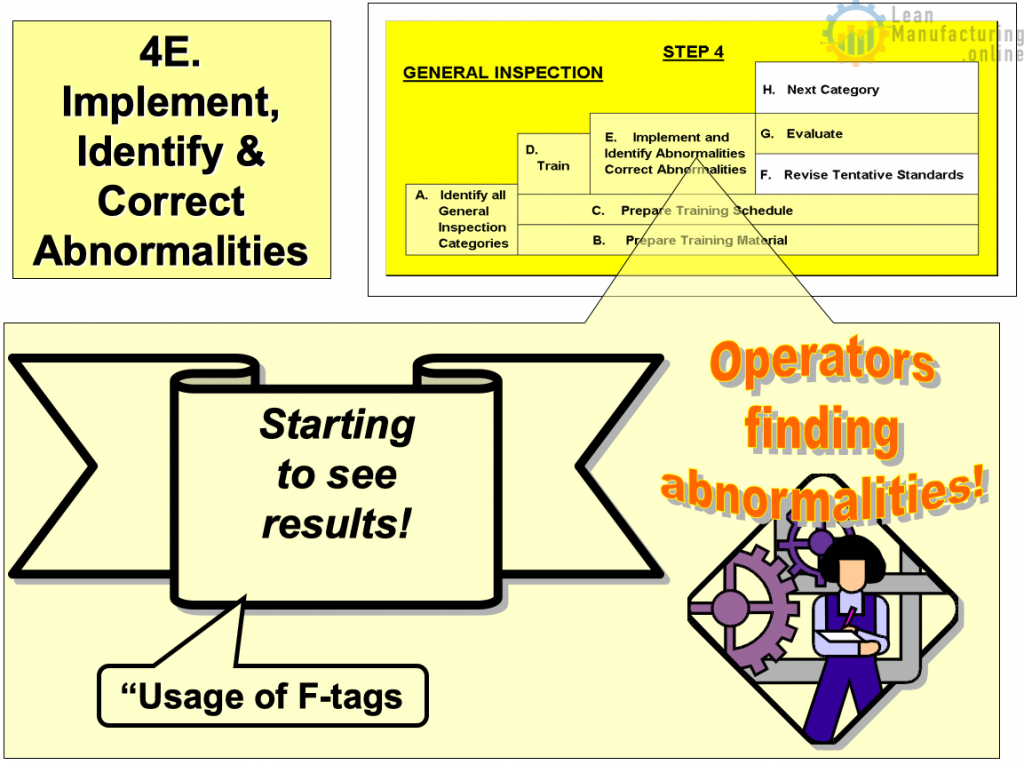

Implement, Identify & Correct Abnormalities