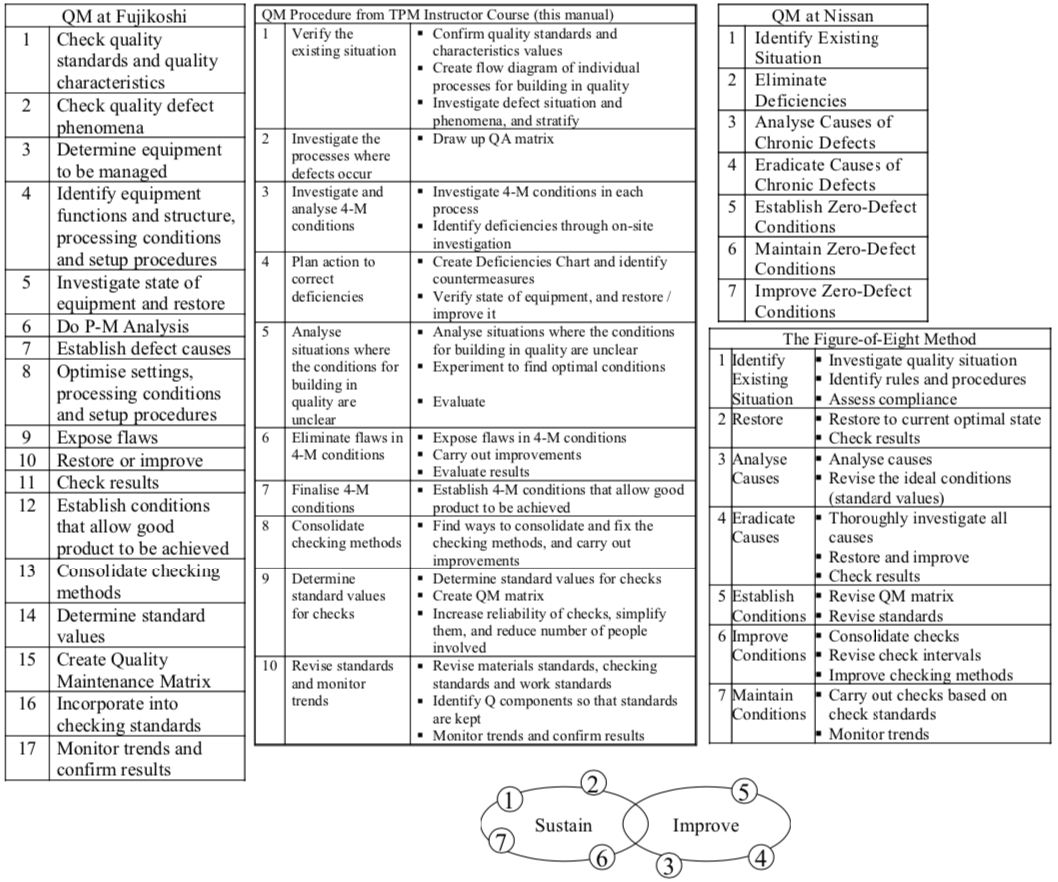

Many Japanese companies started building Quality Maintenance systems in the early 1980s. As these companies strove to improve the quality of their products through Quality Maintenance, they came to see that it consists of two principal activities, quality sustainment and quality improvement. By the mid-1990s, a large number of them had arrived at an approach consisting of the following seven steps:

- Identify Existing Situation

- Eliminate deficiencies

- Analyze Causes

- Eradicate Causes

- Establish Conditions

- Improve Conditions

- Maintain Conditions

The Figure-of-Eight method aims to establish a system that builds in quality from the twin perspectives of sustainment and improvement through the process. It should, therefore, only be started after the 10-step Quality Maintenance procedure has been completed at least once. The Figure-of-Eight Method includes the QM matrix but not the QA matrix because it assumes the latter has already been compiled.