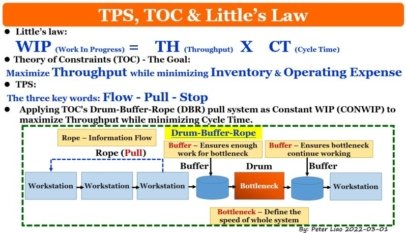

The Toyota Production System (TPS) is a production system created by Toyota Motor Corporation to build a production system without waste.

To minimize seven wastes (overproduction, waiting time, transportation, processing, inventory, movement, defects), we will use just-in-time, kanban, levelling, andon, why-why five times. Many methodologies, such as automatization of jidoka, one-piece flow, etc., will be thoroughly implemented.

However, it is said that the essence is a “consciousness revolution.” It is said that it lies in ”visualizing” the problem and improving it daily.

Toyota production system method

In the Toyota Production System, “Jidoka” is adopted instead of “Automation.” Automation with human intervention = (equals) Jidoka.

Modern production lines have made remarkable progress in mechanization, and each work process has been automated.

Therefore, when an abnormality occurs in the TPS, the production line is stopped temporarily to investigate the cause.

When the machine automatically detects an abnormality, it quickly notifies the person in charge of managing the production line of the content of the abnormality.

The production line is stopped at this time. After that, the production line manager will investigate the cause.

Such improvement activities can reduce the occurrence of defective products and improve quality. In other words, Jidoka refers to a system that builds a system that does not produce defective products, which is a significant waste of production.

In addition, the Toyota Production System adopts a just-in-time production system that produces only what is needed and in the amount required.

In addition to thoroughly eliminating waste related to production, it is possible to reduce deterioration in product quality and variation in finished products. Large waste and loss will occur if work is delayed due to a shortage of what is necessary for production. Conversely, if the production volume is large, there is a possibility of waste in management costs.

The “Kanban method” is adopted to make Just-In-Time successful

It is a well-known story that the kanban system was based on the product replenishment method of supermarkets that Taiichi Ohno saw during an inspection tour of the production technology of an American automobile company. From this fact, we can see that from the beginning; just-in-time was not a production technology but a “connecting technology” between operations, that is, logistics. Just-in-time is cash flow management that speeds up the conversion to cash by making it quickly after receiving an order. The Kanban system is a system that uses work instructions that describe the time and quantity of parts to be delivered. This method makes it possible to produce products as planned without waste, and production efficiency can be significantly improved.

Advantages and disadvantages of the Toyota Production System

The advantage of the Toyota production system is that the production plan is decided when there is a request from the customer as a previous process, and the necessary amount of production is produced at the time.

This is a production method that minimizes inventory and reduces the possibility of wasteful management and wasteful production.

In addition, companies can secure profits by reducing costs, but by adopting the Toyota Production System, it is possible to eliminate various wastes (cost reductions, management wastes, etc.) This makes it easier for companies to achieve cost reductions that are important to them.

A disadvantage of the Toyota Production System is that it is impossible to respond immediately when a customer requests a large amount of inventory in real-time.

In general production, inventory is secured to increase sales opportunities through mass production and reduce costs.

However, it is a high-risk production method because excess inventory tends to occur due to a decline in demand, and waste such as management costs such as production waste and inventory storage costs are likely to occur.

However, it is possible to meet the “request for real-time mass inventory,” which is a disadvantage of the Toyota Production System, so it is necessary to select what kind of production system to introduce depending on the situation.