AM – Step 6 Activities – Standardization

- Objective

- Standardize Routine Operation to sustain & prevent Problems.

- Activities

- Develop Sub-step Activities

- 6.1 Quality

- 6.2 Change Over

- 6.3 Cyclic Operation

- 6.4 Safety

- Develop Sub-step Activities

- Review the Role of Operators, and Efficiency Improvement and Standardization of Related Work

- Maintain an Effective Autonomous Inspection System

AM – Step 7 Activities – Autonomous Management

- Objective

- Establish Line Management system by First line Team – Autonomous Management

- Control Cost – develop Annual Budget by Team

- Use “Policy Deployment – “Hoshin Kanri”

- Maintain Optimal Equipment Condition

- Striving to Meet the Targets of Zero Failures and Zero Defects

- Maintaining a Proactive Attitude To Equipment Maintenance

12 Key Points in A.M. Implementation

- Collaboration between departments is important

- Thoroughly educating members during the introductory stage at each department, to ensure their understanding of what AM is;

- Sharing roles to attain common targets and exerting maximum efforts

- Leadership of Managers results in practice

- AM is work in itself;

- Placing emphasis on hands on experience, unconcerned with theory.

- The precedent of manager models represents the initiative

- The Managers initiative and shining example is an essential requirement;

- Understanding the essence of AM at the workshop through the use of actual equipment.

- The manner of diagnosis leads to activation

- Directing the people to the tasks to be done in the future;

- Evaluation of what has been done.

- Through education, it is understood that to teach is to learn

- Adopting new ideas for carrying out education;

- Understanding the necessary knowledge personally, to ensure subordinates’ understanding.

- Enhancing understanding through One Point Lessons

- Basic Knowledge: Info that must be shared;

- Problem Case: What was lacking and recurrence prevention;

- Improvement: Cases leading to positive results.

- The experience of success leads to a challenging mind-set

- Accumulating many successful cases;

- Experiencing what has not been carried out help us overcome difficulties.

- Giving Focused Improvement themes to teams for implementation

- Themes related to routine work;

- Minor stoppages, set-up, failure analysis.

- The TPM Activity Board is a communication tool between the Manager and the team members

- Showing the participants plans, ways of thinking, status of execution, and achievements in an immediately understandable way;

- The activity board allows Managers to get a sense of team members efforts.

- Meetings are a barometer of the activity level of the team

- Creating good ideas through all members participation and expression of their opinions;

- Forum of reflection, study, and proposal.

- Work should be executed promptly

- Delay in the execution of requested work will impede the activation of circles;

- Review of the maintenance sector’s response.

- Implement thoroughly

- The degree of thoroughness determines the quality of maintenance and management.

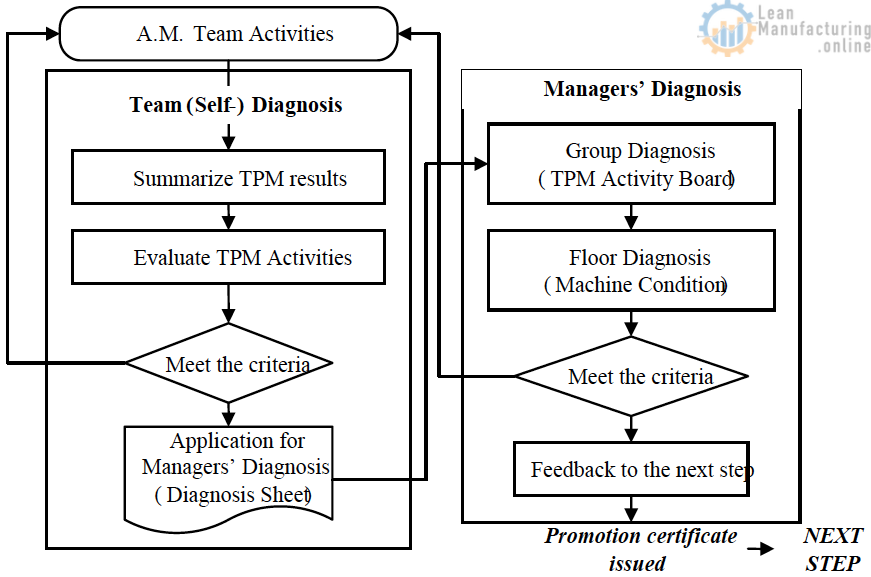

Step Diagnosis

This is the important goal-sharing process.

- Each team evaluates the progress of Kaizen/TPM.

- Control timeline (Deadline)

- Evaluate Kaizen/TPM activities from the viewpoints of “Need to Improve” – Weakness & Opportunity.

- Align the direction with the plant-wide master plan.

- Managers evaluate the progress of Kaizen/TPM form the viewpoints – how each team drive the right direction onto the plant-wide target & goals and managers’ target & goals.

- Plan & Analyze the resource for a team to move on the right direction & the right on time.

- Analyze the connection with AM and other pillars. – Move smoothly such as AM and T&E using F-Tags, … etc.

Step Diagnosis Flow

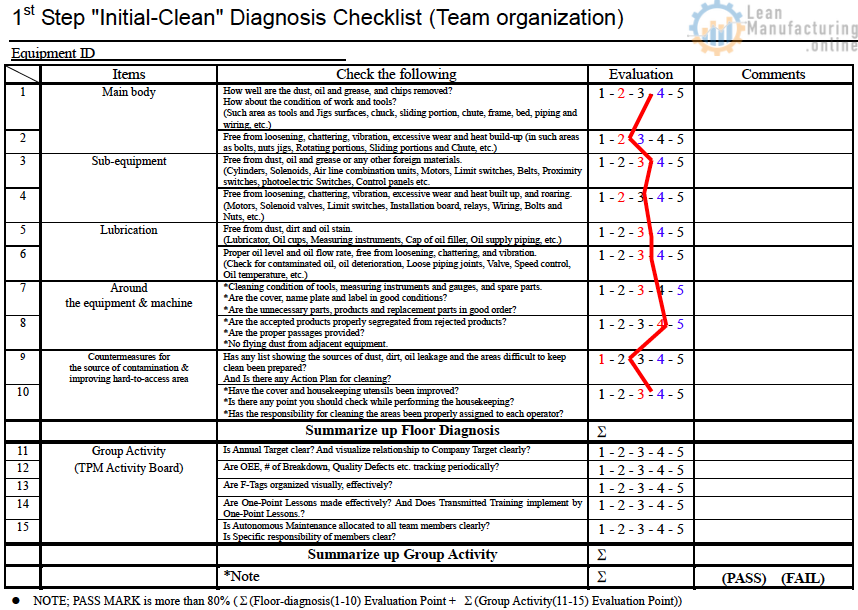

Step Diagnosis Checklist

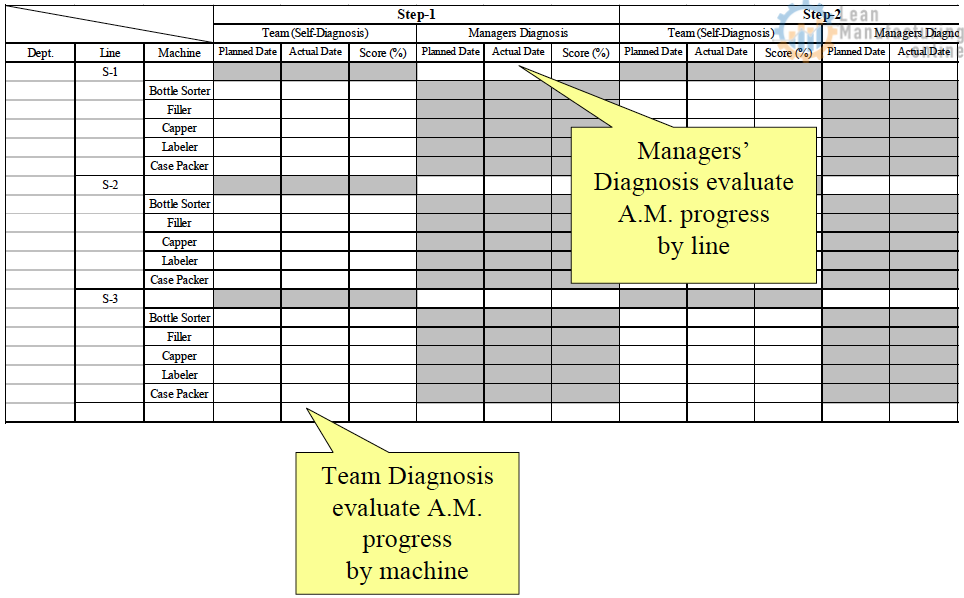

AM Step Progress Control

Elements of an Activity Board

TPM Activity Board Requirements (Activity Board for First-line Small Group)

- Policy & Implementation plan

- Policy & Target

- Company / Factory policy & target / Department / Team policy & target (Annual, quarterly) / Action plan; TPM Master plan (Plant-wide and long term) / Team implementation plan (Annual plan and Quarterly)

- Indicators (Measurables)

- Tracking data (Daily & Monthly)

- Productivity (Output per hour person)

- Quality (# of scrap and type of scrap)

- Cost (Overall Equipment Efficiency – Bottle neck machine)

- Delivery & Availability – Zero Breakdown calendar

- (On-time delivery ratio, # of unscheduled breakdown, downtime, change over time

- Safety (Lost time injury)

- Data collection (Daily or Every shift)

- # of Major stops (Equipment Failures)

- # of scrap and type of scrap, rework

- Safety Information (# of Near Miss Report, LTA / MA)

- * Change over time , Time and Operation Analysis Chart

- # of minor stoppage

- Tracking data (Daily & Monthly)

- AM & FI Activities Process

- AM Activities at each step – SOCS &HTA, Visual Control

- One Point Lesson (Basic knowledge / Improvement case / Troubleshooting)

- Trend chart – # of F-Tag (Blue / Red ) & F-Tag log (Fuguai list)

- FI Topics Register – 5-why analysis / P-M Analysis

- Autonomous Maintenance standards

- Review of action taken

- # of One-point lesson / # of Tag (Blue / Red)

- Step Diagnosis comment, score & sticker