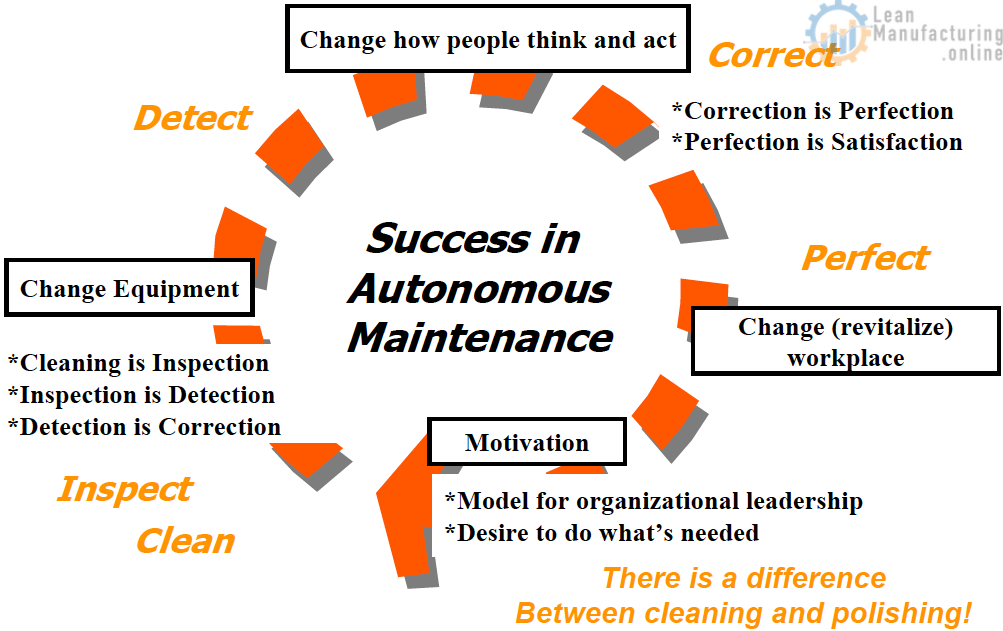

What is Autonomous Maintenance?

- Shop-floor based activities

- Operator conducted

- Operator enhancing

- Team activity

- Shop-floor Kaizen & TPM Foundation

- Part of the job!

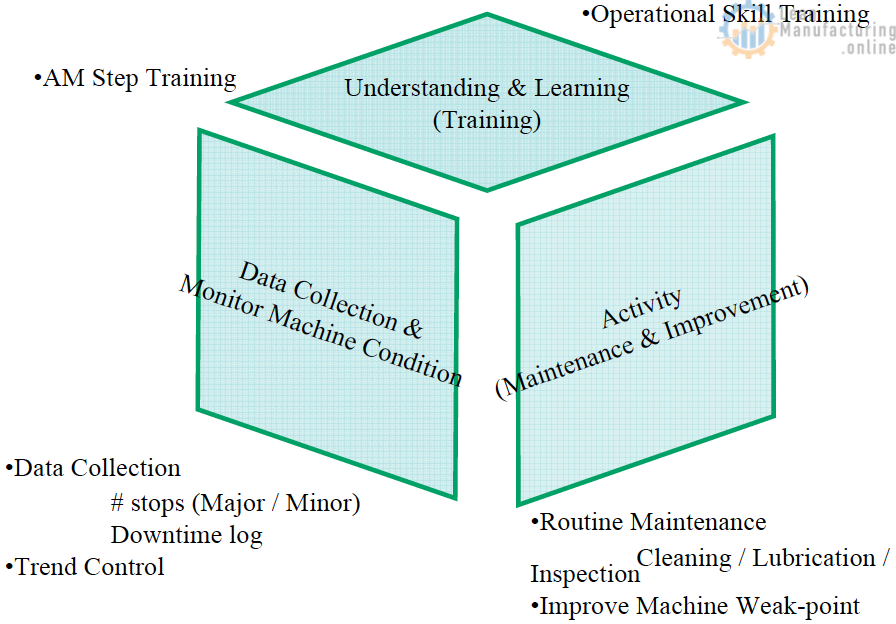

Concept of Productive Maintenance

Phases in Autonomous Maintenance

Why Autonomous Maintenance?

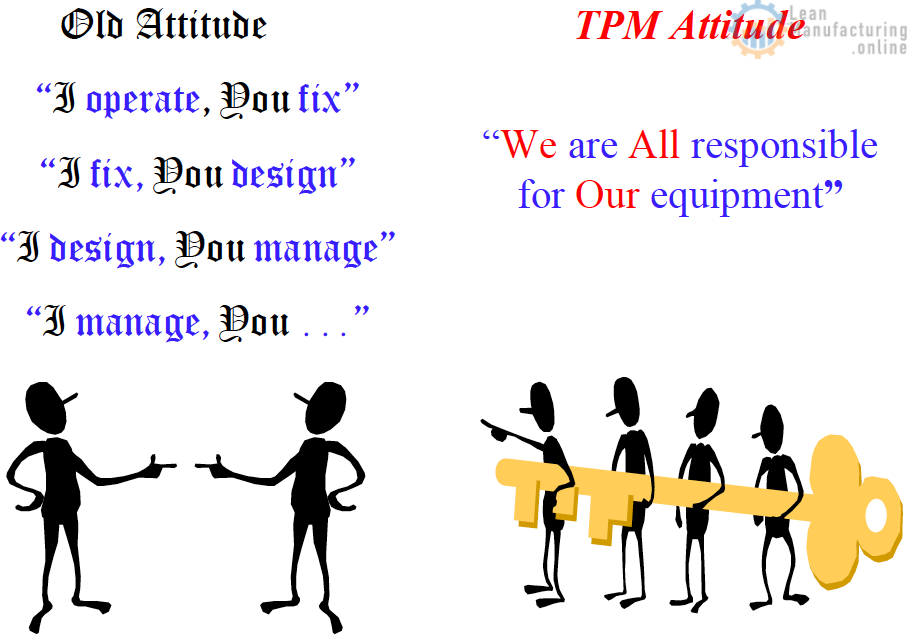

Basic Concept of Autonomous Maintenance

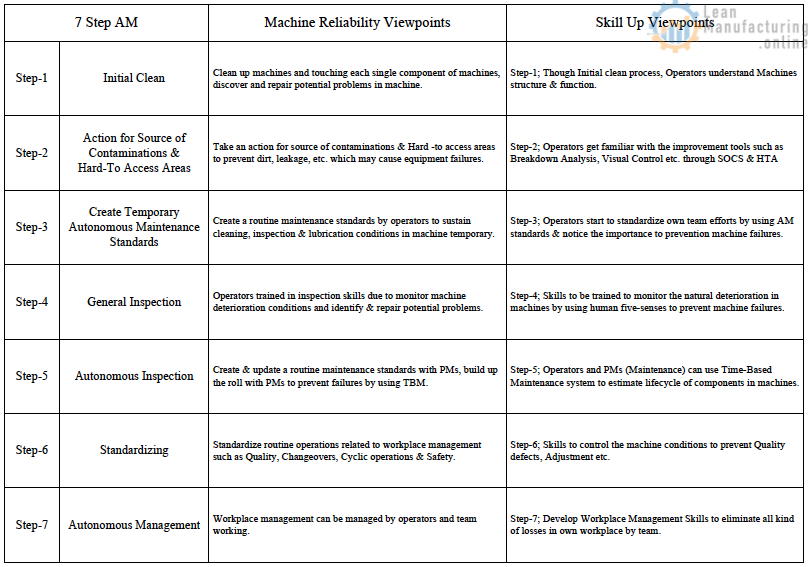

7 Step Autonomous Maintenance

Autonomous Maintenance is the activities designed to restore and maintain equipment to optimal condition.

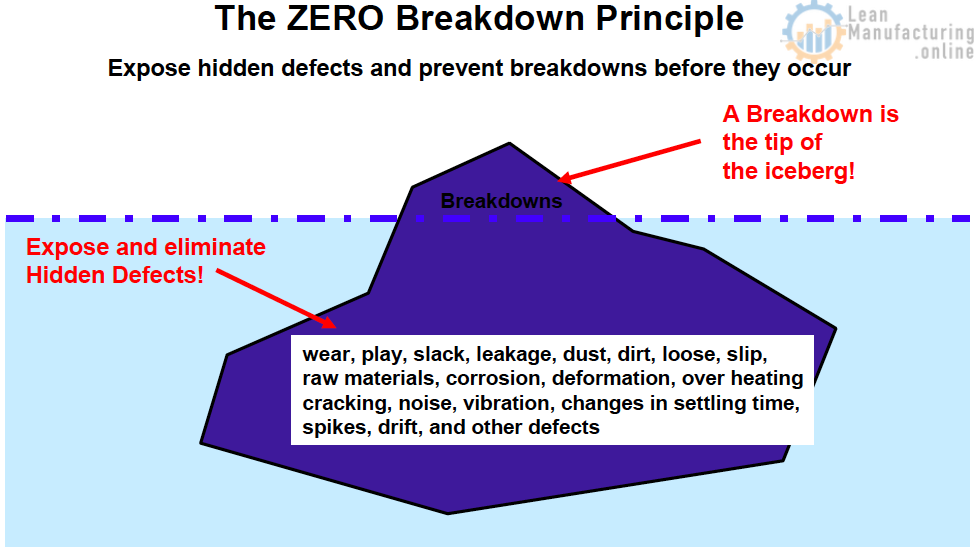

Zero Breakdown Approach

What to look for! – Forced Deterioration

Safety Comes First!!!

- Make sure team members use lock-out and tag-out (LOTO)

- Identify any potential safety issues

- Use proper PPE

- Use the right tools and the tools right!

- No part of the job is worth losing life or limb