When equipment breaks down it is necessary to find root cause of the problem. Let’s review five main causes.

Forced Deterioration

These breakdowns are caused by:

- Lack of Cleaning (accumulation of Dirt and Dust);

- Lack of Inspection (e.g. loose nuts, bolts, etc);

- Lack of Lubrication.

Lack of Basic Conditions (CIL) !

What will happen…

- if you never clean your stove?

- if you never check the air in your car’s tires?

- if you don’t change the oil in your car for 100,000 miles?

Example:

Forced Deterioration – Countermeasures

- Cleaning Standards – ensure parts are clean and SOCs are removed;

- Inspection & Visual Control – ensure nuts and bolts are in the right place;

- Lubrication Standards – ensure parts are well-oiled and running smoothly.

Natural Deterioration

These breakdowns are caused by:

- Friction and contact between parts;

- Friction between parts and the environment.

Every Mechanical Part has a limited life-span, therefore even under basic conditions (CIL) natural deterioration will occur.

What will happen…

- if you never change the brakes of your car?

- if you use the same shoe everyday for 2 years?

- after water flows in a pipe for 100 years?

Natural Deterioration – Countermeasures

- Time Based Maintenance (TBM)

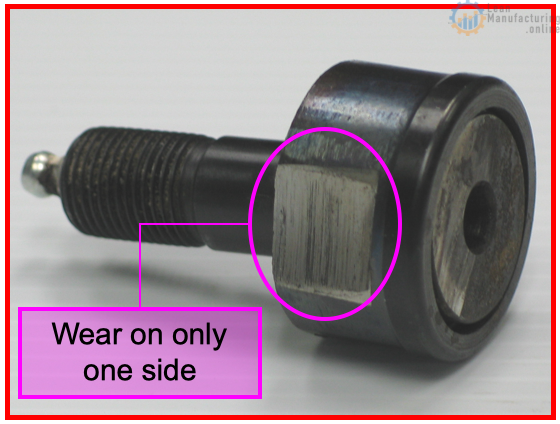

Weak Point Part

Breakdowns caused by components that were not correctly designed to support their function. Component can suffer:

- Overload

- Over heating

- Corrosion

- Accelerated wear

It’s the same as:

- A chair breaking repeatedly, even if you keep replacing it;

- The brake in your car failing repeatedly despite maintenance.

Weak Point Part – Countermeasures

- Redesign component

Out of Operating Condition

These breakdowns are caused by:

- Equipment being ran out of specified conditions. Specified conditions might be:

- Temperature

- Speed

- Air Pressure

What will happen if you…

- Plug your 110V hair dryer in a 220V receptacle

- Dry your cat in the microwave

- Drive an Indy Car in the city

Example:

Out of Operating Conditions – Countermeasures

- One Point Lessons

- Visual Controls

- Match Marks

Lack of Knowledge

- Breakdowns related to lack of knowledge of:

- Machine operation

- Machine repair

- Installation

It’s the same as:

- YOU driving a Nascar car during a race TODAY!

- You needing to pilot a jet flight

Lack of Knowledge – Countermeasures

- One Point Lessons

- Training

- Maintenance Standards