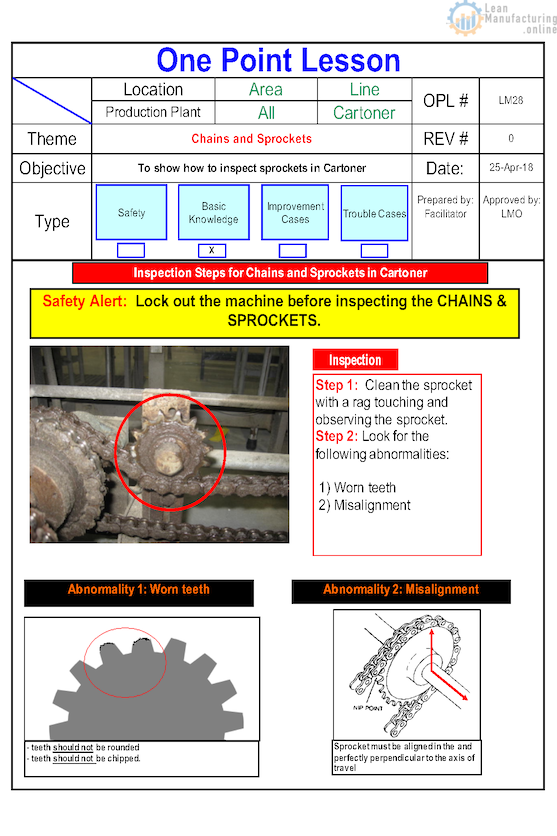

Step 1: Clean the sprocket with a rag touching and observing the sprocket.

Step 2: Look for the following abnormalities:

- Worn teeth

- Misalignment

Abnormality 1: Worn teeth

- teeth should not be rounded,

- teeth should not be chipped.

Abnormality 2: Misalignment

The sprocket must be aligned and perfectly perpendicular to the axis of travel.

January 31, 2026

0 1,146

Six Sigma vs Lean Six Sigma: A Practical Guide

December 27, 2025

0 2,193

How to Improve Manufacturing Processes with the RIVET Method

Artificial Intelligence

Continuous Improvement

Lean

Lean Manufacturing

Lean Six Sigma

Productivity

Safety

TPM

World Class Manufacturing

November 19, 2025

0 2,368

Gemba Walk GPT: The Smartest Way to Turn Observations Into Real Improvement

November 16, 2025

0 2,696

How to Create a Step-by-Step Reveal Animation in PowerPoint

Book reviews

Continuous Improvement

Leadership and Continuous Improvement

Lean Manufacturing

Lean Six Sigma

October 4, 2025

0 3,880

Explore the Best Free Online Libraries in 2025

October 3, 2025

0 3,729

TPM Master Plan: The Roadmap to World-Class Manufacturing

5S

Autonomous Maintenance

Early Equipment Management

Education and Training

Focused Improvement

Manufacturing Support

Planned Maintenance

Quality

Safety, Health and Environment

TPM

World Class Manufacturing

January 31, 2023

0 6,868

TPM Pillar Self Assessment

April 12, 2022

0 7,454

Detailed Autonomous Maintenance (AM) Master Plan. Steps 1 – 5

5S

Autonomous Maintenance

Early Equipment Management

Education and Training

Manufacturing Support

Planned Maintenance

Quality

Safety, Health and Environment

World Class Manufacturing

March 1, 2022

0 2,060

Example of Food Manufacturing site review

Autonomous Maintenance

Focused Improvement

Planned Maintenance

Quality

Safety, Health and Environment

TPM

TPM Introduction

Training

World Class Manufacturing

February 15, 2022

0 6,957

The 3 Tools of TPM

December 25, 2021

0 2,063

How to improve the support for Autonomous Maintenance (AM) teams

Most Popular

4M Analysis Process

The purpose of this procedure is to define the steps to do a 4M …

I really love this website, it seems like a treasure to me. Cos it’s what I have been searching up to now. Your instruction is very detailed and practical. I dont know who the web owner but I think he must be a TPM guru^^

Thanks for your feedback, let us know if you either have any questions or require guidance through TPM journey.

Dear Mr. LEANTPM6S,

You are very kind to suggest my questions, actually, I just wait 4 that^^. I really wish you also recommend some top-notch apps/softwares/websites being used for each TPM/WCM pillars. For example, I use Proeye software to analyze working motions to detect wastes and losses, Matlab web to model and analyze variations. But I also know what I know today could be out-of-date right after the other day. So, I think It will be a great share when u also recommend some great ones.

Ariel,

Thanks again for your feedback and questions. ProcessMA is an Excel add-in that will help you to better utilize Six Sigma tools. It’s available as a 30-day free trial on developer’s website and if you will find it useful, license can be purchased there.

Love this site!

I am just searching the TPM implementation documents with practical approach.

Each one of your documents catch my eyes to read it.

Very Practical & very detailed.. Thank a lot to you http://leanmanufacturing.online/