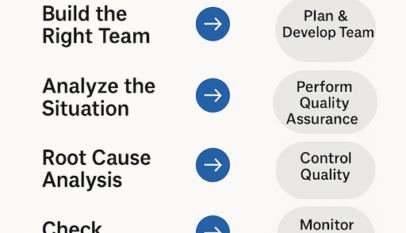

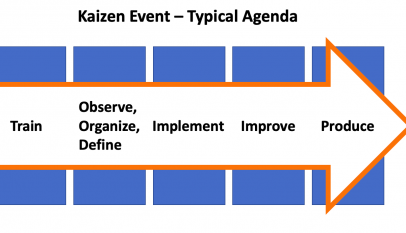

There are many tools and processes that the Manufacturing Plant uses to reduce losses. Today, we will describe the 12-step kaizen process:

📉 Identify Losses

📋 Selection and justification of the subject

🏫 Understand the process and equipment

🕐 Grasp the actual situation

✔️ Establish objectives

☝️Make a plan

❓Cause analysis

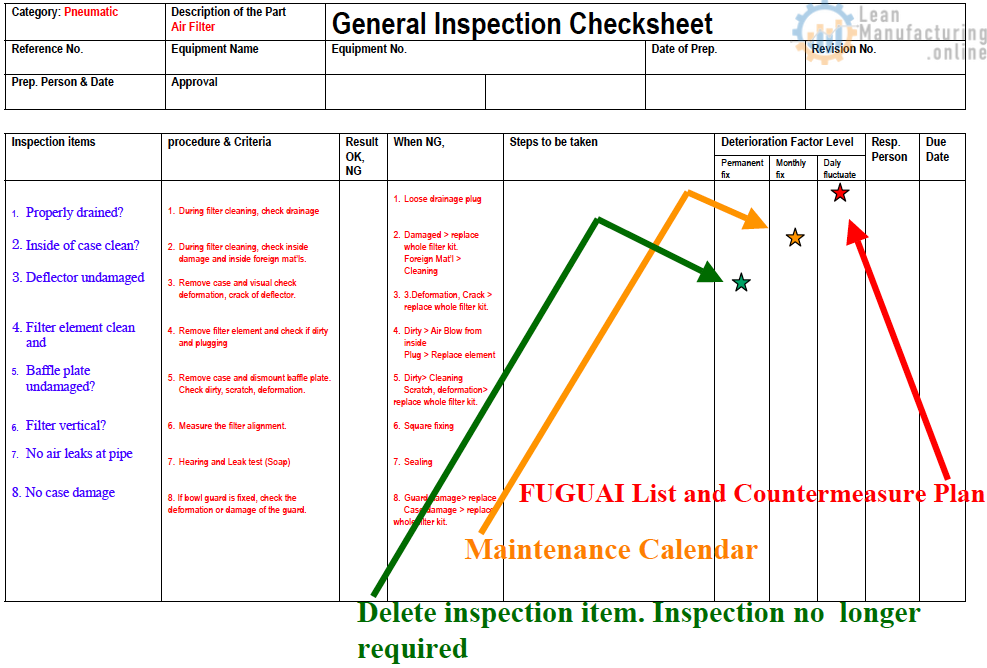

⚙️ Propose countermeasures

🛠️ Carry out countermeasures

✅ Verify the results

📏 Standardization

🔮 Future Plans

To see the full process, visit 12 Step Kaizen Story.

Right on point!