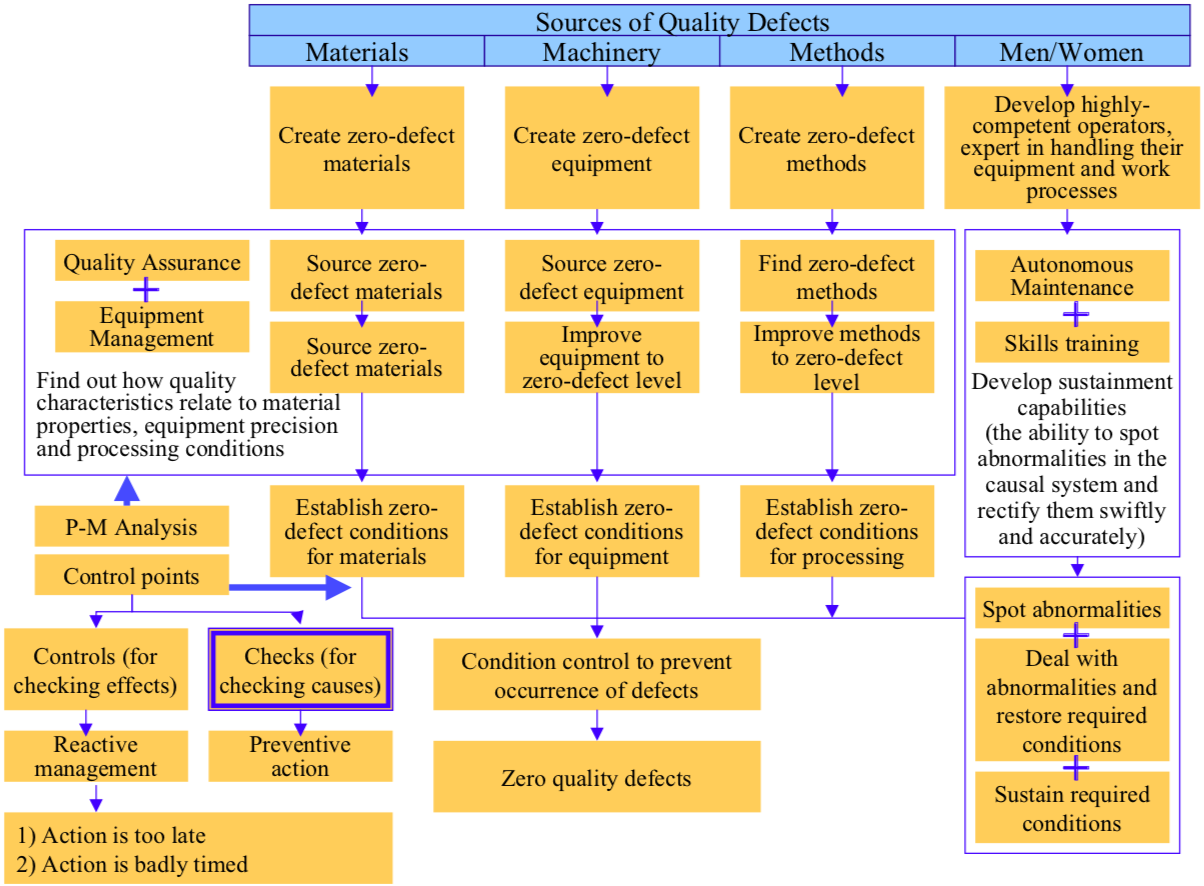

To prevent quality defects due to equipment or process conditions, we must establish the conditions under which the equipment or process will not produce any defects. To do this, we must fully coordinate our quality assurance activities and equipment management activities and identify how the product’s quality characteristics are affected by materials, methods and equipment precision.

Establishing zero-defect conditions involves identifying the same group of causes behind any possible defects and then setting ranges for the material conditions, method conditions and equipment precision to ensure 100% good product. The central philosophy of Quality Maintenance is to sustain and control the established requirements and consequently achieve zero defects. This approach relies on having fully conversant operators with their equipment and has been trained in Autonomous Maintenance and other relevant skills (see Figure “The Basic Approach to Quality Maintenance”).

Achieving perfect quality requires a significant shift in attitude – from the conventional approach, where defects are only discovered when the product is inspected and action taken after the event, to a process in which each condition affecting quality is measured periodically. Preventive action is taken before that condition exceeds its permitted range.

The next posts are looking at how to establish, standardize and improve zero-defect conditions for materials, machinery and methods.