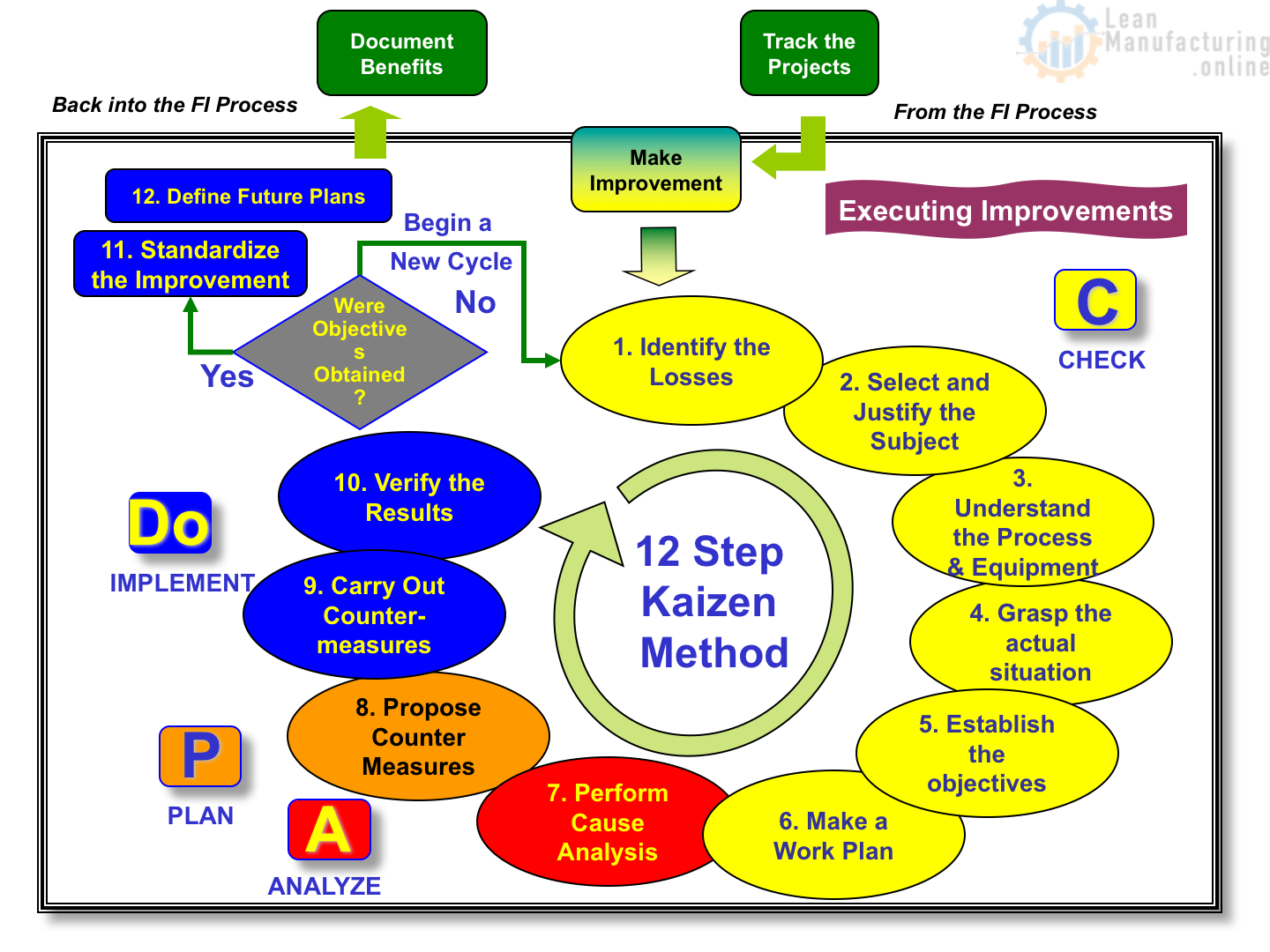

The Key Tool for Executing Focused Improvement

- Check – Observe, Collect Data

- Analyze – Determine Root Cause

- Plan – Formulate Actions

- Do

- Implement Plan

- REVIEW – Monitor results and return to Check

Cap-Do form can be found here.

CAP-Do: The Check Phase

- Identify the Problem

- “A state of difficulty that needs to be resolved”

- “A question raised for consideration or solution”

- Understand the Ideal Situation

- Identify the Phenomenon

- “Whatever, in matter or spirit, is comprehended by observation”

- “Any state or process is known through the senses rather than by intuition or reasoning”

Phenomenon Means:

- Observing the facts with our own

eyes & all senses - The facts without presumption

CAP-Do: Check Step 1

- Identify the Problem

- “A state of difficulty that needs to be resolved”

- “A question raised for consideration or solution”

- Understand the Ideal Situation

- Identify the Phenomenon

Check Step 1: Identify the Problem

- Collect Data

- Go to the “actual place”

- Observe

- Take Photographs / Videos

- Interview

- Collect Data*

- Assemble all available related data from Loss Tree Analysis

CAP-Do: Check Step 2 Understand the Ideal Situation

Machine

- Equipment Sketches

- Operational principles & model

Material

- Material samples

Man & Method

- Flow charts of the process

- Forms and procedures

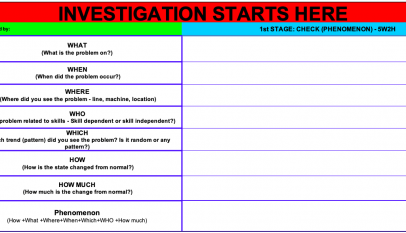

Check Step 3: Identify the Phenomenon

5W’s 1H* (Define the problem, show loss data)

- What, When, Where, Who, Which, and How.

- Requires information collected in CHECK Steps 1 & 2 to complete the 5W1H form and identify the “phenomenon”.

- If there is not enough data from CHECK Steps 1&2, the 5W1H must be paused to get the data.

- The cause is NOT assigned/implied in the Phenomenon statement.

What:

- What thing or product did you see the problem?

When:

- When did the problem occur?

Where:

- Where did you see the problem? (Line/Machine/Location)

- Where on the work or material did you see the problem?

Who:

- Is the problem related to skill? (Skill dependant or independent)

Which:

- Which trend (pattern) did you see the problem have?

- Is the trend random or is there a pattern?

How:

- How is the state different from a normal condition?

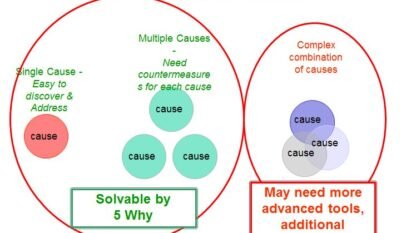

CAP-Do: The Analyze Phase

- Determine Root Cause

- 5 Why (Why-Why)

- Principle of Operation

- SEND Analysis

- Formulate Possible Actions

CAP-Do: The Plan Phase

- Review and Prioritize Possible Actions

- Short and Long Term Actions

- Assemble Required Materials

- Write OPL’s

- Schedule Work

- Create OPLs

CAP-Do: The Do Phase

- Safety Comes First

- Implement Actions

- Review

- Observe Results

- Hold the Gains

- Return to Check

CAP – Do Activity Board Content