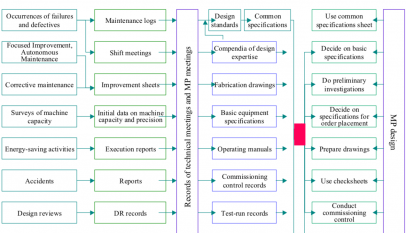

Once the equipment investment plan has been approved, it is time to decide on the equipment design and fabrication specifications, based on the investment proposal comparison table drawn up in Step 1. When this has been done, the second design review should be used to check that none of the items in the equipment design and fabrication specifications has been overlooked. The design and fabrication specifications should then be incorporated into the equipment concept, improving the precision of the design (see Figure “Detailed Flow Diagram of Action Plan”).

The analyses used in the action plan can be described as follows:

- Process Diagram This clarifies the sequence and limits of each process.

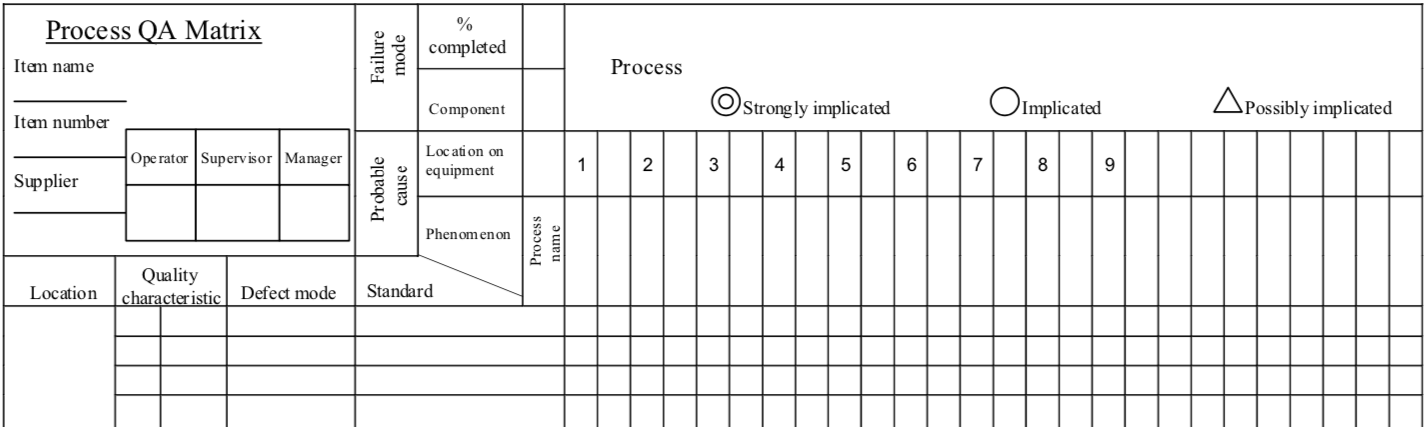

- Process QA matrix This clarifies the relationships between product quality and process. Figure “Process QA Matrix” shows a typical QA Matrix.

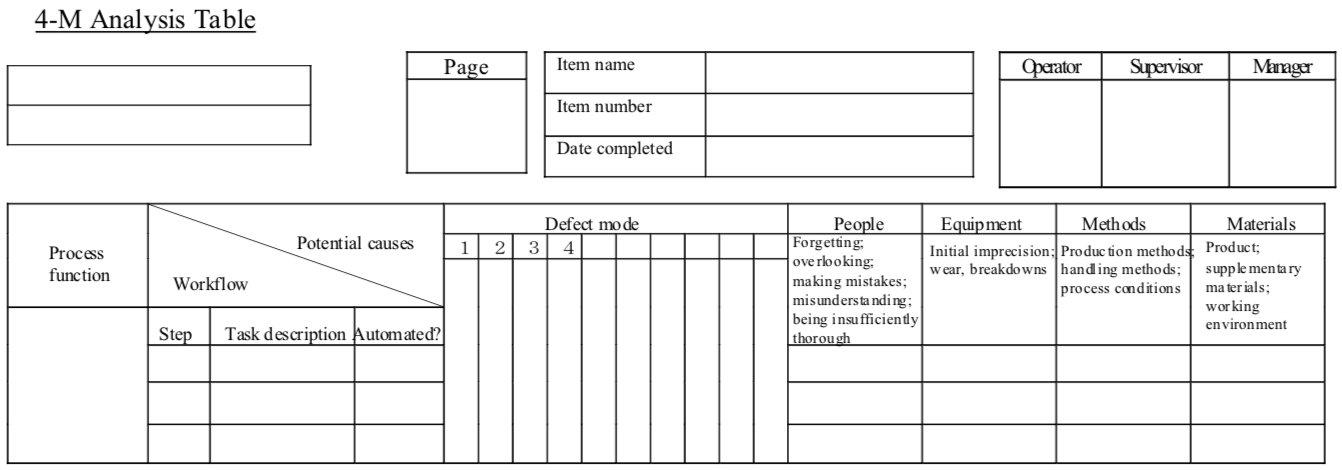

- 4-M Analysis The Process QA Matrix may show that certain processes are heavily implicated in the generation of defectives. In this case, the 4-M Analysis will show how these defects relate to the 4 Ms, and will clarify the equipment conditions needed to stop them from being produced. Figure “4-M Analysis” shows a typical 4-M Analysis.

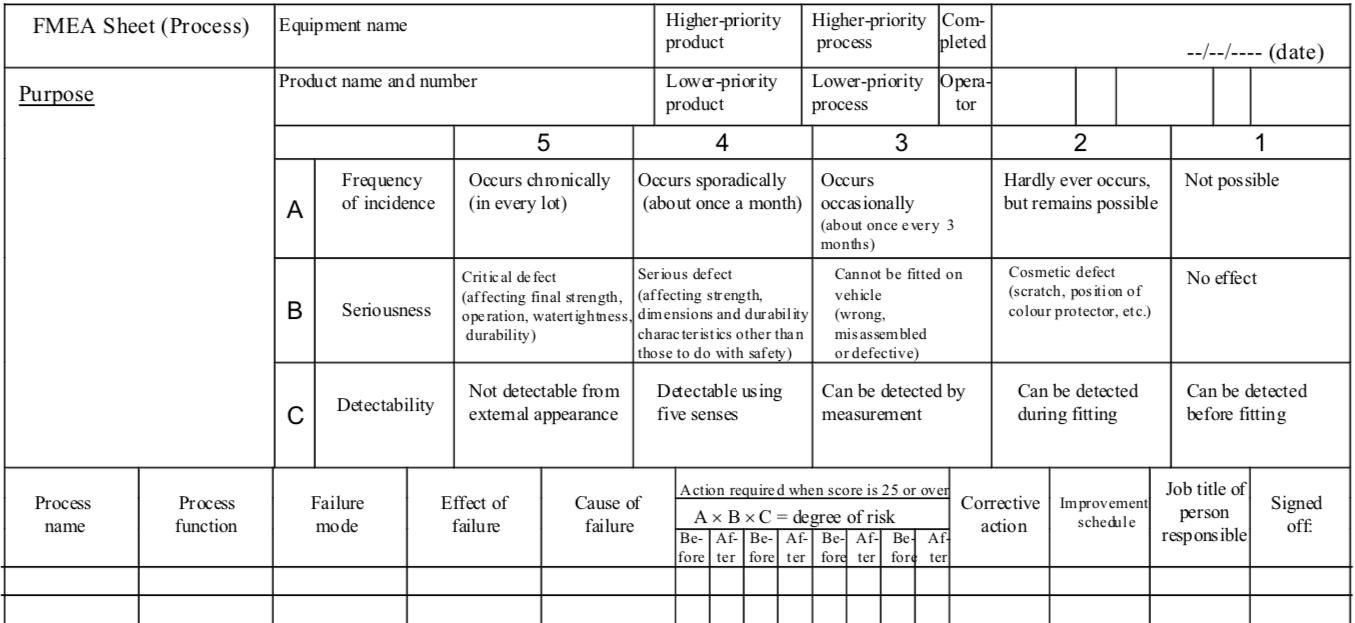

- Process FMEA The Process FMEA further quantifies the degree of risk posed by the problems identified in the 4-M Analysis. This information is very useful in evaluating the equipment concept. If any item fails to meet the assessment criteria, the issue should be addressed, and a re-evaluation carried out. Figure “Process FMEA” shows a typical Process FMEA.

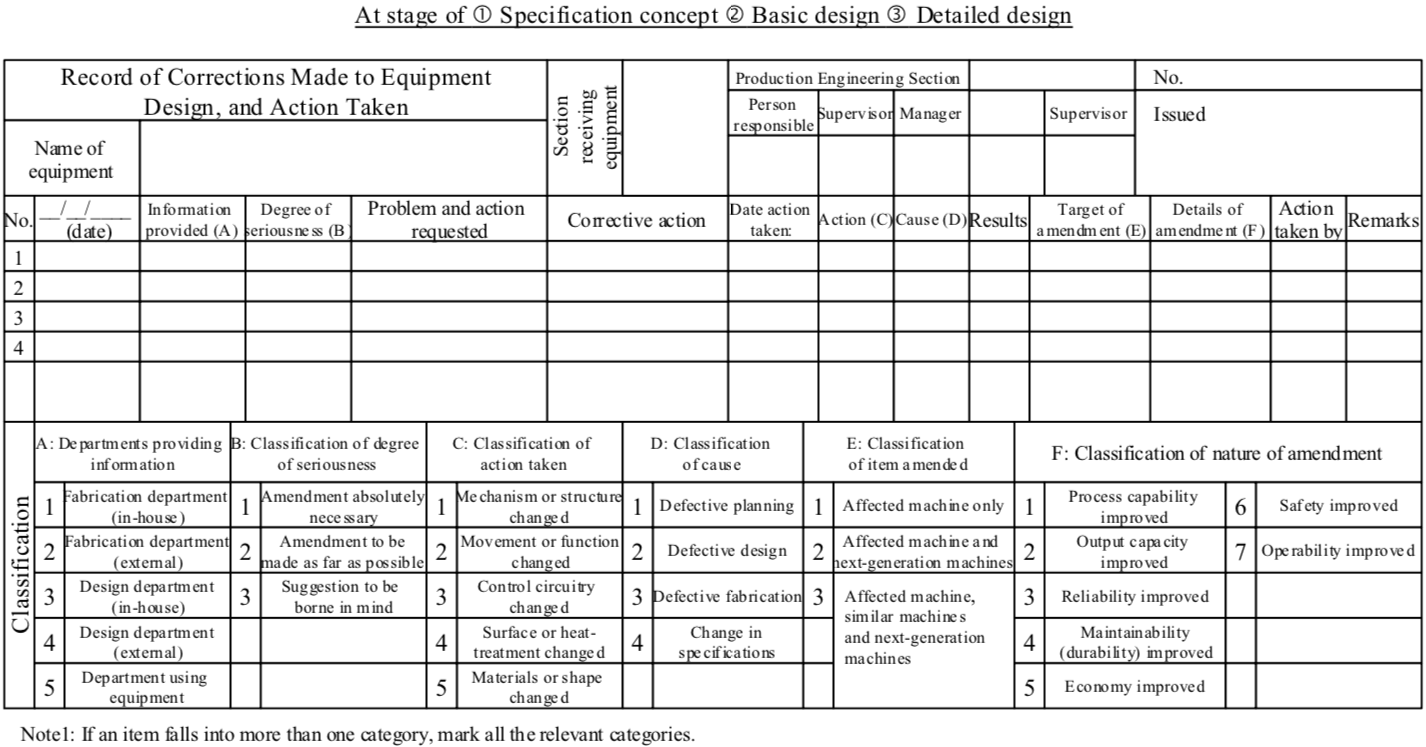

- Record of Corrections Made to the Equipment Design, and Action Taken Problems thrown up by assessing the equipment specification concept and carrying out the second design review should be carefully addressed in the equipment design specifications, using a form of the type shown in Figure “Record of Corrections Made to Equipment Design, and Action Taken”.