What is Maintenance?

Maintenance: It is a set of developed, organized and administered activities with the aim to economically viable ensure the operational status of a specific system.

The 7 steps concept of Autonomous Maintenance (operators) are similar to 7 steps of Planned (Effective) Maintenance (trades): “the left and right hand working together”

Breakdown/Failure definition

Breakdown/Failure means: Loss of the equipment defined function. Unscheduled stop of the equipment, performing loss of function, for over 10 minutes, with or without parts replacement.

Breakdown=With parts replacement,

Failure=Without parts replacement.

Why and What advantages in Recording the Breakdown/Failure?

- Ensures the team knowledge in relation to the breakdown and failure: When the breakdown occurred, What happened, where it happened and what was done to solve the problem. The breakdown record is also used as input into the Breakdown Analysis (BDA).

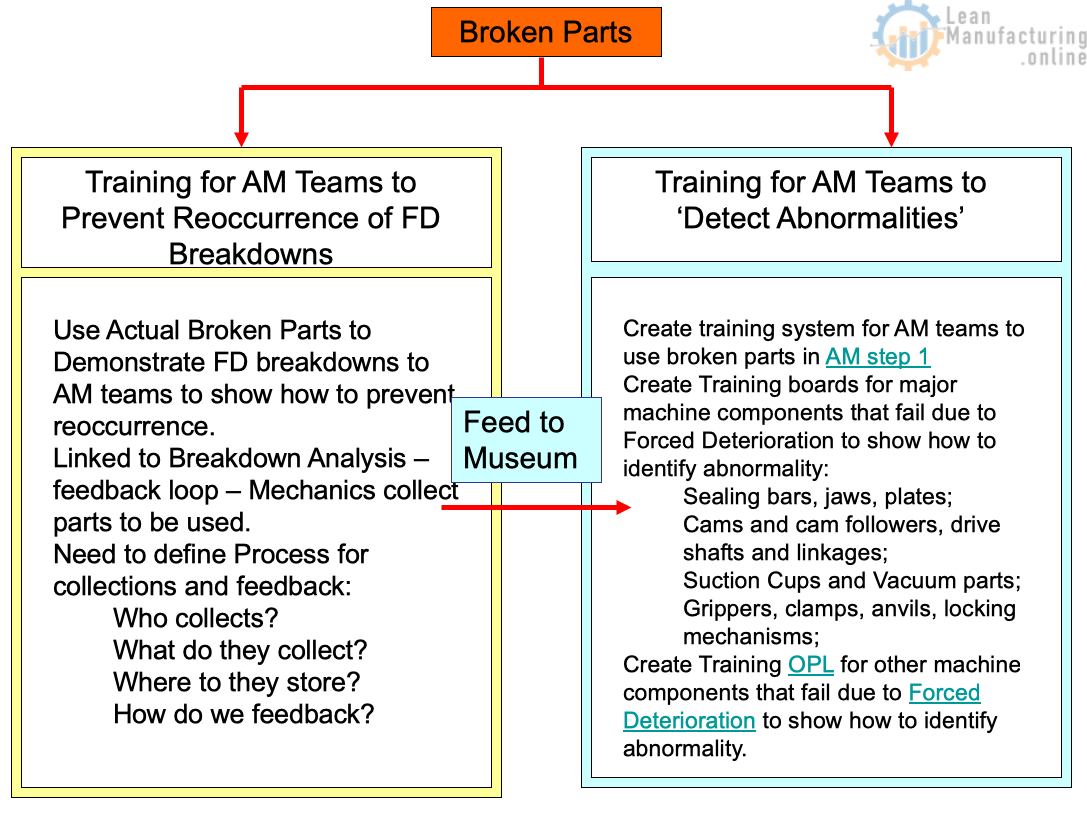

- This information can also be used to identify topics for training during the fourth stage of AM when the systems are prioritized by the type of breakdown/failures which happen more often;

- Allows the team to get to the root cause(s) to reduce to zero breakdowns/Failures;

- Allows to figure out if the cause(s) of the problem has a relation with the Man Method, Machine or materials so all contributing factors can be identified and appropriate countermeasures applied;

- Allows over time to evaluate the effectiveness of our maintenance activities and help determine if we need to modify our current preventive plan;

- Allows to set the training priorities in the fourth AM stage, when the systems are prioritized by the quantity of breakdowns/failures which happen more often.

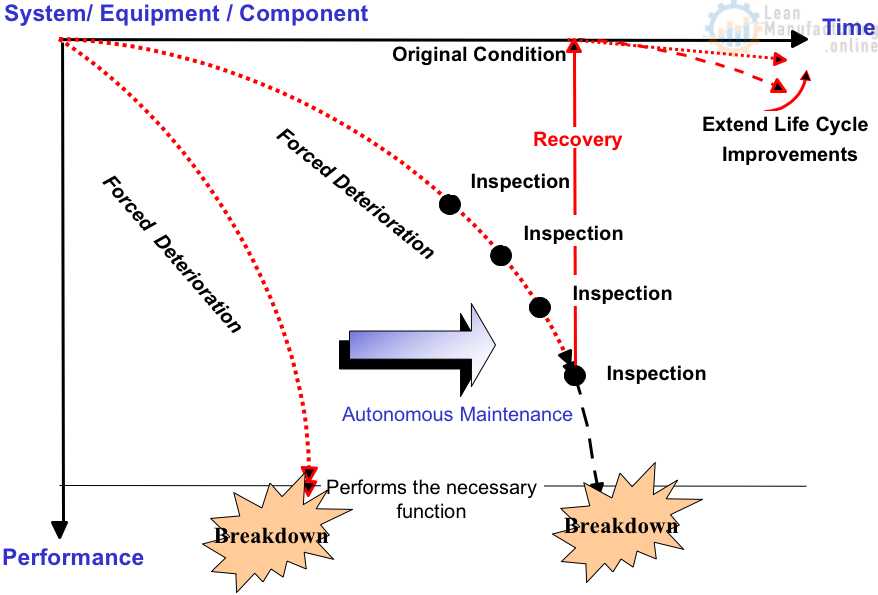

How the Breakdown Happens…

“ The equipment does not break by itself, it is broken by the man”

ZERO BREAKDOWNS

Why Do breakdowns happen?

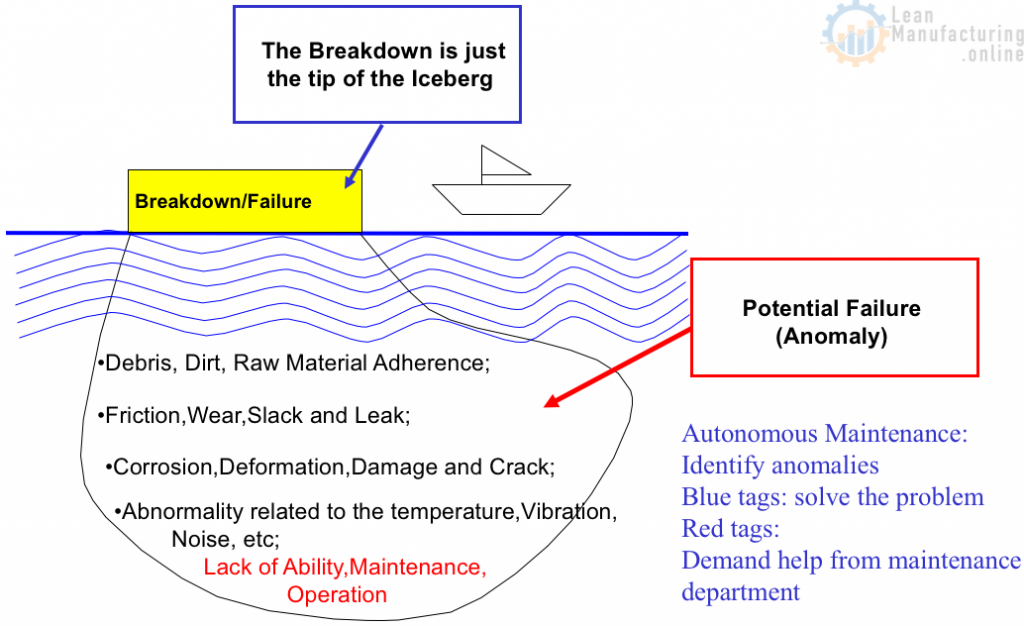

Breakdowns Iceberg/Failure

Notify Potential Failure is to prevent occurrence of Breakdowns/Failures

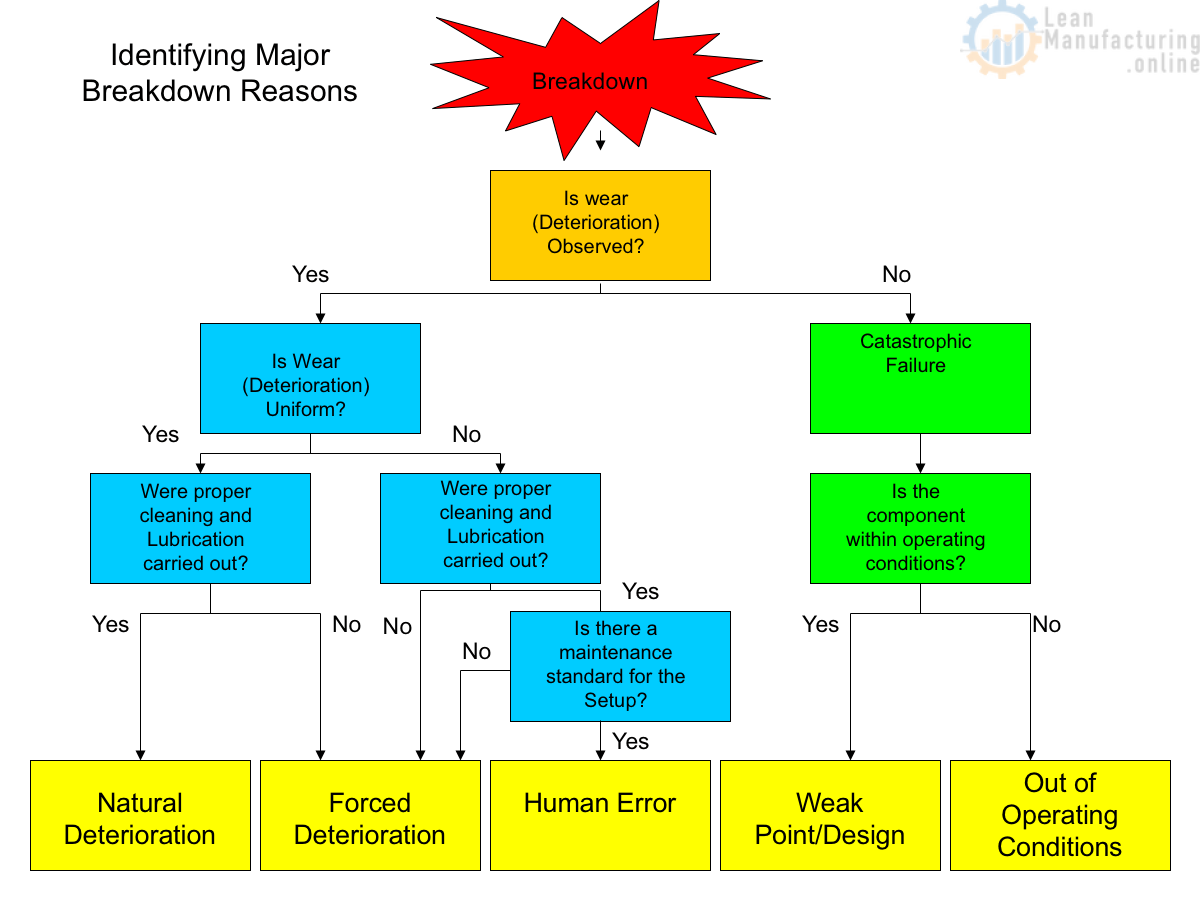

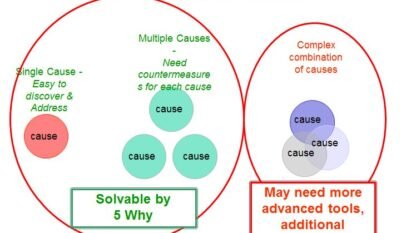

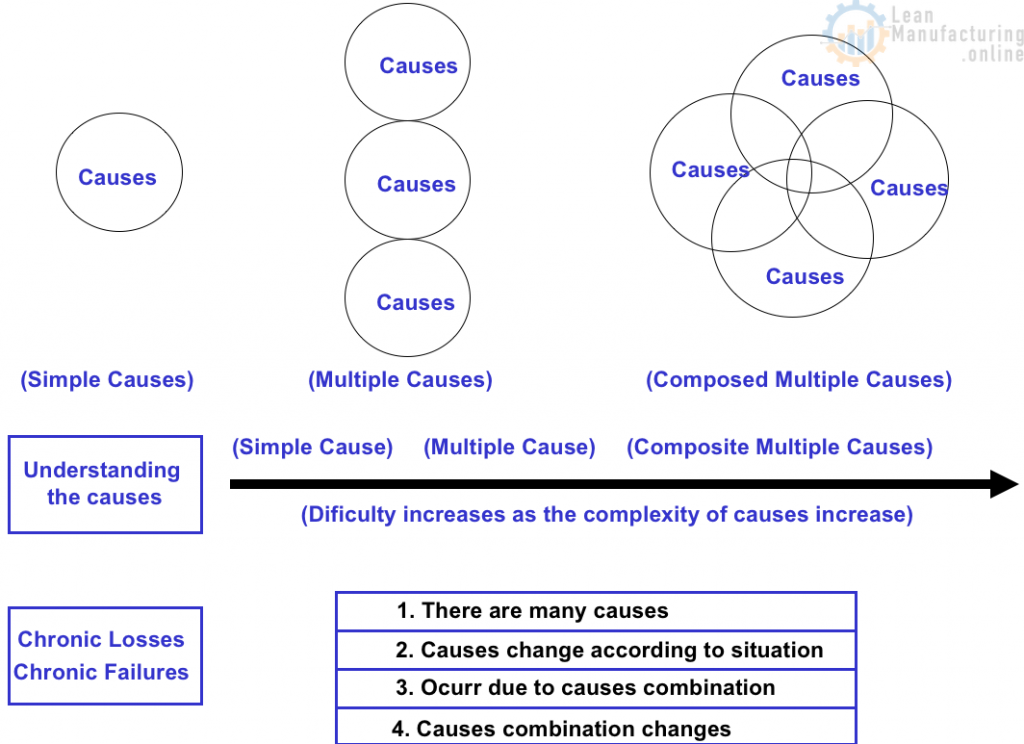

Causes Structure of Chronic Loss

Typical Categories of Root Caused for Breakdowns/Failures

During the BDA, the team will be required to recommend corrective action based upon root cause(s) identified using facts in the Why-Why analysis. To help prepare the team for this task, it is be helpful to understand the primary categories of root causes for most Breakdowns / Failures. This information will assist in the identification of effective countermeasures.

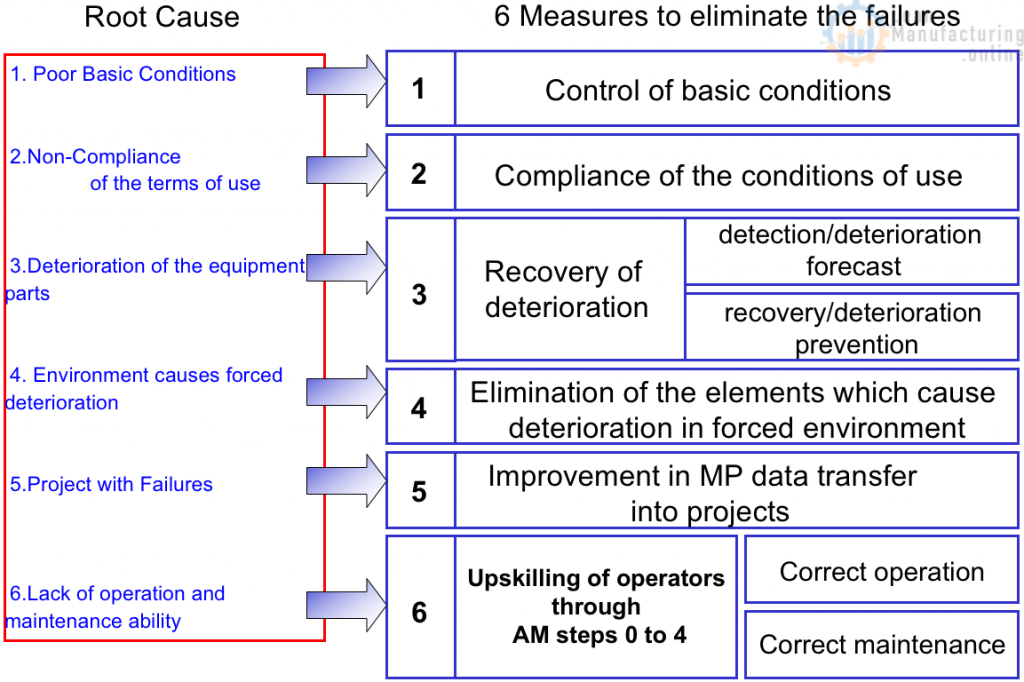

6 Root Causes & Measures to eliminate the Failures

6 Measures to eliminate the Failures

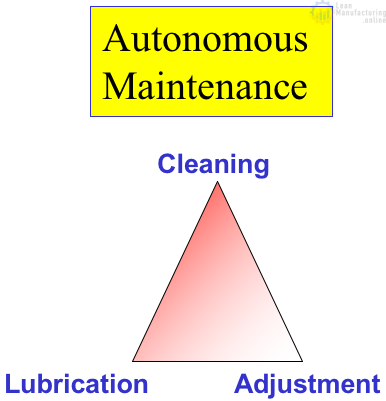

1. Structuring of the basic conditions

Cleaning

- elimination of the causes of the forced deterioration

Lubrication

- elimination of the problems related to lack of oil or dirt in it

- Improvement of the lubrication methods

- standardization of the oil types

Adjustment

- inspection of the nuts and bolts

- measures to prevent loosening

Development of standards for cleaning, inspection and lubrication

Autonomous maintenance activity

2. Compliance with conditions of use

Establishment of operation conditions

- Establishment of conditions such as: pressure, vacuum, temperature, concentration, viscosity, water content, particle diameter, etc.

Standardization of operation methods

- preparation of manuals

- implementation of training “on the job”

Standardization of work adjustments and adjustments

- survey of the adjustment points

- improvement of the adjustment methods – Visual Controls, set points, Poka Yoke

Standardization of the operation at the start and finish (Start-up and ramp-down).

3. Recovery of the deterioration, detection/prevention of deterioration

Inspection of the process through the five senses and detection of the deteriorated parts

Preparation of criteria for routine inspection

Development of standards of inspection and periodic replacement

Establishment of standardized replacement time (hrs or cycles)

Establishment of methods for prediction of abnormalities in the process

Development of control standards

– establishment of reference measurement

– improvement of measuring devices

Establishment of priorities in maintenance work

- implementation of evaluation of equipment

- PM equipment selection

- Develop record of equipment maintenance (CMMS)

- history control

- optimization of maintenance intervals

Standardization of the periodic maintenance on-going on the equipment

- annual calendar

- introduction of electronic data processing (CMMS)

Standardization of the process of disassembly, assembly and replacement

Improvement of an operation method of inspection, repairs and exchanges

Control of spare parts

- common use and centralization (CMMS)

- creation of norms for inventory control

Control of schematic drawing and documentation

common and centralized use

- improvement of the access method

4. Elimination of the elements in the environment which cause forced deterioration

Measures against the sources of dirt

- Detection of sources

- General inspection of scattering dust points

- General inspection of dust collection installation

- Improvement of the dust sources, liquid and gas leak

- Elimination of accumulated dust from buildings and structures

Measures against places of difficult access

- Survey of the areas of difficult access for inspection and measurement

- Survey of inconvenient places in the lay-out

- Specific Improvement for difficult access places

Support for the improvement of the sources of dirt and places of difficult access run by Autonomous Maintenance

5. Improvement of the equipment problem points

Improvement of the peculiar problem points of the equipment arising from project and assembly failure

- measure, degree of precision, material type, resistance, structure and function

- format (slope on the transport lane, etc)

- Corrosion resistance, wear resistance, (Dissimilar metal Corrosion)

Improvement of problem points related to the work environment

- Research of anti corrosive paints

- Research of new materials resistant to corrosion

- Research of coating material

Process improvement

- Nozzle design – anti clogging or self-cleaning

- Increase in the process capability

- Measure against overload

Recurrence of a serious accident

- Measures against similar accidents

6. Upskilling of operators through AM steps 0 to 4

Preparation of manuals about physical changes and operational conditions

- indication of the correct adjustment value

- strengthen the visual control

- indication of flow direction and the contents of the pipelines

- indication of the opening and closing process for the valves and registers

- indication of operation range,measurement instruments manuals

Prevention of erosion of the measures adopted during abnormalities

- standardization of the measures to be taken

- standardization of the method of prediction

Safe operation

- interlock (LOTO)

- indication of open or closed switch

- improvement of emergency stop method

- strengthening of the activity to prevent danger

7. Enhancement of operation and maintenance ability level

Prevention of maintenance errors

- analyses of recurrence of failures

- improvement of maintenance methods

- creation of norms and standardization for material selection

- use of commom spare parts and materials

- development of norms for execution order

Prevention of errors and error monitoring

- increase of the supervisory capacity

- creation of supervisory norms

- system structuring for operation and maintenance supervision

Errors prevention of the experimental operation

- standardization of the experimental operation

- elaboration of the checklist to verify the experimental operation

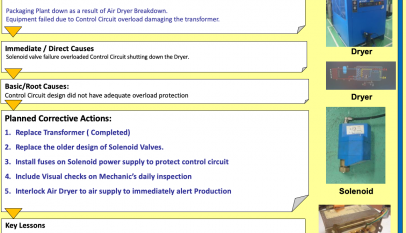

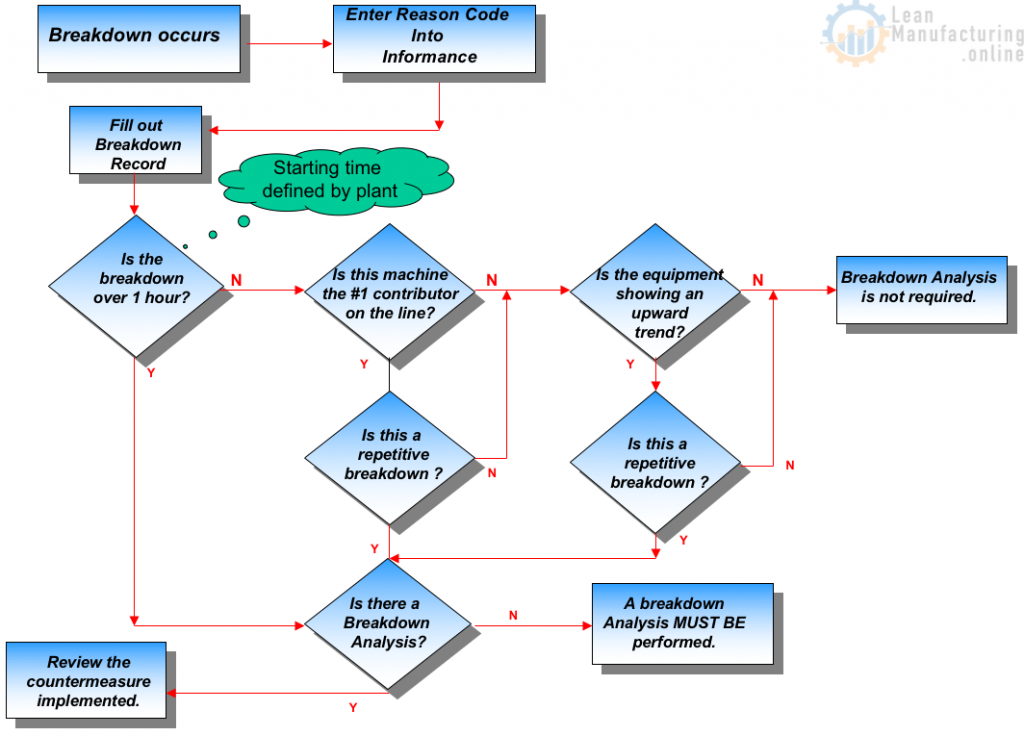

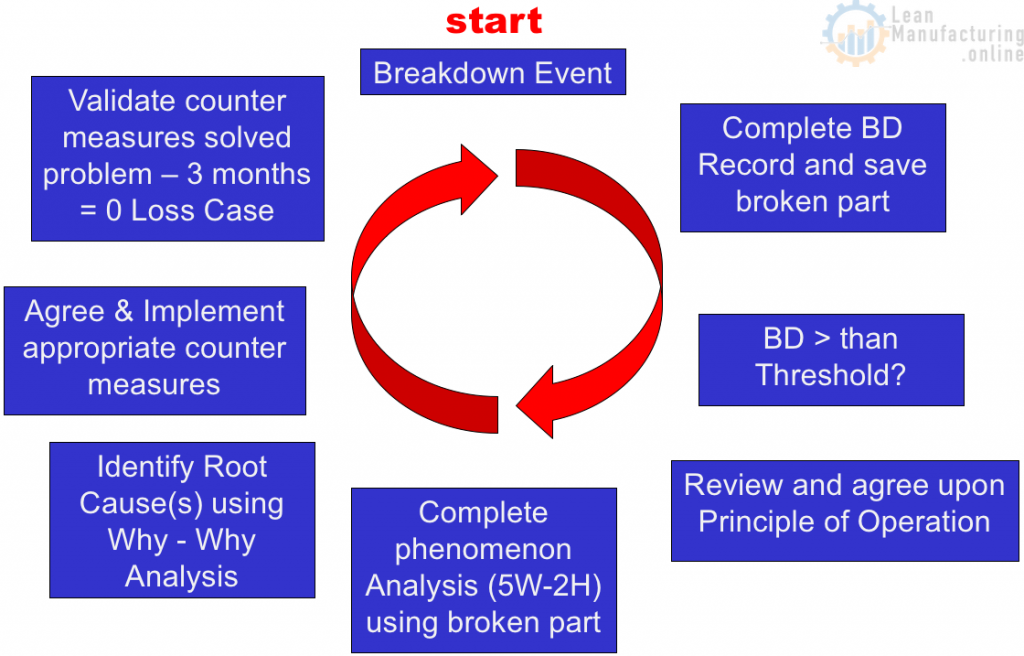

Breakdown Record & Analysis Flowchart

BDA Process Steps

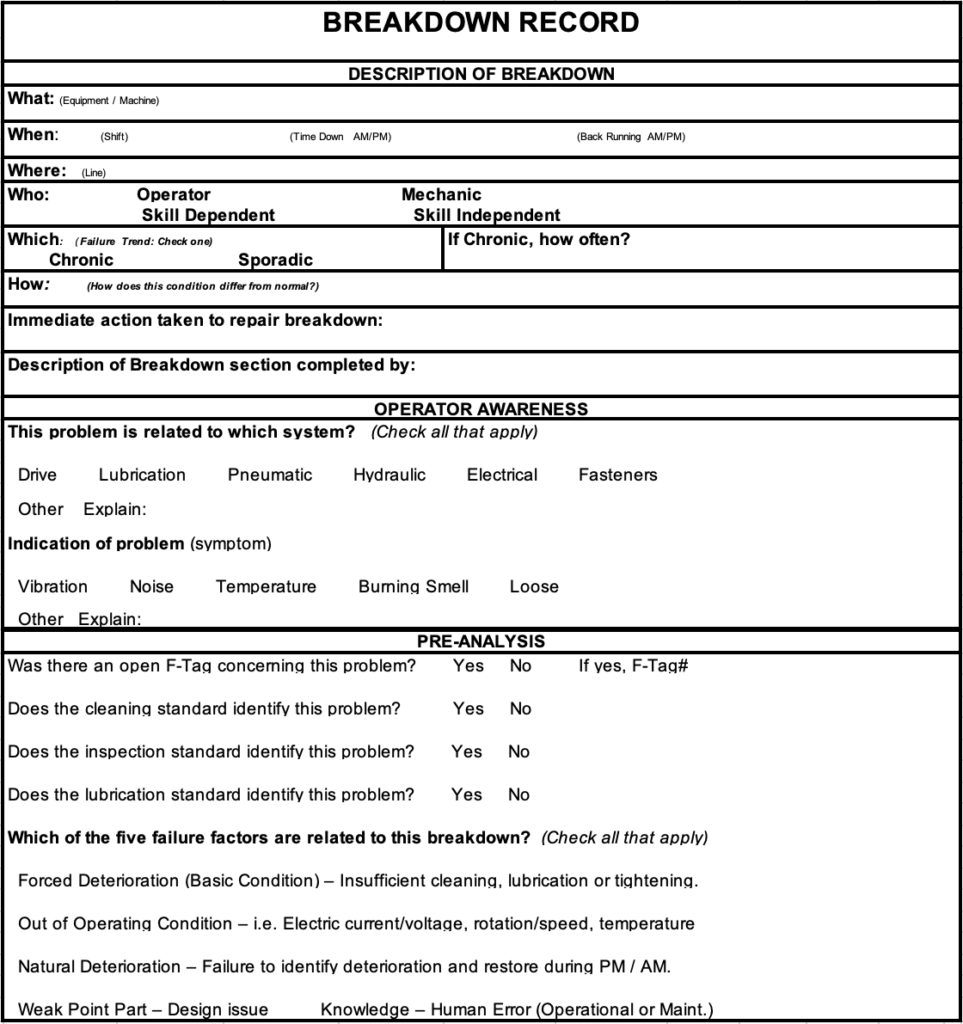

Breakdown record

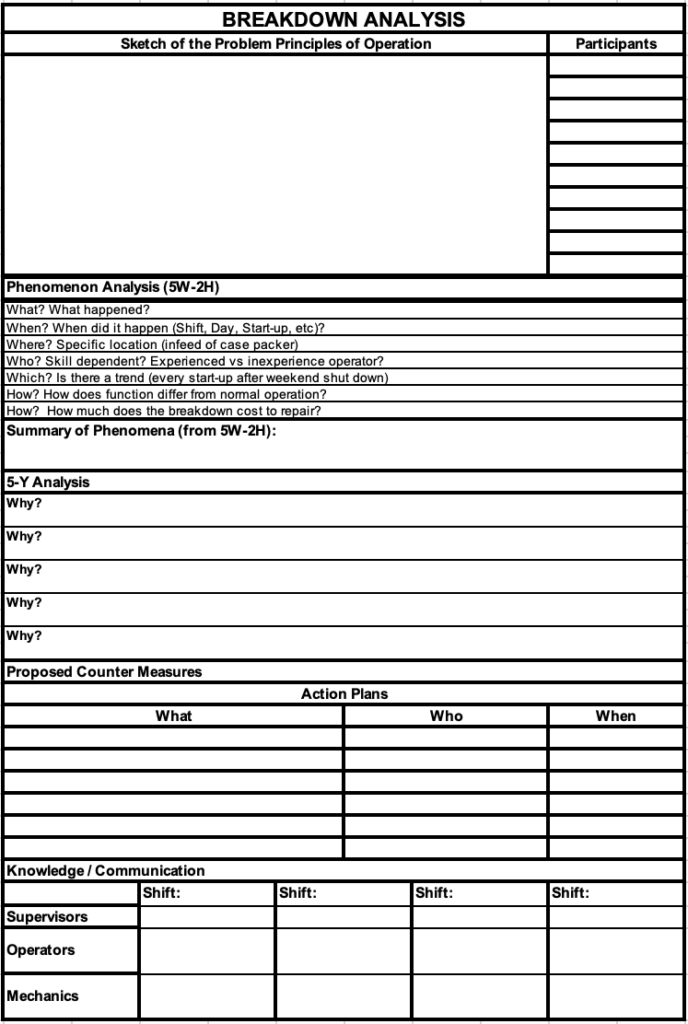

Breakdown analysis

Principles of Operation

- Follow the process flow for the area where problem was seen on the line – (Breakdown Record)

- Identify how each step functions and what purpose does it do.

- Identify what conditions must be in place for each step to function properly, e.g. Temperature, speed, pressure, adjustment, etc.

- Agree as a team, when in doubt, go out to shop floor and confirm. Principles of operation (POO) should be factual….Not what I think happens.

Do not move to the next step until this POO is completed.

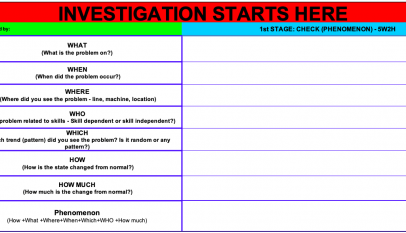

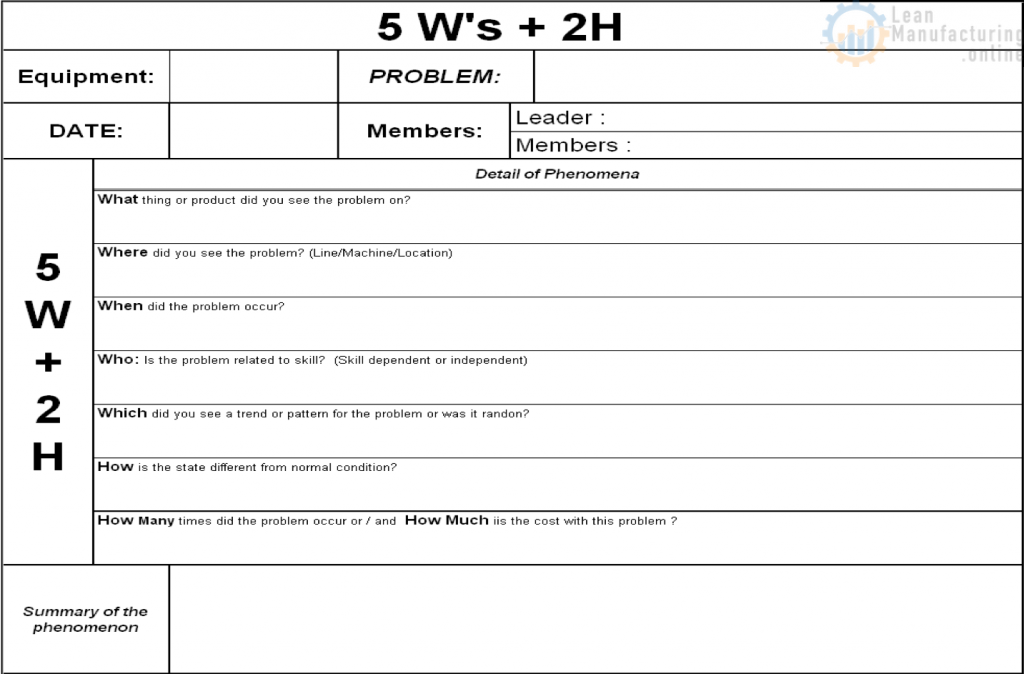

Phenomenon Analysis (5W 2H)

- What – What specific thing (e.g. product/part) are you seeing the problem on?

- When – When have you seen the problem? (Start-up, Ramp Down, normal production, after a changeover, shift, time, etc).

- Where – Where are you seeing the problem? (e.g. packing line, equipment, specific location, material or activity)

- Who – Is the problem related to the skill of anyone? (e.g. New operator, skill dependent or independent)

- Which – Which Trend (pattern) are you noticed the problem e.g. increasing frequency, look at historical data to determine if pattern exists

- How – How does the problem differ from normal operation or ideal state

- How Much – How often does the problem occur and how much to correct? How much waste/loss is generated due to the problem?

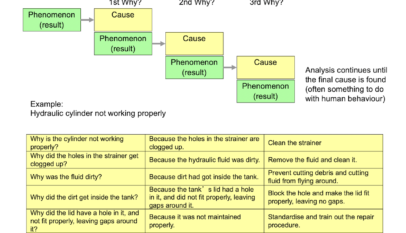

Link between Phenomenon Statement and Why Why Analysis

- After completing the 5W-2H form, this information is used to construct a phenomenon statement – The specific problem to be solved.

- The phenomenon statement is then transferred onto the Why-Why analysis form.

- Now ask the first Why…..Why is the problem happening?

- All answers should relate directly to the specific problem identified in the 5W-2H. Any answers not relating are “out of scope’ and will not lead to a solution. They will only cause confusion and delay. Get rid of them.

But ……What Breakdowns do we start analyzing first?

If not much information is available to start with?…use these rules of thumb:

- Select the TPM pilot equipment first

- Select equipment critical to your operation – A Asset

- Select equipment linked to your loss tree – Largest BD loss

- Select equipment you will have resources to analyze (labor & material)

- Select equipment with unexpected failures first, then equipment with repetitive failures or showing upward trend of occurrences

- Select equipment with no redundancy in place

- Select Breakdowns with the longest downtime

- Select equipment affecting the business the most

Ok, …so what do we do once found a breakdown matching the criteria we selected?

- Verify the data you have is reliable.

- If a Breakdown record has been completed. Use it as input into the process. Hopefully, AM / PM working together are already completing BD records for all Breakdowns over 1 hour. (Perhaps adjust the CMMS work orders to log the same information as in the Breakdown Record form.)

- Bring the Operators into the process !

Teach and allow the operators to initiate the breakdown record with help from the crafts in the area.

Get Started!!!!

How to register and analyse the breakdowns?? Rules and Tips:

- It is the responsibility of the line operators or area mechanics to ensure the breakdown record is completed at the moment the breakdown happens to capture the facts as best as possible.

- It is necessary for the operator and mechanic who acted in the breakdown to fill out the front of the breakdown record as completely as possible. This will improve the quality of input into the BDA

- The maintenance supervisor has the role to verify the status and use of the breakdown record. Insure information is accurate.

- Rules to analyse a breakdown will be = or > than 60 minutes; (This can be changed by the site to meet their level of TPM progression)

- Operators are in charge for tagging the breakdowns/failure in the DT System (Informance) with the correct reason codes. This information can be used as input into BDA

- The target for complete BDA review should be up to 8 days, from the date of the occurrence (This can be adjusted by the plant to meet their needs)

- Fill out all the BDA form trying to get information from specialist; or operators who witnessed the breakdown

- The supervisors responsible for the lines should constantly monitor the line breakdown records to insure they are completed properly;

- The maintenance team will visit daily the areas and line checking the BD records;

- The operators should insure adequate quantity of new BD records sheets for the notebooks before supplies run out. Include this into line 5S standards.

Before you start to solve the problem!

The key to success is to have a Crystal Clear Understanding of Equipment to be Analyzed before Problem Solving Starts.

- Make sure everyone (mechanics and operators) understand and agree upon the sequence and principles of operation before problem solving

- Use video camera to help with this or go to shop floor to insure everyone fully understands the principles of operation

- All settings and adjustments required for this mechanisim to work properly should be quantified

- Air pressure, Temperature, Vacuum, Adjustment locations, Speed, etc.

- After this is completed, proceed to 5W2H

USING THE 5 WHY´S

Practical Rules for a good 5 WHY´S Analysis:

- DON’T JUMP TO CONCLUSIONS! Remember what Happens when we ASSUME!

- BEFORE ANALYSING THE WHY Why Anslysis go to the shopfloor and do the following:

- Go to the workplace (gemba),

- Observe the real things,

- Observe the real conditions,

- Identify the phenomenon,

- Take a realistic attitude.

Suggestions for the SUCCESS of the Workshop

- Participate in at least one BDA

- Engage operators and mechnics with knowledge of asset on which breakdown occurs

Use Breakdown record and broken part as input into BDA

- Engage Supervisors; Operators, Mechanics in BDA.

- TPM support group should insure the process is being followed

- EVERYBODY SHOULD LEAVE THE WORSHOP ENGAGED AND

AWARE OF HIS OR HER ROLES IN THE WORKING ROUTINE GOING FORWARD!

Validation

- Double check that counter measures were implemented as agreed upon by the team.

- Talk to operators and mechanics to get feedback on performance since counter measures implemented

- Check Informance system to determine if breakdown has been reduced (frequency) or eliminated (Zero Breakdown Case if breakdown has not recurred in 3 month)

- Use breakdown re-occurrence matrix to visually show progress against BD loss