3. Implementing Administrative Focused Improvements

3.1 What are Focused Improvements?

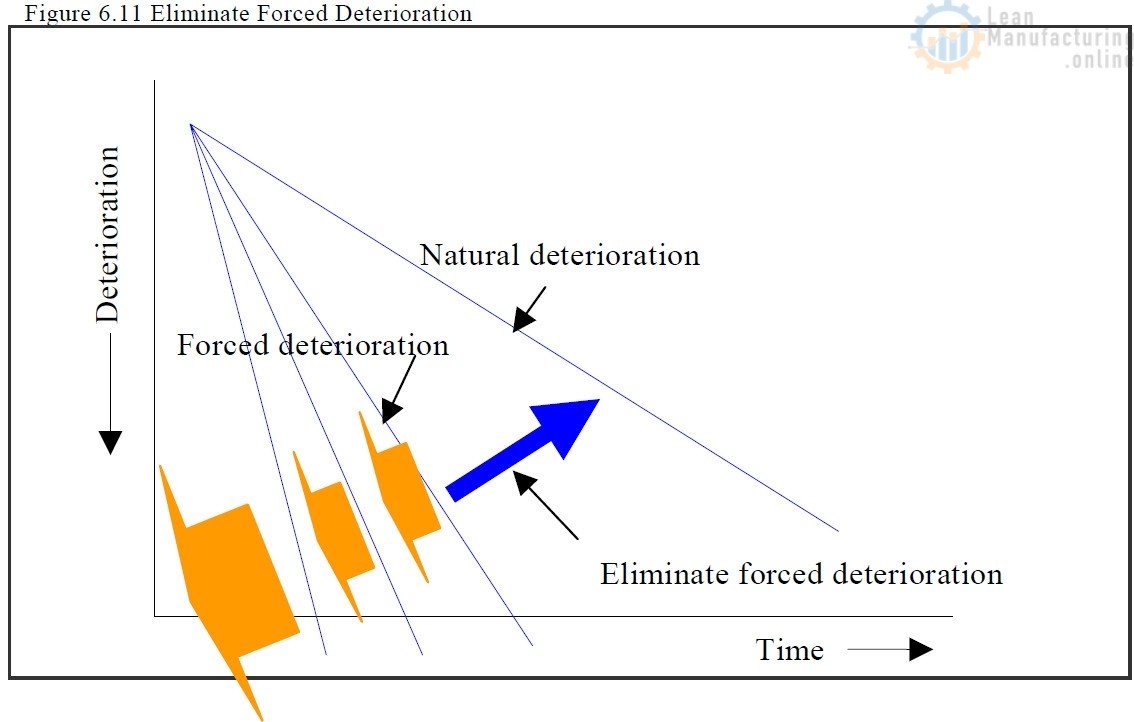

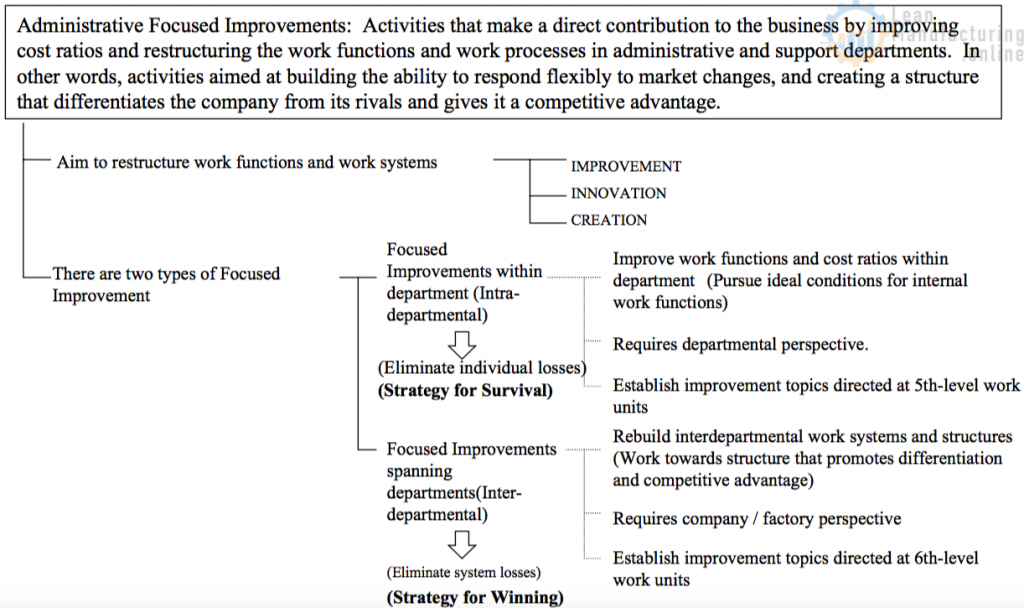

Whereas Autonomous Maintenance in administrative and support departments is aimed at remedial action (i.e. restoring the situation to what it was before it deteriorated), Focused Improvements are all about innovation. What is more, Autonomous Maintenance is weighted towards current administrative tasks (third and fourth-level work units) and establishing basic conditions for those tasks, while Focused Improvements are directed at core work tasks (fifth and sixth-level work units). Focused Improvements are not just about correcting deficiencies in the current work setup. They embrace the wider objectives of restructuring work functions and work processes, improving cost ratios (e.g. the ratio of purchasing costs to sales revenue), and building the capacity to respond to market changes through a structure that favors differentiation and competitive advantage. A Focused Improvement is a ‘surgical operation’, designed to produce immediate results that contribute directly to the business.

If Focused Improvements are to produce a direct positive output to the business, then they must encompass two different perspectives – the departmental perspective and the company or factory perspective (these perspectives are also required in Autonomous Maintenance but to a lesser extent.) The optimal work situation is drawn up based on these two perspectives (the optimal situation for internal departmental work – eliminate individual losses; the optimal situation for interdepartmental work – eliminate system losses), and the disparities between the current and optimal situation are identified as losses and taken up as improvement topics. For each improvement topic, a project team is put together and improvements are implemented. This is how Focused Improvements work.

Figure 10.12 Administrative Focused Improvements

3.2 Implementing Focused Improvements

Once the desired range of departmental functions (the departmental vision or mission) has been established, and the optimal conditions for the first and second-level work functions have been identified, Autonomous Maintenance and Focused Improvements follow different paths, as described earlier.

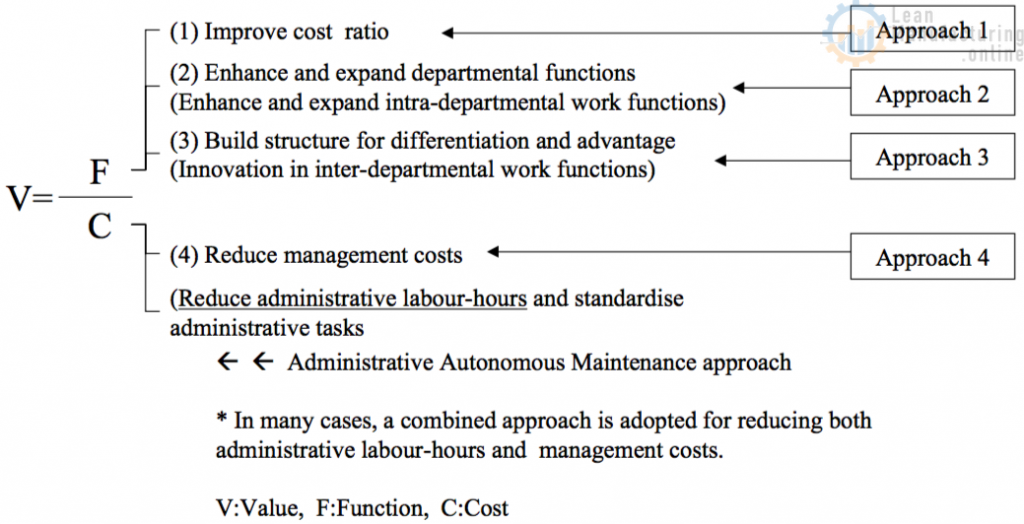

Administrative Focused Improvements can be broadly divided into four categories:

- improving cost ratios;

- expanding and enhancing departmental functions;

- building a structure for differentiation and competitive advantage;

- reducing management costs.

(1) Improving cost ratios:

Through improvements aimed at eliminating losses, each expense element in the total costs will become smaller in ratio to the sales revenue. This reduction in costs helps to give better business results.

(2) Expanding and enhancing departmental functions:

Restructure the departmental work functions in line with future business strategy. Take the viewpoints of other departments into account when considering the optimal conditions for the work functions in your own department.

(3) Building a structure for differentiation and competitive advantage

Construct innovative work processes that negate departmental boundaries, based on the quick-response strategy essential for differentiating the company from its competitors.

(4) Reducing management costs

Apply restructuring, outsourcing, etc, to eliminate losses due to imbalance in fixed costs (staff costs, departmental operating costs, etc.) versus sales revenue.

It follows that there are four types of approach to Focused Improvement, each completely different in terms of the objectives of the related activities. Each approach must be applied at the right time (in the first or second year of the TPM program, or when there is a particular business-related need), to yield a steady succession of positive results that translate directly into business success.

Figure 10.13 Improving Value by Increasing Functionality and Reducing Cost

Typical Topics for Focused Improvements

(1) Planning

- Adopt ‘rolling’ system to improve mid-term planning

- Revise procedure for drafting annual plans to enable plans to be drawn up more quickly

- Enhance work monitoring systems, and operate them more efficiently

- Rationalize procedures for creating policy and checking performance

(2) Personnel and General Affairs

- Achieve greater labor stability by improving work environment and conditions for part-timers

- Set up an internal system for cleaning work clothes (e.g. establish a separate laundry firm)

- Systematize long-term personnel plans and training plans

- Establish management competencies and limits of decision-making powers for each post, and apply them

(3) Finance

- Create a decision-making system based on shorter accounting deadlines (monthly, half-yearly, annual, etc.)

- Create a standardized universal budgeting system

- Create a daily performance monitoring system

- Create a system for rapid assessment of estimated and actual costs

- Reduce insurance premiums for products in stock

(4) Production Management

- Shorten production plan lead times through computer-integrated manufacturing (CIM)

- Create manual detailing the responsibilities and authority of each department with CIM, and apply it

- Create and apply daily staffing plans incorporating cost control functions

- Create and apply a production plan that reduces unexpected fluctuations and changeovers

(5) Materials / Purchasing

- Rationalize material supply system and reduce unit costs

- Cut stock levels of outsourced parts and materials

- Achieve maximum economy in spare-parts control

- Develop suppliers who can meet target costs

(6) Research and Development

- Develop technical information search system to help shorten design time

- Achieve totally unattended operation of testing and analysis equipment

- Evaluate assembly characteristics to design products that are easier to make and give greater scope for cost reduction

- Perfect MP design, so that the same problems can never recur

- Improve the speed and accuracy of investment feasibility studies

- Systematize functional evaluation to reduce design lead times

- Prioritize design of outsourced parts with long supply lead times

- Reorganize design reviews to make them quicker and more effective

- Create design tasks that can be carried out concurrently

(7) Production Engineering

- Use mold, tool, and jig designs that are not liable to faults and that facilitate QA

- Improve accuracy of preliminary test run schedules during the commissioning period

- Improve accuracy of preliminary test run schedules in planning improvement work

- Improve design review technology for new products and new equipment, to achieve a more efficient design review process

(8) Quality Management

- Improve efficiency in inspection, measurement, and analysis, and speed up data feedback

- Achieve totally unattended operation of measurement and analysis equipment

- Create a system capable of handling multi-item tests instantaneously

- Improve design review technology to achieve product and equipment designs that facilitate QA and prevent the recurrence of defects

(9) Site Administration

- Reduce staff requirements by streamlining central monitoring system

- Reduce staff requirements by introducing distributed monitoring systems

- Cut costs by bringing engineering work in-house

- Cut costs by making equipment, jigs, and tools in-house

- Cut costs through energy-saving initiatives

- Reduce staff requirements by building equipment maintenance information system

(1) How to improve cost ratios (example of Approach 1)

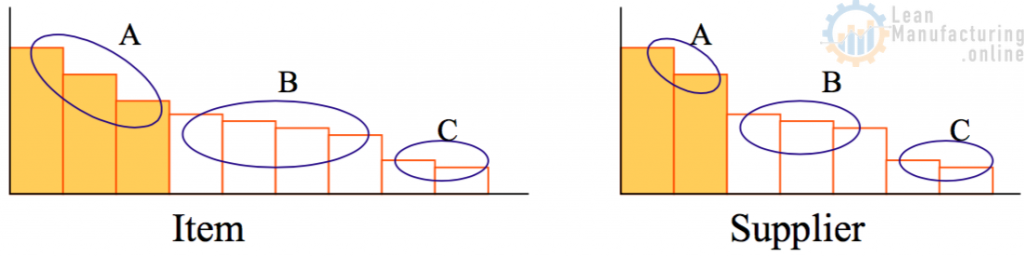

Program for reducing purchasing costs (example)

This program describes a basic improvement approach to purchasing costs. It

is intended as an example, and may not cover all the various elements that makeup purchasing costs (e.g., materials, distribution, dies, etc.)

|

Step 1 |

Survey items, prices, and quantities |

- Confirm business requirements: Check business strategy, business goals, and deadlines specified in mid-term business plans

- Study purchasing (payment) records:

- Analyze items, prices, and quantities

- Study amounts paid to each supplier or dealer

- Clarify where improvements are to be targeted:

- Apply ABC ranking to items

- Apply ABC ranking to suppliers

|

Step 2 |

Establish business goals |

1 Establish secondary business goals: Break down the business goals based on the ABC rankings from Step 1.

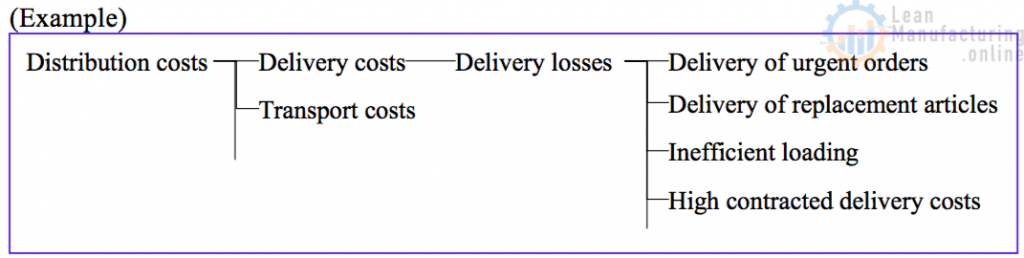

(Example)

Materials Costs Distribution Costs

- Cost of material a

- Cost of material b

- Cost of part c

- Delivery Costs

- Transport Costs

- Packaging/Shipping Costs

|

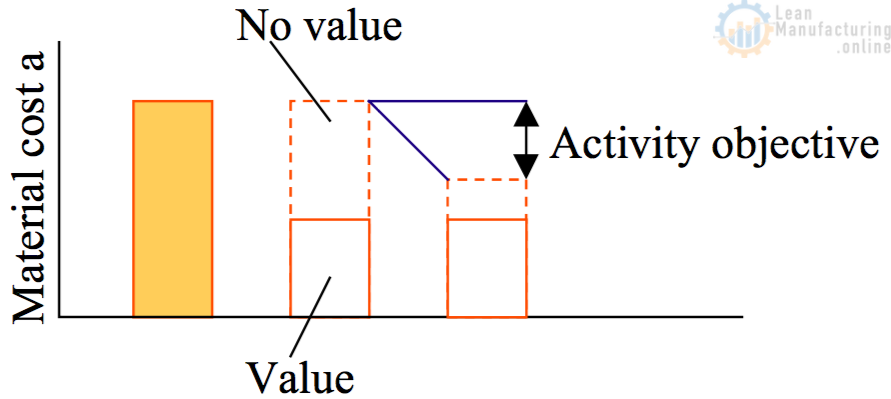

Step 3 |

Perform cost analysis and functional analysis |

1 Analyse ‘value’ and ‘no value’ elements of cost: Dissect costs to see what they are being spent on.

* How to identify ‘no-value’ elements.

- Define ‘no-value’ elements and find them

- Define ‘value’ elements and find them

2 Analyse ‘value’ elements and ‘no value’ elements in functions: Dissect functions to see how they are made up

- Required functions

- Surplus functions (no value)

3 Establish activity objectives

|

Step 4 |

Select and register items for improvement |

1 Identify all the factors that make up the ‘no-value’ elements (i.e. losses) discovered through the cost analysis and function analysis performed in the previous step and register them as items for improvement.

2 Identify all the factors that make up the ‘value’ elements (i.e. required functions) and register them as items for improvement.

(Example)

- Metal castings Make from sheet metal Make from plastic

- Reduce the number of components

3 Make a list of items for the price reduction, from the ABC ranking of payments to suppliers created in Step 1.

4 Where necessary, carry out analysis to elucidate loss mechanisms, and select items to be combated as sources of loss.

|

Step 5 |

Devise improvements |

- Come up with improvement ideas for each item. To start with, identify where an improvement can be made (e.g. ask, “Couldn’t we eliminate/reduce/change that?”), and then develop these thoughts into concrete improvement proposals.

-

Come up with improvement ideas by benchmarking other companies and items

(Example)

Look at best practice in other companies (particularly the way they make things)

Disassemble and compare similar products made by other companies

Compare prices with other companies’ prices and lowest industry prices

-

Create an improvement schedule (with clearly visible ‘milestones’)

|

Step 6 |

Implement improvements and evaluate |

- Implement improvements in your own department, other departments, suppliers, etc. Rigorously control the progress of improvements utilizing intermediate targets and deadlines.

-

Compare the results with the objectives. If they fall short, repeat Steps 4 and 5.

-

Identify the proportion of improvement accounted for by cost reduction and by price reduction (is the improvement due almost entirely to price reduction, for example?)

|

Step 7 |

Consolidate gains and introduce MP |

1 Standardise:

Create rules for sustaining the one-off results that have been achieved through improvement.

2 ‘Professionalise’:

Make sure the standardized rules take root in everyone’s daily work.

3 Move to Maintenance Prevention (MP):

Ensure that the same improvements do not have to be repeated, by implementing complete and thorough systems for preventing losses and avoiding unnecessary functions in upstream work processes, (during design and development, when raising orders, etc.)

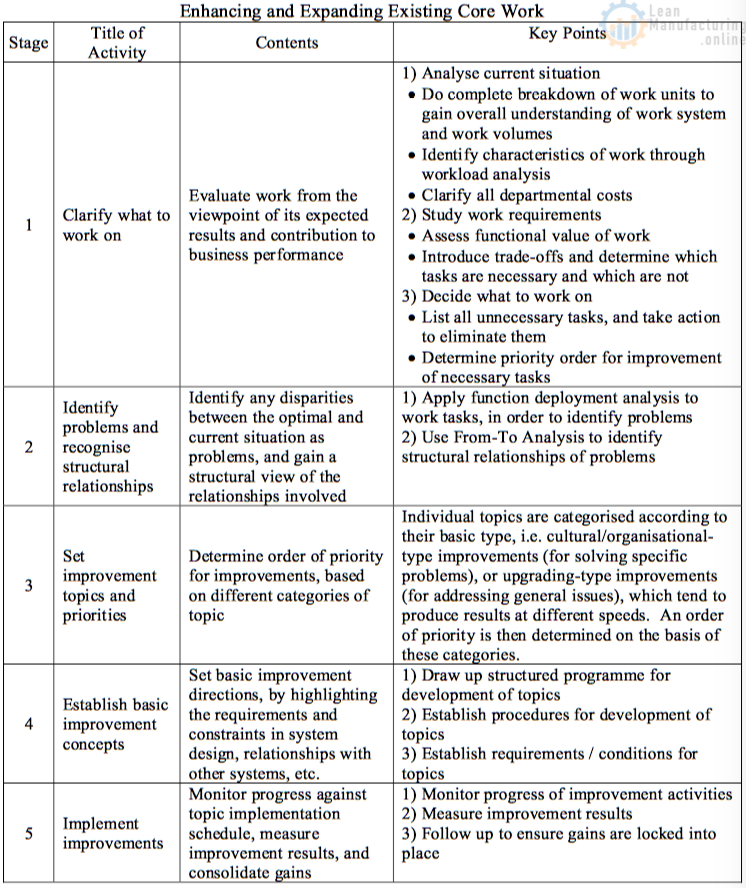

(2) How to enhance and expand departmental functions (example of Approach 2)

To pursue its business activities, a company is divided into various departments and sections forming an organized structure. Each department and section exists so that the company can achieve its business goals and is responsible for some of the organization’s business functions, which in turn constitute the duties and work functions of the department.

However, even though the purpose of departmental work is to accomplish some of the overall business functions of the company, departments frequently overlook this mission and transform into self-serving bodies that focus exclusively on optimizing what they do, as opposed to doing what is best for the company as a whole. This self-centered approach to work responsibilities often gives rise to losses in the business functions, as it leads to conditions being optimized only in a narrow and partial sense.

Situations of this kind must be rectified by restructuring departmental work functions from a broader perspective of global optimization that ensures each department takes on those business functions that it is responsible for. In doing this, the department must also look to the future, by enhancing and expanding its work functions to increase its contribution to the business. The need to create new, unprecedented work functions can arise at any time, and the company must be prepared for this.

A Typical Programme for Enhancing and Expanding Departmental Functions

(3) Building a structure for differentiation and competitive advantage (example of Approach 3)

Example: Improvement of the work process

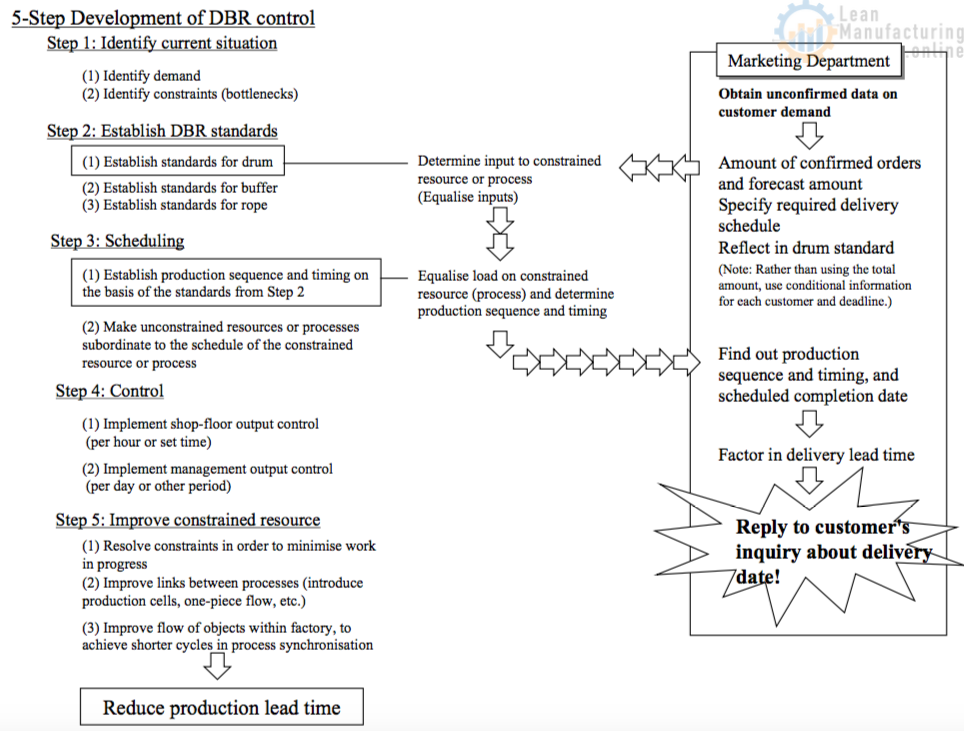

Example of the program for improving the system for responding to customer delivery deadline inquiries

- A program for synchronizing production between different processes (inter-process ‘Drum, Buffer, Rope’ (DBR) control) is developed using a 5-step procedure.

In this particular improvement program, decisions on delivery deadlines are made in Step 2, where the Drum standards (inputs) are established, and Step 3, where the production sequence is decided. This program allows the firm to respond immediately to customers’ inquiries about when they could expect delivery. - This deadline response system applies to a production system that always operates as close as possible to the actual level of demand. It is not the same as a deadline response system for a system in which customer delivery requirements are met by an allocation from stock.

(4) How to reduce management costs (example of Approach 4)

Example of a program for promoting outsourcing

• The objective of outsourcing is to build competitiveness. To be competitive, a company must concentrate its business resources on work within its field of expertise and work that has prospects. Outsourcing is a business technique that helps to achieve this, by actively transferring out any work that would be better done outside the firm. It should be noted that this not simply a cost-cutting or restructuring technique.

|

Step 1 |

Survey in-house resources |

-> Identify strategic business areas and areas for outsourcing

• Use PPM (process portfolio management) to identify the optimal scenario and strategic directions for current and future work

• Survey departmental productivity and identify the desired situation for the future

• Survey departmental work functions and identify the desired situation for the future

• Survey departmental staff levels and work volumes, and identify desired situation for the future

|

Step 2 |

Identify areas of possible outsourcing |

-> Plan ideal personnel and cost structures

- Check work function and work contents relating to strategic operations

- Check contents, and personnel and cost structures of work to be outsourced

- Devise optimal staffing plan for work relating to strategic operations and work to be outsourced

- Study the potential effects of outsourcing on other departments

|

Step 3 |

Choose suppliers |

- Decide the most suitable suppliers for outsourced services, by mutual consent Organise outsourcing department (contact point for suppliers)

- Gather together information and data related to outsourcing (especially about problems)

- Get estimates and plans from various potential suppliers, and receive presentations Create standards for selecting suppliers (e.g. track record of orders, costs, history of problems, etc.)

- Hold selection meeting to decide which suppliers to use

|

Step 4 |

Build an outsourcing system and draw up contracts |

-> Identify company’s outsourcing organizations, and relevant regulations and systems, and sign contracts

- Build an organized system for implementing outsourcing

- Create work regulations relating to outsourcing

Note 1: In particular, clarify core competencies and stipulate that continuous improvement is a work responsibility.

Note 2: Use Autonomous Maintenance to develop and standardize loss-free, problem-free work processes in advance.

- Reach in-house consensus on outsourcing and how it is implemented Note: It is not a cost-cutting or restructuring technique.

- Systematize details of actual work involved in outsourcing, e.g: length of the contract, the duty of confidentiality, cancellation conditions, compensation rules, consultation setup, etc.

- Sign outsourcing contracts

|

Step 5 |

Follow up |

-> Ensure effective and efficient outsourcing

- Arrange regular meetings with suppliers (e.g. every week or fortnight) to prevent potential problems

- Find out the level of staff awareness of outsourcing and identify areas for improvement

- Measure the benefits of outsourcing Evaluate the extent to which initial goals have been achieved and identify points for improvement

- Draw up items for improvement in future contracts, and discuss with suppliers

Practice session

Using this value tree for the sales department as a model, draw up value trees for the purchasing department and the production management department (creating tree: 20 min; presentation: 5 min.).